Keep Your Cool: Why Your Hydraulic Press Needs an Efficient Oil Cooler

In the heart of many bustling Turkish factories, from automotive giants in Bursa to manufacturing hubs across the country, the rhythmic hum of the hydraulic press is a familiar sound. These powerful machines, essential for shaping and forming materials with immense force, have a long history in Turkey’s industrial development. As Turkish manufacturing evolved, so did the technology supporting it, including the critical components that keep these workhorses running: heat exchangers.

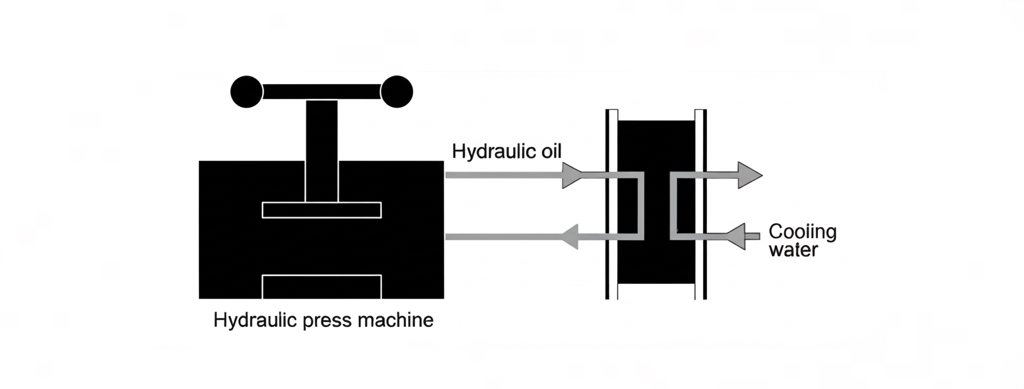

A hydraulic system is the muscle behind the press, using fluid—typically oil—under high pressure to generate the force needed for stamping, forging, and molding. But with great power comes great heat. As the hydraulic oil is pressurized, its temperature rises significantly. Without proper cooling, this can lead to a cascade of problems, from damaged equipment to costly production halts. This is where the unsung hero of the hydraulic system comes in: the oil cooler.

How Does an Oil Cooler Work in a Hydraulic Press?

Think of a hydraulic oil cooler as the radiator for your press machine. Its job is to dissipate the excess heat generated during operation, ensuring the hydraulic fluid remains at an optimal temperature. Most commonly, a shell and tube heat exchanger or a compact gasketed plate heat exchanger (GPHE) is used for this purpose.

The process is simple yet effective:

- Hot Oil Inlet: The heated hydraulic oil is pumped from the press’s reservoir into the heat exchanger.

- Cooling Medium: Simultaneously, a cooling medium—usually water from a cooling tower or a chiller—flows through a separate set of channels within the exchanger.

- Heat Transfer: The hot oil and the cooling water flow on opposite sides of thermally conductive plates (in a GPHE) or tubes (in a shell and tube exchanger). Heat naturally transfers from the hot oil to the cooler water without the two fluids ever mixing.

- Cooled Oil Outlet: The now-cooled hydraulic oil is circulated back to the reservoir, ready to be pressurized again.

This continuous cycle is vital for maintaining the stability and longevity of the hydraulic system. You can explore various configurations and find the perfect match for your system with our GPHE Selection tool.

What Happens if the Hydraulic Oil Overheats?

Operating a hydraulic press with oil that is too hot is a recipe for disaster. High temperatures degrade the oil, reducing its viscosity and lubricating properties. This can lead to:

- Seal and Gasket Damage: Overheated oil can cause seals and gaskets to harden, crack, or even melt, leading to significant leaks. As we’ve discussed in our “Troubleshooting for Plate Heat Exchangers” article, aged and hardened gaskets are a primary cause of external leakage.

- Reduced Equipment Lifespan: Poor lubrication from degraded oil causes increased friction and wear on the pump and other critical components, leading to premature failure.

- Inconsistent Performance: A change in oil viscosity can affect the press’s performance, leading to inconsistencies in product quality.

- Unplanned Downtime: A system shutdown due to overheating can halt production for hours or even days, resulting in significant financial losses.

To prevent these issues, it’s crucial to select the right oil cooler and maintain it properly. Our guide on “How to balance budget and performance in heat exchanger selection” can help you make an informed decision that saves you money in the long run.

Why is a High-Quality Heat Exchanger Essential for High-Pressure Systems?

