Efficient H₂S Removal: The Pivotal Role of Heat Exchangers in Gas Treating Units

Heat exchangers are indispensable components within gas treating units, particularly in processes focused on sulfur recovery. These critical pieces of equipment facilitate the efficient removal of acidic gases, primarily hydrogen sulfide (H₂S), ensuring operational integrity and environmental compliance. As a leading plate heat exchanger manufacturer and supplier based in Turkey, Heating Formula provides high-quality heat exchangers and compatible spare parts for a wide range of industrial applications, including those vital for efficient gas treatment. Our products offer OEM compatibility with major brands like Alfa Laval, Sondex, APV SPX, Funke, Schmidt, and Tranter, ensuring seamless integration and reliable performance.

The Role of Heat Exchangers in Sulfur Recovery Processes

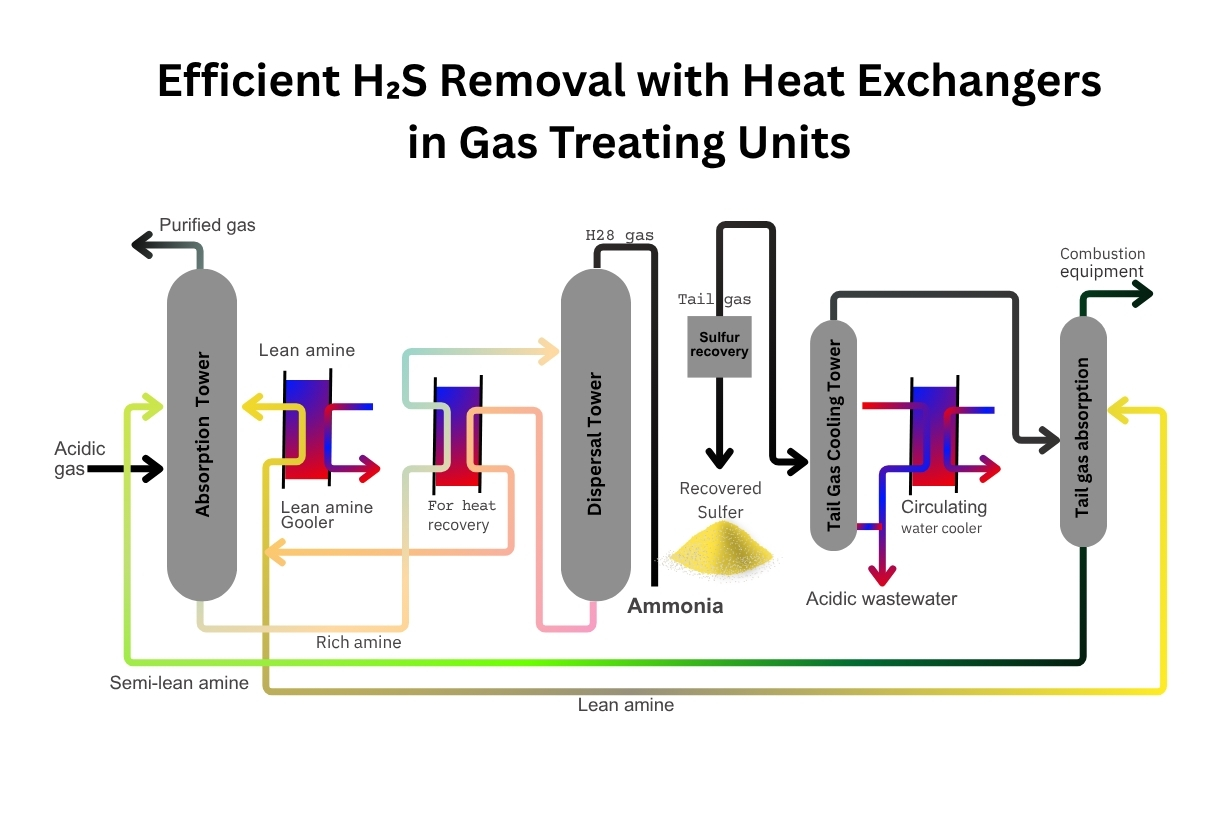

Sulfur recovery processes are crucial in industries such as oil and gas, and chemical manufacturing. They typically involve treating sour gas (natural gas or refinery gas containing H₂S) and tail gas with amine solutions. Heat exchangers play a vital role in optimizing the performance of these processes by controlling critical temperature points for efficient H₂S absorption and regeneration.

