Plate Heat Exchanger Applications: Efficient Solutions for Heating and Cooling Systems | Heating Formula

Heating Formula specializes in high-performance plate heat exchangers for Heating and Cooling Applications and geothermal applications. Our exchangers deliver fast, efficient heat transfer while minimizing space and energy consumption.

Trusted across industries—from HVAC and food processing to aquaculture and leisure facilities—they ensure reliable temperature control.

With durable options in SS316L, SS304, and Titanium plates, and gaskets in EPDM, NBR, or Viton, our solutions meet diverse operational needs.

Explore how Heating Formula can optimize your system with safe, efficient, and long-lasting heat exchanger technology.

Heating and Cooling Applications with Plate Heat Exchangers

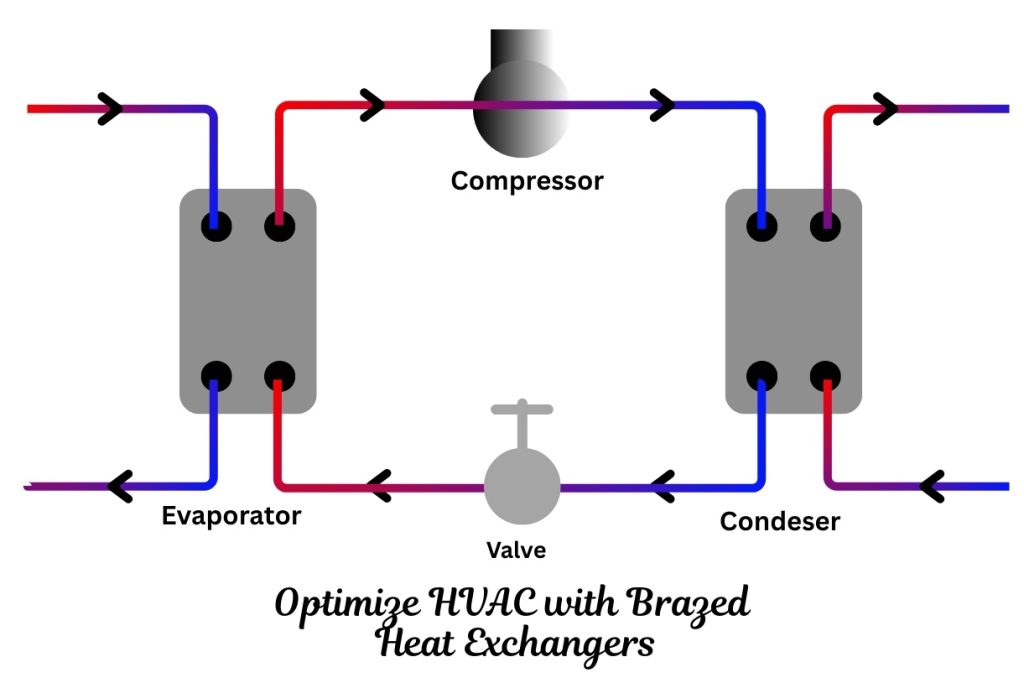

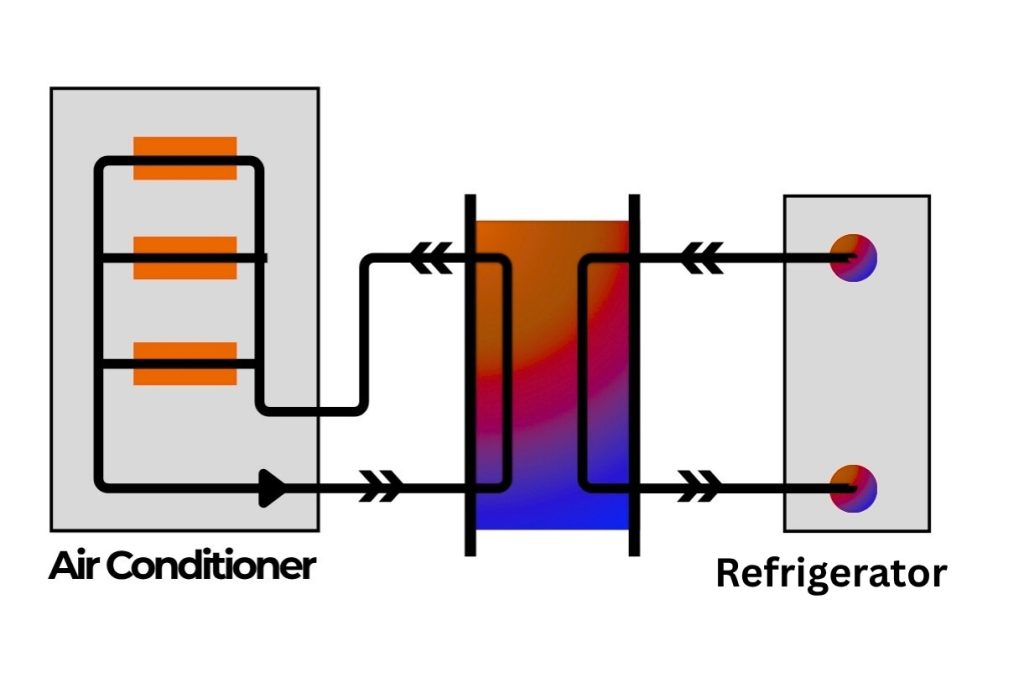

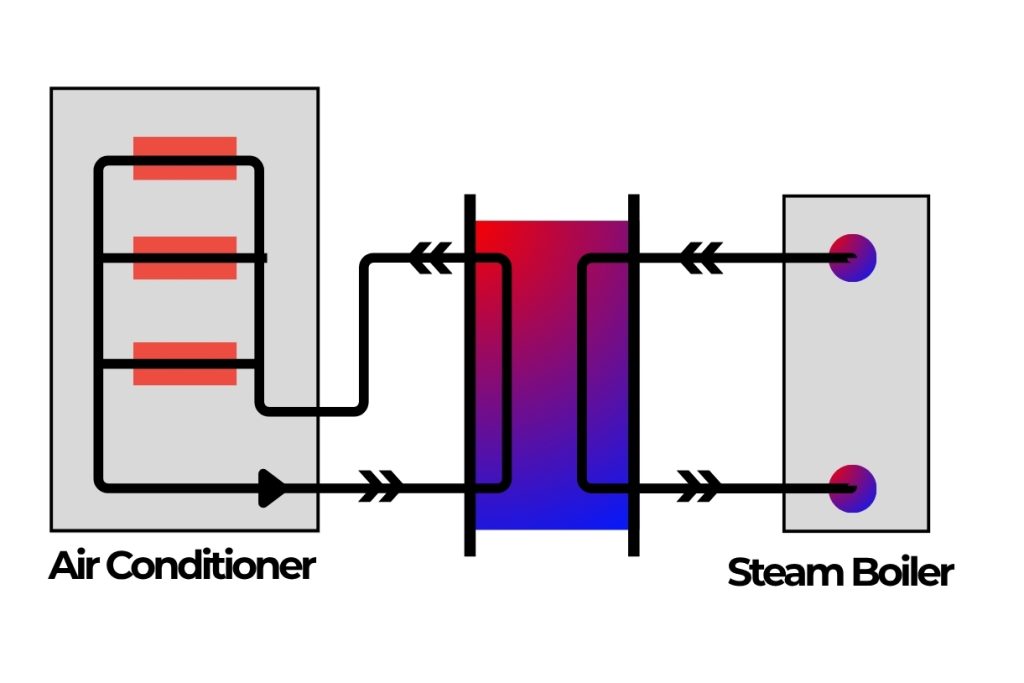

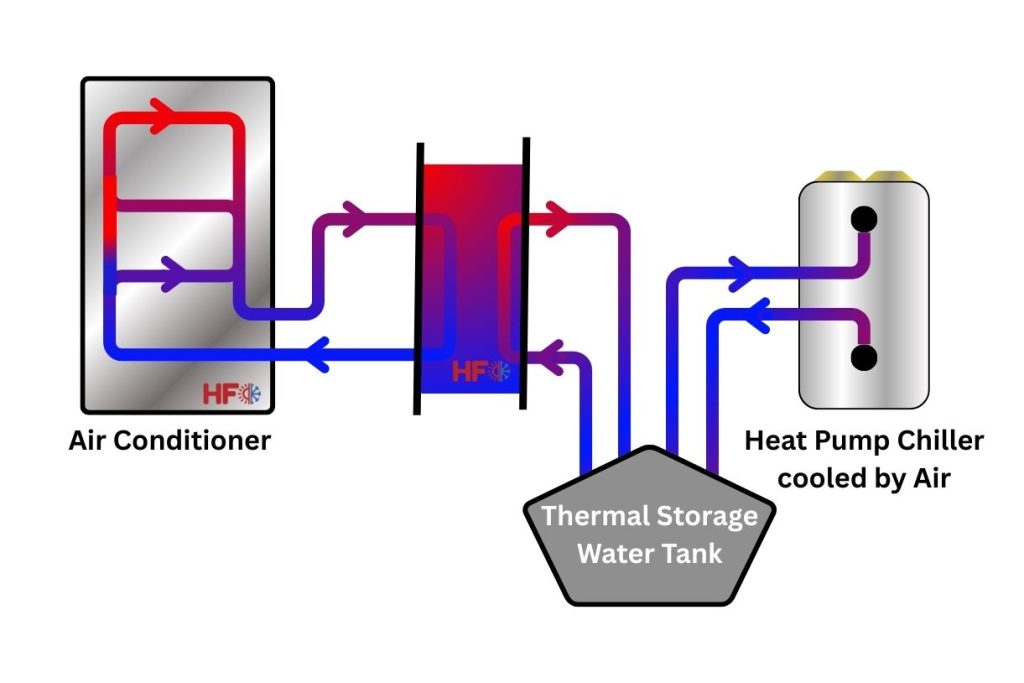

As evaporators and condensers in refrigeration cycles such as refrigerators, chillers, and heat pumps, brazed plate heat exchangers (BPHE) significantly increase efficiency and compactness. Heating Formula units ensure reliable, fast heat transfer from steam boilers and hot water boilers to circulating water in air conditioners.

