The Unsung Hero of Alumite Treatment: How Heat Exchangers Perfect Your Finish

In the world of metal finishing, precision isn’t just a goal; it’s a requirement. For aluminum parts, achieving that perfect blend of durability, corrosion resistance, and aesthetic appeal often comes down to a process known as alumite treatment, or anodizing. This sophisticated electrochemical process is the secret behind the robust, colorful finishes on everything from smartphone casings to architectural panels and automotive components.

While the science of electrolysis gets most of the credit, there’s an unsung hero working tirelessly behind the scenes: the heat exchanger. The concept of transferring heat between two fluids to control process temperatures has been around since the late 19th century, evolving from simple tube-in-tube designs to the high-efficiency units we see today. In modern alumite treatment, this technology is not just helpful—it’s absolutely critical. Without precise temperature control, the entire anodizing process can fail, leading to costly defects and inconsistent quality.

This post will dive into the crucial role of bath solution heaters and coolers in alumite lines and explain how selecting the right heat exchanger can make all the difference in achieving a flawless, durable finish.

What is Alumite Treatment and Why is Temperature So Critical?

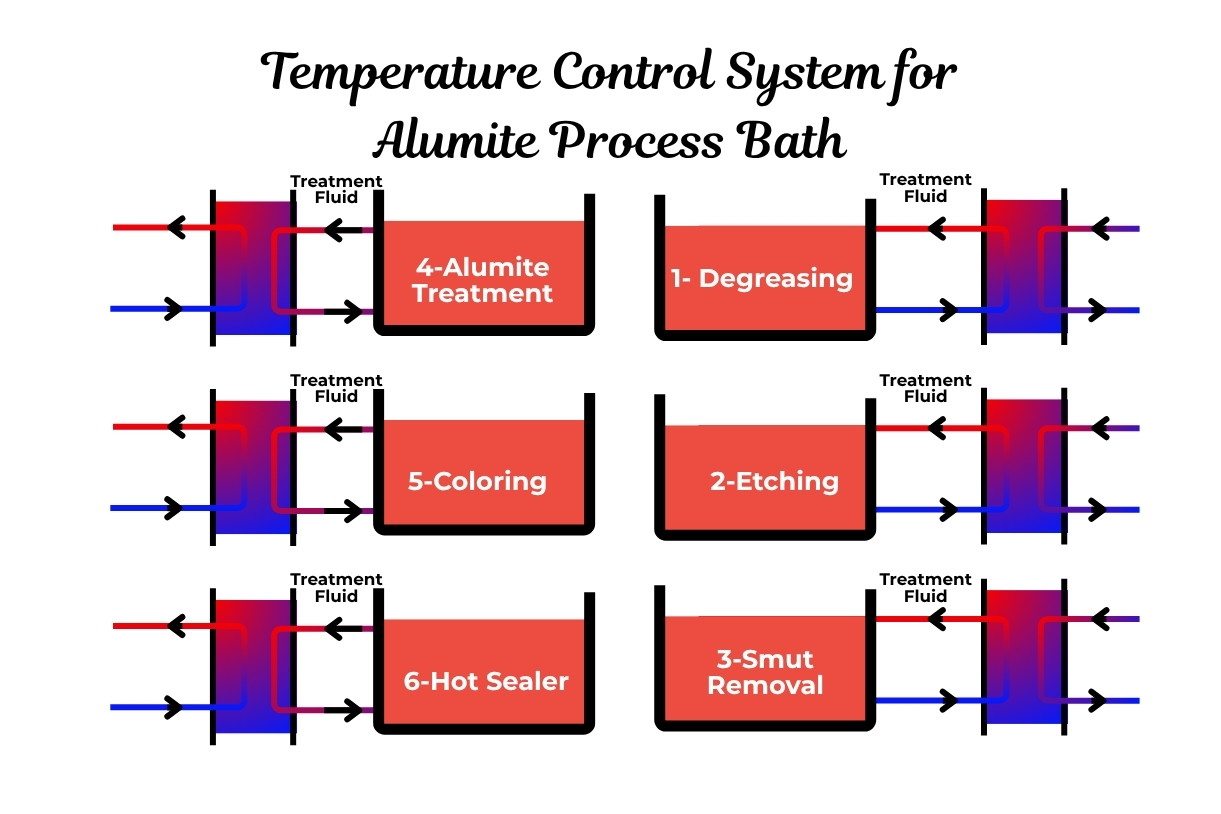

Alumite treatment, or aluminum anodizing, is an electrochemical process that creates a thick, stable oxide layer on the surface of an aluminum part. This layer is an integral part of the metal, making it far more durable and corrosion-resistant than the raw aluminum itself. The process involves several stages, each requiring a specific chemical bath and, most importantly, a specific temperature:

- Degreasing and Cleaning: Removes oils and contaminants from the surface.