Within a typical sulfur recovery unit, such as the Claus process, heat exchangers are strategically placed to manage energy transfer. They ensure that the amine solution effectively absorbs H₂S from the sour gas and then efficiently releases it for sulfur conversion. This precise temperature control is paramount for maximizing H₂S removal efficiency and minimizing energy consumption.

For a deeper understanding of how these systems impact overall plant efficiency, you might want to read our article on Why Plate Heat Exchangers Save Energy for Our Industry.

Why Are Heat Exchangers So Crucial for H₂S Removal?

The efficiency of H₂S removal hinges on precise thermal management. Here’s why heat exchangers are indispensable in gas treating units:

- Temperature Control for Amine Performance: Amine solutions, commonly used for H₂S absorption, have optimal operating temperature ranges. If the temperature is too high, the amine can degrade, leading to reduced absorption capacity. If it’s too low, the viscosity of the amine increases, affecting flow and contact efficiency. Heat exchangers preheat the lean amine before it enters the absorber and cool the rich amine before regeneration, maintaining ideal conditions throughout the cycle.

- Energy Recovery and Efficiency: Gas treating processes are energy-intensive. Heat exchangers enable significant energy recovery by utilizing the heat from hot process streams to preheat cooler streams. This reduces the overall energy demand of the unit, contributing to lower operational costs and a smaller carbon footprint. Discover more about improving thermal performance in our article on Understanding the Overall Heat Transfer Coefficient (U-Value).

- Preventing Fouling and Corrosion: H₂S can be corrosive, and process streams often contain impurities that can lead to fouling. Selecting the right heat exchanger materials, such as titanium plates for corrosive environments, and employing designs that promote turbulent flow helps mitigate these issues, extending equipment lifespan and reducing maintenance needs. Learn about specific material advantages in Titanium in Heat Exchangers and Why 254 SMO Is the Heat Exchanger’s Champion for Corrosive Applications.

- Optimized Process Conditions: By allowing for precise temperature control, heat exchangers ensure that chemical reactions occur at their most efficient rates, leading to maximum H₂S removal and higher purity sulfur products. This is especially important in the tail gas treating unit, where residual sulfur compounds are further processed.

Types of Heat Exchangers Used in Gas Treating Units

While various heat exchanger types can be found in gas treating facilities, plate heat exchangers are increasingly favored for their efficiency and adaptability:

- Gasketed Plate Heat Exchangers (GPHEs): These are highly versatile due to their modular design, allowing for easy cleaning, inspection, and capacity adjustments. They are commonly used in various stages of gas treating, including lean/rich amine heat exchange, cooling of lean amine, and reboiler duties. Their high heat transfer coefficients and compact footprint make them a preferred choice for maximizing efficiency in limited spaces.

- Welded Plate Heat Exchangers (WPHEs): For more aggressive fluids or higher temperature and pressure applications within the sulfur recovery process, welded plate heat exchangers offer robust, gasket-free solutions. They are particularly suitable for duties involving corrosive streams or situations where leakage cannot be tolerated.

- Shell and Tube Heat Exchangers: Traditionally, shell and tube heat exchangers have been widely used in oil and gas and chemical processing due to their robust design and ability to handle high pressures and temperatures. However, they typically require more space and offer lower thermal efficiency compared to plate heat exchangers.

When considering new equipment, it’s essential to understand the advantages and limitations of each type. Our Industrial Heat Exchangers – Buyer’s Guide offers comprehensive insights.

Maintaining Optimal Performance: Preventing Fouling

Fouling, the accumulation of unwanted deposits on heat transfer surfaces, is a persistent challenge in gas treating units, especially when handling process streams containing impurities like elemental sulfur, corrosion products (e.g., iron sulfide), or dissolved solids1111. Fouling can significantly reduce a heat exchanger’s thermal performance, increase pressure drop, and lead to higher energy consumption and more frequent shutdowns for cleaning222222222.

Common fouling mechanisms in sulfur recovery units include:

- Precipitated Salts: Carbonate and sulfate scales, which become less soluble with temperature changes, can deposit on hot surfaces3333.