Heat exchangers from Heating Formula reliably and quickly transfer heat from sources such as steam boilers and hot water boilers to circulating water in HVAC systems. Depending on the application, plates are available in SS316L, SS304, or Titanium, and gasket materials include EPDM, NBR, and Viton to ensure durability, safety, and long service life.

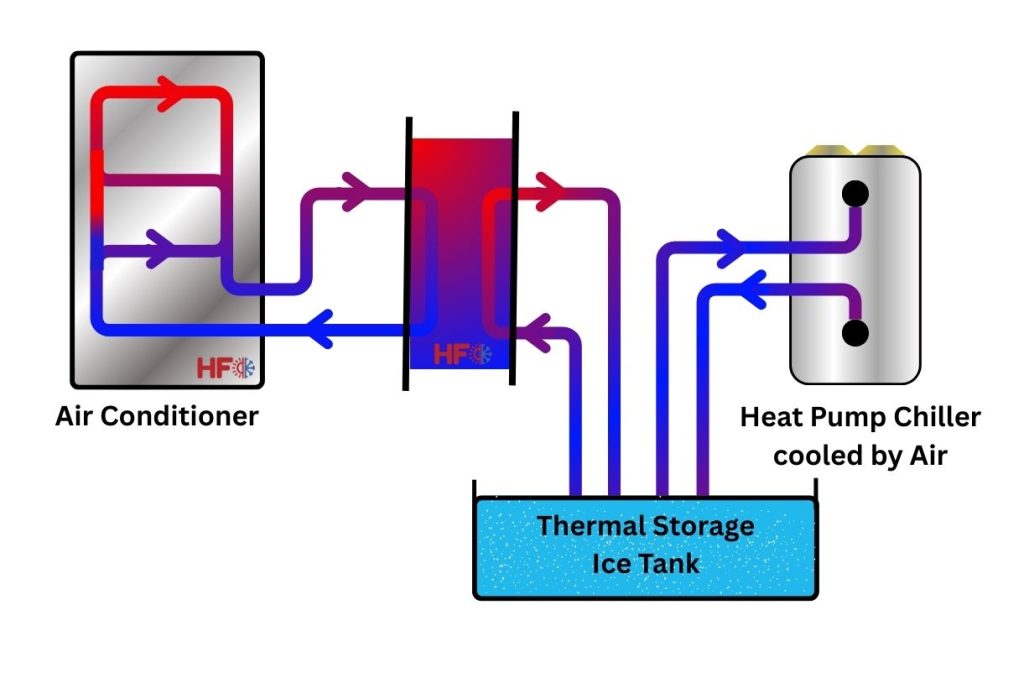

Cold Energy Storage (Water & Ice Thermal Storage)

By using antifreeze liquids (brine) on the circulation side of cold heat sources, Heating Formula plate heat exchangers are ideal for ice storage, heat dissipation, and daytime peak shaving operations. This thermal energy storage method reduces operating costs and stabilizes cooling loads for commercial and industrial systems.

