The Ultimate Guide to Industrial Heat Exchangers: How They Work and Why They Matter

In the engine room of modern industry, from sprawling power plants to meticulous food and beverage facilities, an unsung hero works tirelessly behind the scenes: the heat exchanger. You don’t need to be a thermal engineer to know what it does, but if you’re responsible for running industrial systems, optimizing production, or managing operational budgets, you absolutely need to understand what the right one can do for you.

These devices are the heart of thermal management, critical for everything from pasteurizing milk to cooling critical equipment in automotive manufacturing. As a leading Turkish manufacturer and supplier of high-performance plate heat exchangers and compatible spare parts, Heating Formula has seen firsthand how the right thermal solution can transform an operation’s efficiency and bottom line.

This guide will break down how heat exchangers work, explore the different types available, and explain why selecting and maintaining the right unit is mission-critical for industries across the board.

A Brief History of Heat Transfer

The concept of transferring heat isn’t new. For centuries, humans have used basic principles to warm their homes and cook their food. However, the industrial-grade heat exchanger as we know it began to take shape during the 19th century, driven by the demands of the Industrial Revolution and the rise of the steam engine. The first designs were simple, often a “pipe-in-pipe” setup, but they laid the foundation for the sophisticated technology we see today.

Major innovations, like the development of the first commercially viable plate heat exchanger in the 1920s, revolutionized the field. This shift from bulky shell-and-tube models to compact, efficient plate designs unlocked new possibilities for countless sectors. Japan, for instance, saw its first domestically-produced plate heat exchanger in 1953, marking a global expansion of this crucial technology1. Today, manufacturers like Heating Formula continue this legacy of innovation, producing a vast range of models to meet ever-more sophisticated industrial needs.

How Do Heat Exchangers Actually Work?

At its core, a heat exchanger follows a simple but powerful principle of thermodynamics: it transfers thermal energy from one fluid (a liquid or gas) to another without the two fluids ever mixing. If you want to dive deeper into the science, you can learn more about what exactly is a heat exchanger and why it matters so much.

In a typical plate heat exchanger, this is achieved through a series of thin, corrugated metal plates. These plates are pressed together, creating intricate channels for the fluids to flow.

- The Setup: A series of metal plates, often made of stainless steel or more exotic materials like titanium, are stacked together. Each plate is fitted with a gasket, which seals the channels and guides the flow.

- The Flow: The hot fluid and the cold fluid flow through alternating channels. The corrugated pattern on the plates creates turbulence, which dramatically increases the efficiency of heat transfer.

- The Transfer: As the hot fluid flows down one side of a plate, the cold fluid flows up the other. The heat passes through the thin plate material—from the hot side to the cold side—but the gaskets ensure the fluids themselves remain separate. This process is governed by the overall heat transfer coefficient (U-value), a key metric of performance.

The result is a highly efficient, compact, and scalable method for heating, cooling, condensing, or evaporating fluids, making it indispensable across dozens of industries.

What Are the Different Types of Industrial Heat Exchangers?

While the core principle is consistent, heat exchangers come in several designs, each tailored for specific industrial applications. Choosing the right one is critical for performance, maintenance, and cost-effectiveness. Here’s a look at the most common types.

Gasketed Plate Heat Exchangers (GPHEs)

This is the workhorse of modern industry. GPHEs are modular units prized for their flexibility and high thermal efficiency. Because they can be easily opened by loosening the tightening bolts, they are simple to clean, inspect, and maintain—a huge advantage in industries where fouling or regular servicing is a concern.

- Best For: HVAC, chemical processing, food and beverage, and marine applications where operational uptime and easy maintenance are paramount.

- Heating Formula Solution: Our GPHE Selection offers a wide range of customizable options. As a leading supplier, we also provide high-quality GPHE Spare Parts compatible with major OEM brands like Alfa Laval, Sondex, APV SPX, Funke, Schmidt, Vicarb, Gea, and Tranter, ensuring your operations keep running smoothly.

Brazed Plate Heat Exchangers (BPHEs)

Instead of gaskets, BPHEs use brazing material, typically copper or nickel, to fuse the stainless steel plates together. This creates an incredibly compact, leak-proof, and durable unit. BPHEs are excellent for high-pressure and high-temperature applications where regular disassembly isn’t required.