- Etching: Creates a matte, satin finish by removing a thin layer of aluminum.

- Anodizing: The core of the process, where the part is submerged in an electrolyte bath (commonly sulfuric acid) and an electric current is passed through it. This builds the anodic oxide layer.

- Coloring (Optional): Dyes are absorbed into the porous oxide layer.

- Sealing: The final step, which closes the pores of the oxide layer to lock in color and maximize corrosion resistance.

Temperature control at each stage is non-negotiable. For example, during the main anodizing step, the temperature of the sulfuric acid bath directly influences the properties of the oxide layer. If the temperature is too high, the oxide layer can become soft, porous, and less resistant to abrasion. If it’s too low, the process slows down, impacting productivity. Consistent temperature ensures that every part, from the first to the last, has the same thickness, hardness, color uniformity, and protective qualities.

How Do Heat Exchangers Work in Anodizing Lines?

Heat exchangers are the workhorses that maintain the precise temperatures needed in each chemical bath. They function by either heating or cooling the solutions as required. The anodizing process itself generates heat, which must be removed continuously to keep the bath at its optimal temperature. In colder climates or during startup, other baths may need to be heated.

Two main types of heat exchangers are commonly used in these applications:

- Gasketed Plate Heat Exchangers (GPHEs): These are often the preferred choice due to their high thermal efficiency and compact footprint. As discussed in our post on the benefits of GPHEs, their design promotes high turbulence, which enhances heat transfer and helps reduce fouling. GPHEs are also highly flexible; they can be easily opened for cleaning and inspection, a crucial advantage when dealing with the aggressive chemicals in alumite lines.

- Shell and Tube Heat Exchangers: Known for their ruggedness, shell and tube exchangers can handle very high pressures and temperatures. They are a reliable choice for less-critical heating duties or in plants where robustness is the primary concern.

The key to their effectiveness lies in what engineers call thermal performance—the ability to transfer heat efficiently with minimal energy loss. By using a well-designed heat exchanger, anodizing facilities can achieve stable bath temperatures, leading to a more consistent and higher-quality final product.

What are the Biggest Challenges in Heating and Cooling Alumite Baths?

Managing the thermal profile of anodizing lines is not without its challenges. The operating environment is harsh, and several factors can impact performance and operational costs:

- Aggressive Corrosion: The electrolyte baths, especially those using sulfuric acid, are extremely corrosive to many metals. This constant chemical attack can quickly destroy improperly selected equipment, leading to leaks, contamination, and costly downtime.

- Fouling and Scaling: As detailed in our overview of fouling mechanisms, the precipitation of chemical salts and mineral scale on heat transfer surfaces is a major issue. Fouling acts as an insulating layer, drastically reducing the heat exchanger’s efficiency and forcing pumps to work harder to overcome the increased pressure drop.

- High Energy Costs: Maintaining dozens of large chemical tanks at precise temperatures around the clock is an energy-intensive operation. Inefficient heat transfer leads to wasted energy, which, as noted in our analysis of hidden costs, directly impacts the bottom line.

Choosing the right heat exchanger, particularly one made from the correct materials, is the first and most important step in overcoming these challenges.

Which Heat Exchanger Materials are Best for Corrosive Anodizing Solutions?

Material selection is a classic case of balancing budget and performance. While it might be tempting to opt for a lower-cost material, the corrosive nature of alumite baths means that suitability is king. Using the wrong material can lead to catastrophic failure.

Here’s a breakdown of common materials and their use in anodizing lines:

- Stainless Steel (316/304): While excellent for many industrial applications, standard stainless steel grades are generally not suitable for direct contact with the primary sulfuric acid anodizing bath. They will corrode quickly. However, they can be a cost-effective option for less aggressive pre-treatment, rinsing, or de-smutting stages.

- Titanium: This is often the material of choice for the main anodizing tanks. Titanium offers exceptional resistance to corrosion from sulfuric acid and many other chemicals used in the process, ensuring a long and reliable service life.

- Special Alloys (C-276 Hastelloy, 254 SMO): For the most aggressive environments, such as those with high chloride concentrations or specific chemical mixtures, advanced alloys are required. Materials like C-276 Hastelloy and 254 SMO provide superior resistance and ensure operational integrity where other materials would fail.