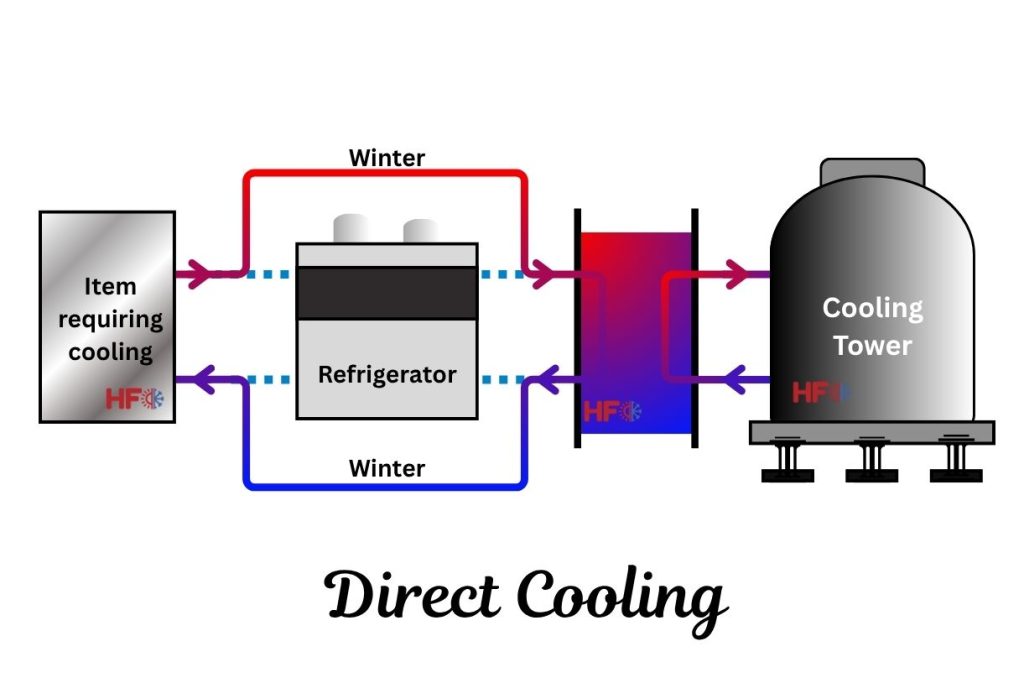

Free Cooling with Plate Heat Exchangers

To reduce operating costs, cooling tower water can be used as a free cooling source during colder months. Heating Formula plate heat exchangers protect chillers from contamination in summer and allow units to shut down in winter, lowering power consumption.

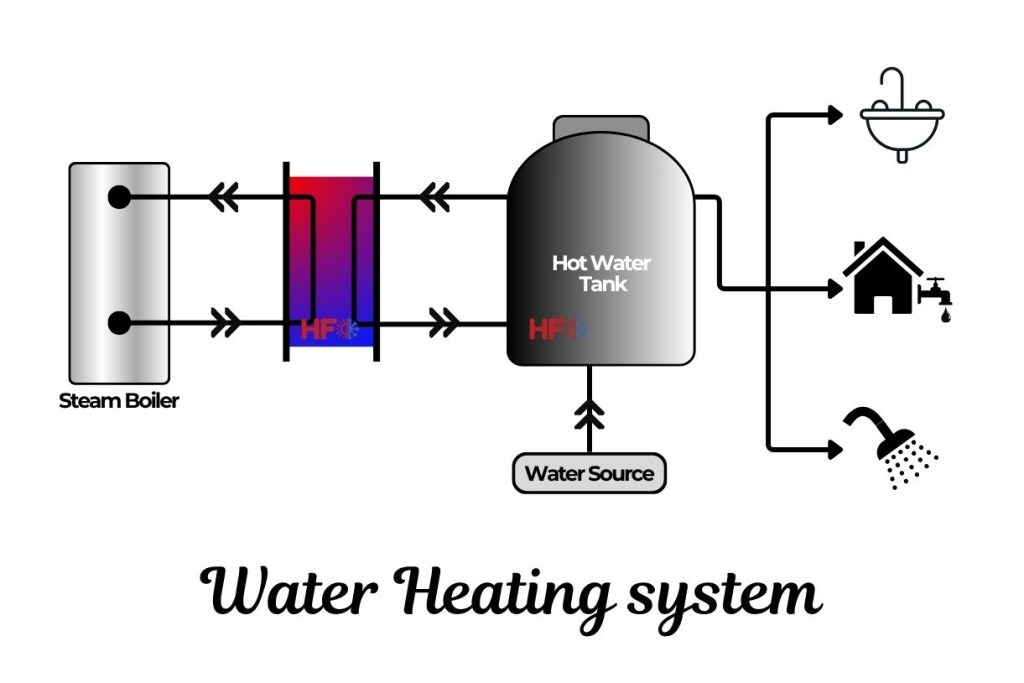

Hot Water Supply Applications

Our compact plate heat exchangers ensure rapid and precise temperature control for hot water supply. The efficient design minimizes water volume while providing hygienic and safe heating, trusted in the food and beverage industry.