- Best For: Refrigeration, industrial water heaters, hydraulic oil cooling, and HVAC systems where a compact, low-maintenance solution is needed.

Welded Plate Heat Exchangers

For the most extreme industrial environments, welded heat exchangers offer maximum durability. These units can be semi-welded or fully-welded.

Semi-welded models use welded “cassettes” for one fluid circuit (typically the aggressive one) and gaskets for the other, offering a balance of safety and serviceability.

Fully welded units are completely sealed and gasket-free, making them ideal for handling aggressive fluids and extreme pressures and temperatures.

- Best For: Oil & Gas, petrochemicals, refineries, and applications involving aggressive media like ammonia or sulfuric acid.

Shell and Tube Heat Exchangers

The traditional heavyweight, shell-and-tube exchangers consist of a bundle of tubes housed within a large cylindrical shell. One fluid runs through the tubes while the other flows over them in the shell. They are incredibly robust and can handle very high pressures and temperatures, though they are much larger and less thermally efficient than modern plate designs.

- Best For: Power plants, oil refineries, and large-scale chemical processing where rugged reliability is the top priority.

Why Is Proper Heat Exchanger Sizing So Crucial?

One of the most common—and costly—mistakes in thermal management is improper heat exchanger sizing. It’s not just about fitting a unit into your available space; it’s about precisely matching the equipment to your process’s thermal and hydraulic demands. For a more detailed walkthrough, see our guide on the essential steps for accurately sizing a plate heat exchanger.

- An undersized unit will fail to meet your heating or cooling targets, creating a production bottleneck that slows down your entire operation.

- An oversized unit is not only more expensive upfront but also leads to wasted energy, potential control issues, and a higher total cost of ownership.

Achieving the right size ensures optimal performance, minimizes energy consumption, and extends the unit’s service life. To help engineers and purchasers avoid these pitfalls, Heating Formula offers a free

Heat Exchanger Calculator. This tool allows you to input your flow rates, temperatures, and media types to get an accurate sizing recommendation, ensuring you get the perfect fit for your application.

Which Materials Are Best for Corrosive Applications?

Material selection is another critical decision, especially when dealing with aggressive or corrosive fluids like seawater, acids, or certain chemicals.While stainless steel (e.g., 304, 316) is a common standard, demanding applications require more robust materials.