Hydraulic presses operate under immense pressure, and the heat exchangers in these systems must be robust enough to handle the stress. Shell and tube heat exchangers are traditionally known for their ability to withstand high operating pressures. However, modern gasketed plate heat exchangers have also been engineered for high-pressure applications and offer superior thermal efficiency in a more compact footprint.

The efficiency of your oil cooler directly impacts your bottom line. A highly efficient heat exchanger, like those offered by Heating Formula, can cool the oil using less water and energy, reducing your operational costs. Innovations in plate design, such as special corrugations, create more turbulence in the fluid flow, which enhances the heat transfer coefficient and helps prevent scale buildup on the plate surface.

For a deeper dive into how design affects efficiency, our post on “How advanced thermal hydraulics solve your process efficiency challenges” provides valuable insights.

Can I Recalculate and Reuse an Old Heat Exchanger?

In the dynamic world of manufacturing, production needs can change. Sometimes, a heat exchanger may no longer be suitable for its original task. But that doesn’t mean it’s destined for the scrap heap. It is often possible to recalculate an old unit for a new purpose. This process involves analyzing its heat transfer area, flow rates, and material compatibility to see if it can be adapted for a different application within your plant. Our powerful Heat Exchanger Calculator is an excellent tool to help you determine the feasibility of repurposing your existing equipment. Recalculating an old exchanger can be a cost-effective and sustainable solution compared to purchasing a new one.

Your Partner for Reliable Hydraulic Cooling Solutions

At Heating Formula, we understand the demanding environment of industrial manufacturing. We specialize in providing high-quality Gasketed Plate Heat Exchangers (GPHEs) and Shell & Tube heat exchangers designed for the rigors of hydraulic press operations and other industrial applications.

Whether you need a new oil cooler or are looking for reliable spare parts, we have you covered. We offer a comprehensive inventory of GPHE Spare Parts, including plates made from durable 316/304 Stainless Steel, Titanium, and high-nickel alloys like C-276 Hastelloy and 254 SMO. Our gaskets, available in EPDM, NBR, and Viton, are designed for longevity and optimal sealing performance.

Our spare parts are fully compatible and equivalent to OEM brands such as Alfa Laval, Sondex, APV SPX, Funke, Schmidt, Vicarb, Gea, and Tranter, ensuring you get the quality you trust at a competitive price.

Don’t let an inefficient or failing oil cooler become a bottleneck in your production. Contact Heating Formula today to discuss your hydraulic cooling needs and discover how our solutions can enhance your efficiency and protect your valuable equipment.

Frequently Asked Questions (FAQ)

What are the first signs that my hydraulic oil cooler is failing?

The most common signs include a gradual increase in the hydraulic oil operating temperature, a noticeable drop in pressure within the heat exchanger, or visible fluid leaks around the unit. Monitoring these parameters regularly helps you detect issues like fouling or gasket deterioration early, preventing major breakdowns.

How do I choose between a plate heat exchanger and a shell and tube heat exchanger for my hydraulic press?

The choice depends on your specific needs. Gasketed Plate Heat Exchangers (GPHEs) are generally more thermally efficient and have a much smaller footprint, saving valuable plant space. They are also easier to open and clean, which is a major advantage for maintenance. Shell and Tube (S&T) heat exchangers are traditionally known for their ruggedness and ability to handle very high pressures and temperatures. For most modern hydraulic applications, a GPHE offers a more compact and efficient solution. You can explore your options on our GPHE Selection page.

How often should I replace the gaskets on my plate oil cooler?

Gasket lifespan depends heavily on operating conditions like temperature, pressure, and the type of hydraulic fluid used. As a general guideline, for operating temperatures between 30°C and 100°C, gaskets should be inspected and possibly replaced every 5-7 years. For higher temperatures, the interval is shorter. Regular inspection for hardening, cracks, or brittleness is key. We offer high-quality replacement gaskets for all major brands in our GPHE Spare Parts section.

What is the difference between 316 stainless steel and titanium plates? Which one do I need?

The choice of plate material depends on the cooling medium you use. 316 Stainless Steel is a versatile and cost-effective choice suitable for most standard applications using treated water or closed-loop cooling systems. Titanium offers superior corrosion resistance and is the recommended choice if you are using aggressive cooling fluids like seawater or water with high chloride ion concentrations, which can cause pitting or crevice corrosion in stainless steel.

Can I use your spare parts on my Alfa Laval or Sondex heat exchanger?

Yes. Heating Formula provides high-quality spare parts, including plates and gaskets, that are fully compatible with and equivalent to those from major OEM brands like Alfa Laval, Sondex, APV SPX, Funke, and Tranter. Our parts offer a reliable and cost-effective alternative for your maintenance needs without compromising on performance.