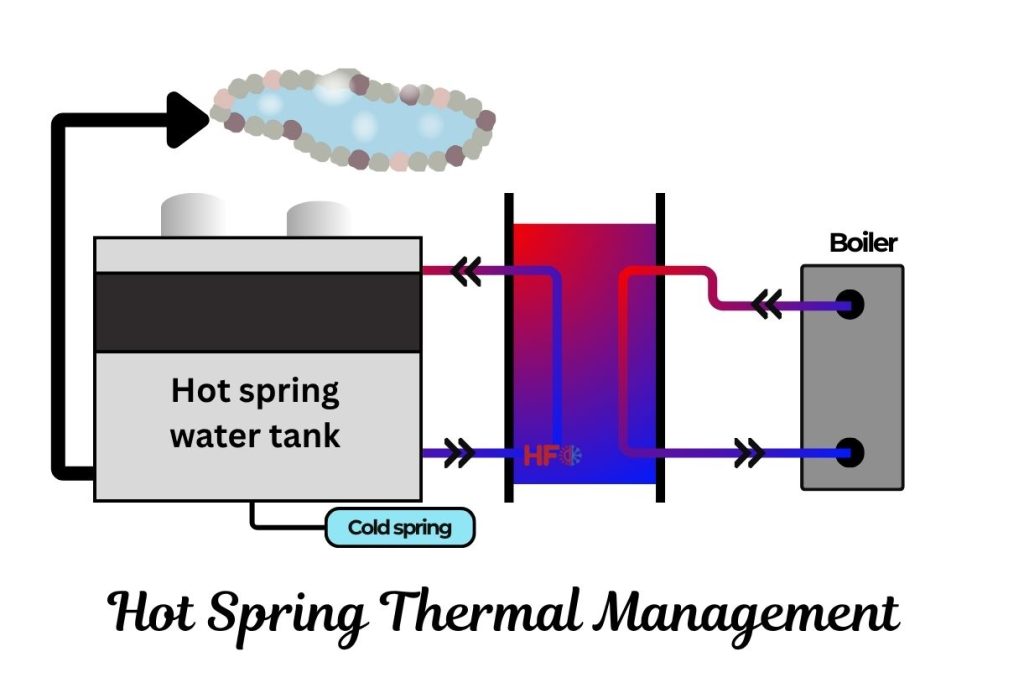

Hot Spring Pools and Leisure Facilities

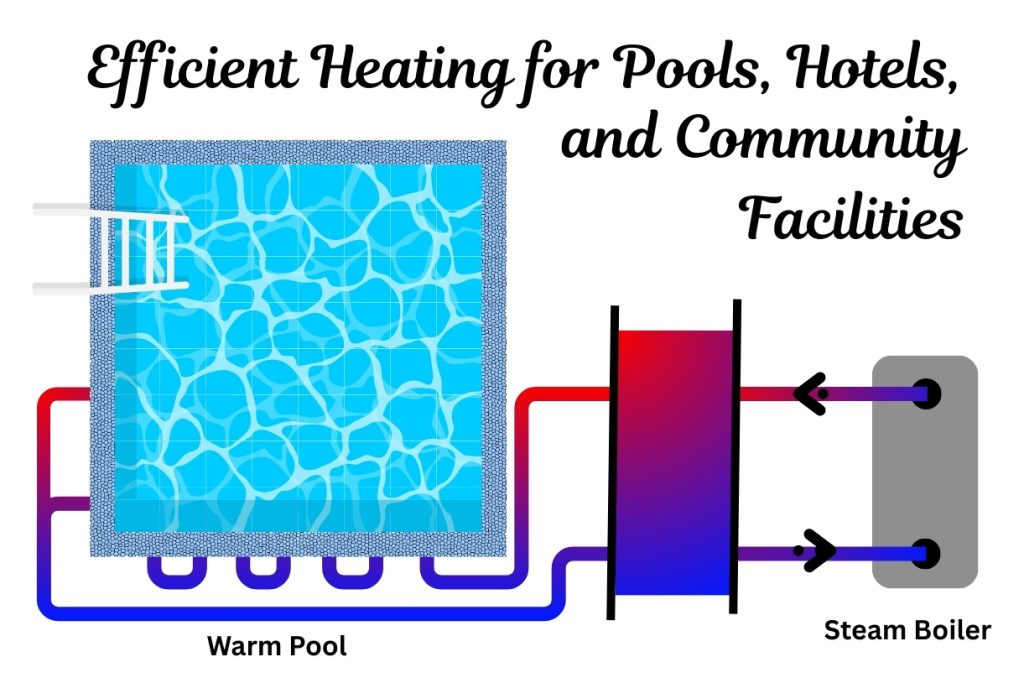

Heating Formula plate heat exchangers are widely used in schools, community centers, sports clubs, hotels, and spa facilities to maintain ideal water temperatures.

With superior corrosion resistance from Titanium plates and reliable sealing with Viton or EPDM gaskets, our systems provide long-term, safe, and comfortable water heating for pools and hot springs.