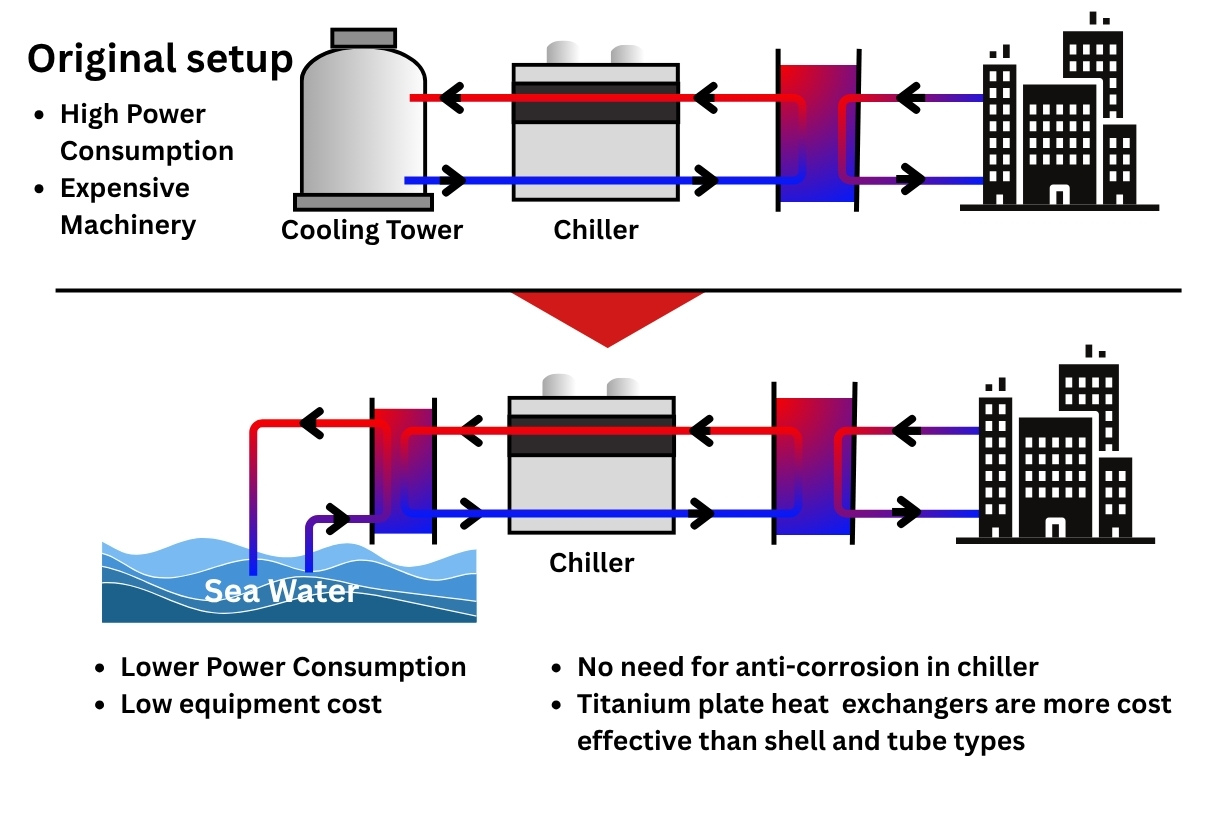

- Titanium in Heat Exchangers: Titanium is exceptionally resistant to corrosion from chlorides, making it the ideal choice for seawater cooling, chemical processing, and marine applications. Its strength and longevity justify the investment in harsh environments.

- Why 254 SMO Is the Champion for Corrosive Applications: 254 SMO is a high-alloy austenitic stainless steel designed for maximum resistance to pitting and crevice corrosion. It excels in handling halide-containing environments like chlorinated seawater and acidic process fluids.

Choosing the correct material from the start prevents premature failure, costly downtime, and potential safety hazards. Before you make a decision, it’s always wise to review an industrial heat exchangers – buyer’s guide.

FAQ: Your Heat Exchanger Questions Answered

Q: How can I size a plate heat exchanger correctly?

A: Accurate sizing depends on your flow rates, inlet/outlet temperatures, fluid types, and allowable pressure drop. For a precise calculation tailored to your specific needs, use our Heat Exchanger Calculator or consult with one of our thermal engineering experts.

Q: What is the difference between a gasketed and a brazed plate heat exchanger?

A: Gasketed plate heat exchangers (GPHEs) use gaskets to seal the plates and can be disassembled for cleaning and maintenance, making them ideal for processes with fouling risk. Brazed plate heat exchangers (BPHEs) are permanently sealed with brazing material, offering a more compact and leak-proof design suitable for high-pressure applications like refrigeration where regular cleaning isn’t needed.

Q: How often do the gaskets on a GPHE need to be replaced?

A: Gasket life depends on operating temperatures, pressures, and the type of fluid being processed. For temperatures around 100°C, a replacement guideline is every 1-3 years. Regular inspection is key to preventing leaks and ensuring performance. If you need replacements, Heating Formula provides a wide range of

Q: My plant uses several heat exchanger brands. Can I get compatible spare parts from a single supplier?

A: Absolutely. This is where Heating Formula excels. We manufacture and supply high-quality compatible spare parts for all major OEM brands, including Alfa Laval, Sondex, APV SPX, Funke, Schmidt, Vicarb, Gea, and Tranter. Partnering with a multi-brand service provider simplifies your maintenance, streamlines sourcing, and reduces costs.

Q: How do modern plate designs improve energy savings?

A: Advanced plate designs, like the Fishbone pattern, are engineered to maximize turbulence even at low flow rates30. This enhances the overall heat transfer coefficient, allowing you to achieve the same thermal duty with fewer plates and a smaller unit. This improved efficiency is a key reason

why plate heat exchangers save energy for our industry.

Sources

- U.S. Department of Energy. (n.d.). Heat Exchangers. Energy.gov. Retrieved from https://www.energy.gov/eere/amo/heat-exchangers

- Stehlík, P., & Wadekar, V. V. (2002). Different Strategies to Improve Industrial Heat Exchange. Heat Transfer Engineering, 23(6), 36–48. 31

- The Engineering Toolbox. (n.d.). Overall Heat Transfer Coefficients. Retrieved from https://www.engineeringtoolbox.com/overall-heat-transfer-coefficient-d_434.html