At Heating Formula, we provide a wide range of GPHE spare parts including plates and gaskets crafted from these specialized materials. Whether you need Titanium plates for your main bath or robust EPDM gaskets, our parts are manufactured to meet or exceed OEM standards, offering compatible replacements for brands like Alfa Laval, Sondex, and APV SPX.

How Can You Optimize Heat Exchanger Performance and Reduce Costs?

Beyond selecting the right material, there are several ways to optimize your heat exchanger’s performance and minimize operational costs:

- Ensure Proper Sizing: As highlighted in our guide to sizing a plate heat exchanger, a unit that is too large or too small for its task will be inefficient. An oversized unit results in unnecessary capital expenditure, while an undersized unit will fail to meet thermal demands, leading to poor product quality. For an initial assessment of your needs, our Heat Exchanger Calculator can provide a useful starting point.

- Implement a Proactive Maintenance Schedule: Regular cleaning and inspection are vital to prevent fouling from crippling your system’s efficiency. Monitoring the pressure drop across the heat exchanger is a simple yet effective way to know when cleaning is needed. This proactive approach, a key theme in our post on preventing bottlenecks, avoids costly emergency shutdowns and extends the equipment’s lifespan.

- Partner with a Reliable Supplier: Working with an expert supplier like Heating Formula ensures you receive not just a product, but a solution. We understand the complexities of alumite treatment and can help you select the right heat exchanger and materials for your specific process, ensuring long-term performance and reliability.

Perfect Your Process with Heating Formula

Achieving a flawless alumite finish demands precision, and that precision begins with outstanding temperature control. A robust, efficient, and chemically resistant heat exchanger is not an expense—it’s an investment in product quality, operational stability, and your bottom line.

As a leading Turkish manufacturer, Heating Formula specializes in providing high-quality thermal solutions for the most demanding industrial applications. We offer a comprehensive range of Gasketed Plate Heat Exchangers (GPHEs) and Shell & Tube exchangers designed for reliability and performance. Furthermore, we supply a wide inventory of compatible spare parts, including plates made from 316/304 Stainless Steel, Titanium, C-276 Hastelloy, and 254 SMO, as well as durable EPDM, NBR, and Viton gaskets. Our components are fully compatible with major OEM brands, including Alfa Laval, Sondex, APV SPX, Funke, Schmidt, Vicarb, Gea, and Tranter, giving you a trusted and cost-effective source for all your maintenance needs.

Contact Heating Formula today to discover how our heat exchangers can elevate your alumite treatment process.

Frequently Asked Questions (FAQ)

Q: Why is titanium a common choice for heat exchangers in anodizing?

A: Titanium is highly resistant to corrosion from sulfuric acid, which is the most common electrolyte used in alumite (anodizing) baths. This resistance prevents the heat exchanger from degrading and contaminating the bath, ensuring a long service life and consistent product quality.

Q: Can I use a standard stainless steel heat exchanger for an alumite bath?

A: It is not recommended for the main anodizing tank. Standard stainless steel grades, even 316, will corrode in the presence of sulfuric acid, especially at operating temperatures. This can lead to leaks and process contamination. However, stainless steel may be suitable for less aggressive pre-treatment or post-treatment rinsing stages.

Q: How often should I clean my heat exchanger in an alumite line?

A: The cleaning frequency depends on the rate of fouling, which is influenced by your specific process chemistry and operating conditions. The best practice is to monitor the pressure drop across the heat exchanger and its thermal performance. A significant increase in pressure drop or a decrease in performance indicates that cleaning is necessary to prevent bottlenecks and maintain efficiency.

Q: What’s the difference between a GPHE and a Shell & Tube exchanger for this application?

A: Gasketed Plate Heat Exchangers (GPHEs) generally offer higher thermal efficiency, a more compact design, and are much easier to open for cleaning and maintenance—a significant advantage in applications prone to fouling. Shell & Tube exchangers are extremely robust and are typically used for very high-pressure or high-temperature duties where their rugged construction is beneficial. For most alumite bath applications, a GPHE is the more efficient choice. Explore our GPHE Selection page to learn more.

Q: How can I calculate the heating or cooling load required for my anodizing tank?

A: Calculating the precise thermal load involves several factors, including the volume of the tank, the type of chemical solution, the required temperature change, the heat generated by the process, and the time for each cycle. For a quick and reliable initial estimate, you can use our online Heat Exchanger Calculator. For a detailed analysis, it’s always best to consult with a thermal engineering expert.