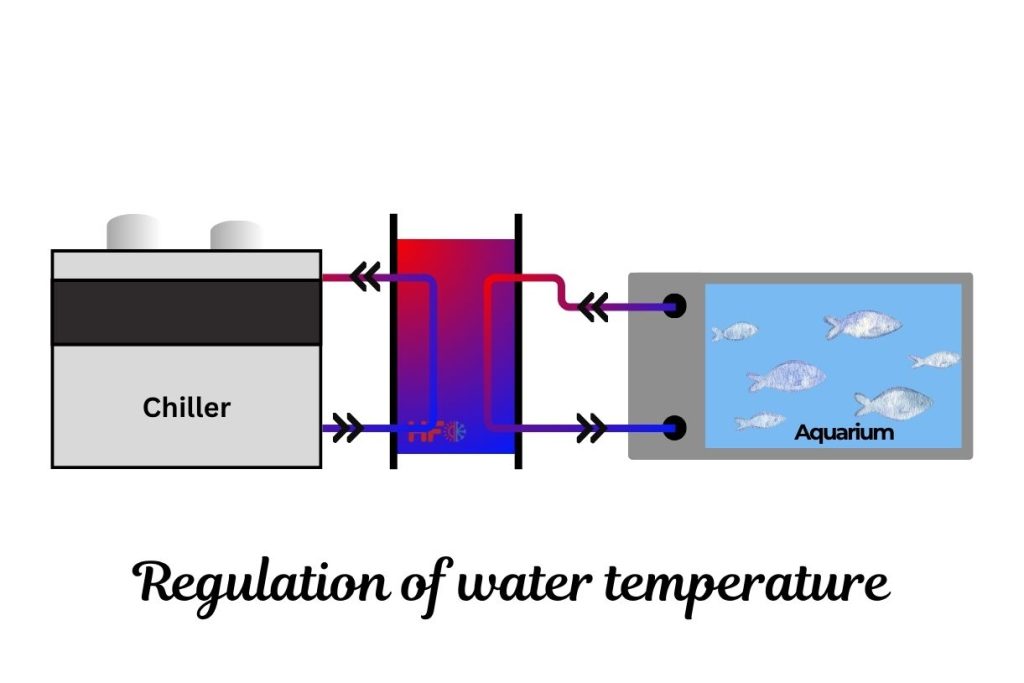

Water Temperature Control

Accurate temperature control is crucial in aquariums, fish farms, and research facilities. Heating Formula plate heat exchangers provide stable and efficient thermal regulation to maintain water conditions essential for marine life.

Melting Snow

Plate heat exchangers are also applied in snow-melting systems. Using the heat from hot spring water or well water, they warm antifreeze liquids (brines) that are then circulated for road heating, railway snow-melt sprinklers, and snow-melt storage tanks.

Durability is ensured by using SS316L or Titanium plates, depending on the water quality, with NBR gaskets providing dependable sealing performance in low-temperature environments.

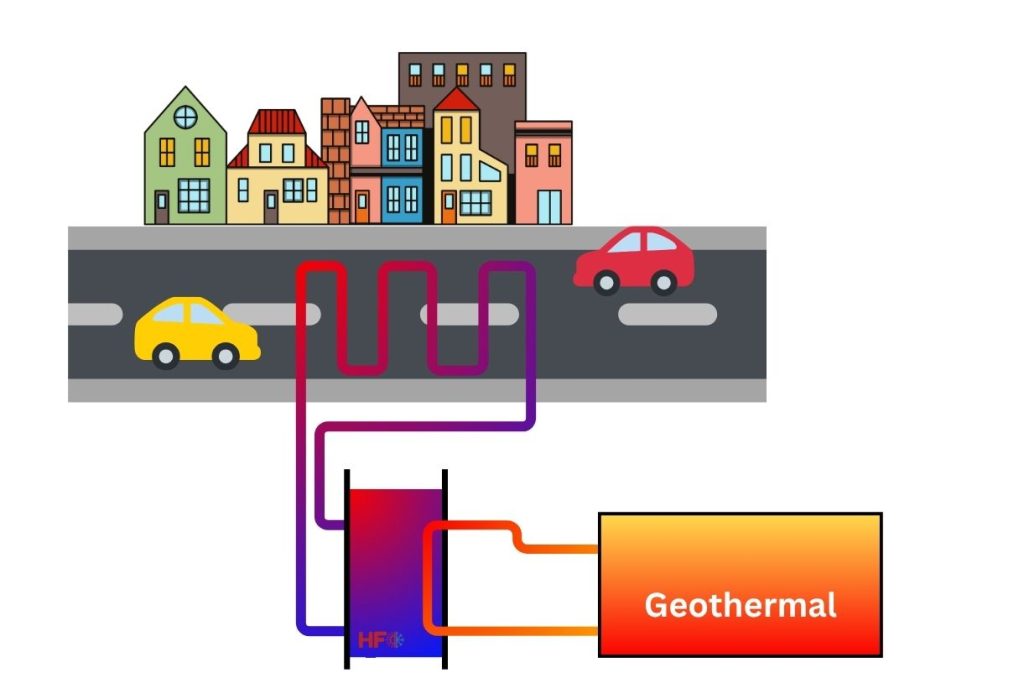

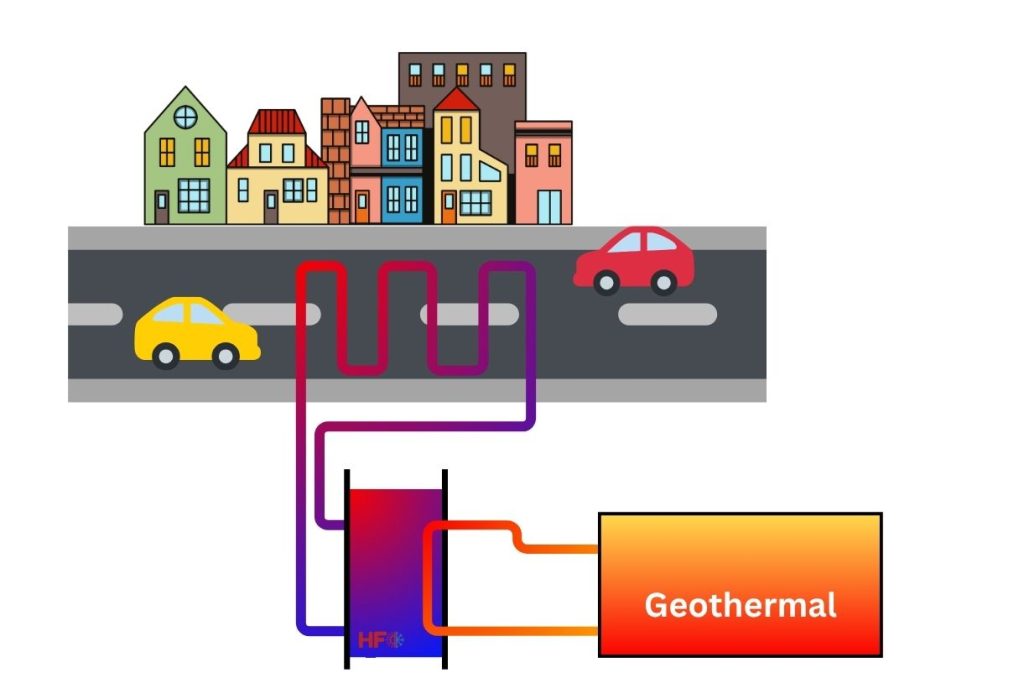

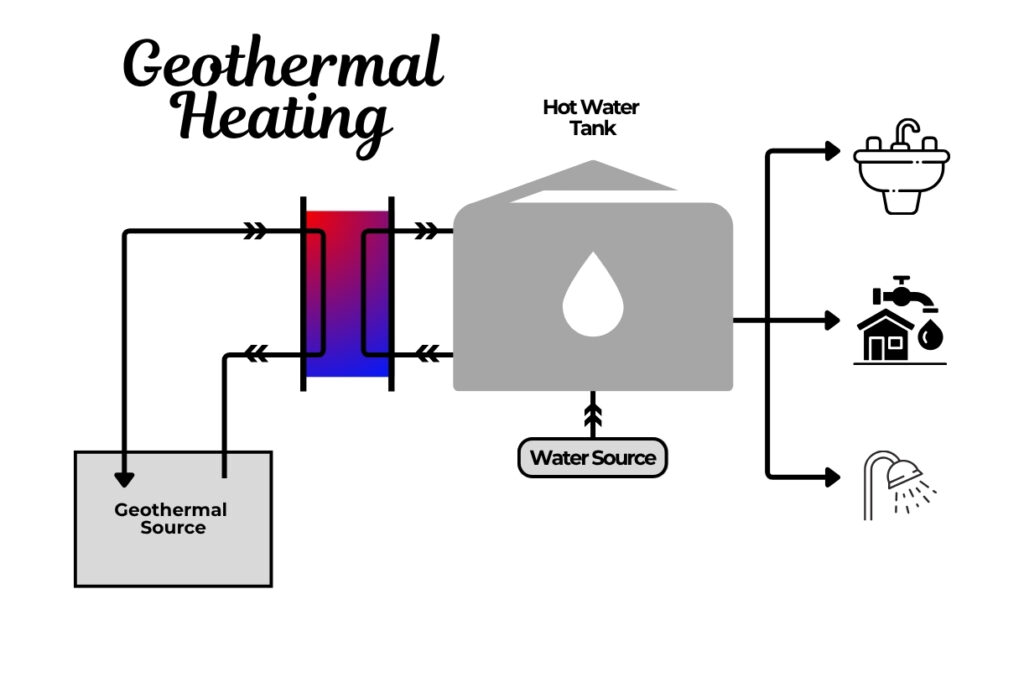

Hot Spring Heating/Cooling, Geothermal Utilization

Harnessing geothermal energy through plate heat exchangers is an efficient way to provide hot water, heating, and cooling while significantly reducing energy consumption.

Titanium plates are especially suited for geothermal use due to their high corrosion resistance. Pairing them with Viton gaskets ensures system longevity and reliability in harsh operating conditions.

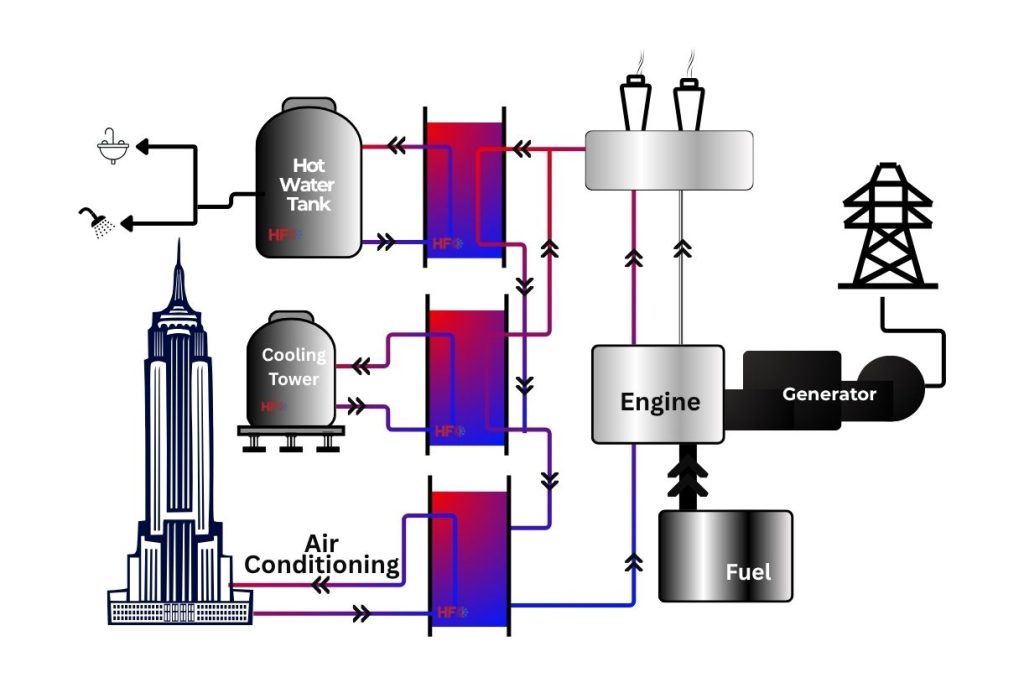

Dual Energy Generation: Power and Heat Together

Heating Formula heat exchangers play a critical role in combined power and heat recovery systems. By recovering exhaust heat from diesel and gas engines, our exchangers provide energy for hot water supply, heating, and cooling, maximizing total system efficiency.

SS316L and Titanium plates with EPDM or Viton gaskets ensure safe, efficient, and long-lasting operation even under high-temperature and high-pressure conditions.

Frequently Asked Questions (FAQ)

Q1: What materials are best for plate heat exchangers?

A: SS316L and SS304 are commonly used for general applications, while Titanium plates are recommended for corrosive environments such as seawater and geothermal systems.

Q2: Which gasket materials should I choose?

A: EPDM is suitable for hot water, NBR for oil-based media, and Viton for chemically aggressive or high-temperature conditions.

Q3: Can plate heat exchangers save energy in HVAC systems?

A: Yes. By transferring heat efficiently and allowing for free cooling in certain seasons, they can significantly reduce operational costs.

Q4: Are plate heat exchangers suitable for food industry applications?

A: Absolutely. With SS316L plates and EPDM gaskets, they deliver hygienic, reliable hot water supply for food and beverage processes.

Learn More

Summary

At Heating Formula, we specialize in delivering high-performance plate heat exchangers with plates made from SS316L, SS304, and Titanium, and gaskets in EPDM, NBR, and Viton, tailored to your exact application. Whether you need solutions for heating, cooling, geothermal, or industrial hot water supply, our experts are ready to help.

Contact Heating Formula today and let us design the perfect heat exchanger solution for your system.

For further trusted information on heat exchanger technology, visit: ASHRAE – American Society of Heating, Refrigerating and Air-Conditioning Engineers.