- Suspended Solids: Particles like sand, silts, and clays can accumulate, potentially accelerating other fouling types by acting as nucleation sites4.

- Organic Fouling: Precipitation of organic materials due to solubility changes can occur5.

- Corrosion Fouling: Reaction between the heat exchanger material and fluids can form corrosion products that impede heat transfer6.

To combat fouling, strategies such as regular chemical cleaning (CIP – Cleaning-in-Place) and mechanical cleaning are employed. Chemical treatments dissolve and remove deposits, while mechanical methods physically dislodge them. For optimal long-term operation, proactive measures, including proper material selection and periodic maintenance, are crucial.

You can find more detailed information on preventing these issues in our guide on What Should You Know Before You Buy a Heat Exchanger?.

Heating Formula: Your Partner in Efficient Gas Treating

At Heating Formula, we are committed to providing top-tier plate heat exchangers and spare parts that ensure the efficient and reliable operation of your gas treating units. Our products are designed to meet the rigorous demands of industries dealing with H₂S removal, offering:

- Tailored Solutions: Our extensive range of GPHEs and specialized plates can be configured to precisely match your thermal requirements, maximizing efficiency and minimizing operational costs.

- High-Quality Materials: We offer plates in various corrosion-resistant materials, including stainless steel and titanium (TP270, TP270-Pd), and high nickel alloys like C-276 and C-229, to withstand the challenging conditions of H₂S-laden streams.

- OEM Compatibility: Our spare parts are compatible with a wide array of existing heat exchanger installations, ensuring seamless replacements and reduced downtime.

- Expert Support: We provide comprehensive service and support, from selection assistance using our Heat Exchanger Calculator to supplying genuine GPHE Spare Parts and guiding you through maintenance best practices.

By choosing Heating Formula, you partner with a manufacturer dedicated to optimizing your processes, enhancing operational longevity, and contributing to a cleaner, more sustainable industrial future. Explore our full range of solutions for GPHE Selection to find the perfect fit for your needs.

FAQ Section

Q: How do heat exchangers prevent fouling in gas treating applications?

A: Heat exchangers, particularly plate heat exchangers, are designed with plate patterns that promote high turbulence, which helps to prevent the accumulation of scale and other deposits on the heat transfer surfaces. Additionally, proper fluid velocity and regular cleaning methods like CIP (Clean-in-Place) further mitigate fouling. 10101010

Q: What materials are best for heat exchangers handling corrosive H₂S streams?

A: For corrosive H₂S streams, materials with high corrosion resistance are essential. Stainless steels (like SUS316L and 254 SMO) and titanium (TP270, TP270-Pd), and high nickel alloys (like Hastelloy C-276 and C-22) are commonly recommended due to their superior resistance to various corrosive agents encountered in gas treating units.

Q: How does proper heat exchanger sizing impact H₂S removal efficiency?

A: Proper sizing ensures that the heat exchanger can achieve the required heat transfer duties with optimal temperature differentials and minimal pressure drops. An undersized unit will fail to meet process demands, while an oversized one can lead to unnecessary capital and operational costs. Accurate sizing directly impacts the efficiency of H₂S absorption and regeneration, contributing to overall system performance. Use our Heat Exchanger Calculator for precise sizing.

Q: What is the benefit of using plate heat exchangers over shell and tube exchangers for gas treating?

A: Plate heat exchangers offer several advantages, including higher thermal efficiency, a more compact footprint, and easier maintenance due to their demountable design. They also provide better resistance to fouling due to turbulent flow patterns. This leads to lower operational costs, reduced downtime, and greater flexibility for capacity adjustments compared to traditional shell and tube units.

Q: How often should heat exchangers in gas treating units be maintained?

A: The maintenance frequency depends on operating conditions, fluid characteristics, and the extent of fouling. Regular monitoring of performance parameters, such as pressure drop and thermal efficiency, helps determine the optimal maintenance schedule. Typically, new units are inspected annually to establish an appropriate cycle, with chemical or mechanical cleaning performed as needed.

Sources

- [1] Jalili, B., Aghaee, N., Jalili, P., & Ganji, D. D. (2022). Novel usage of the curved rectangular fin on the heat transfer of a double-pipe heat exchanger with a nanofluid. Case Studies in Thermal Engineering, 35, 102086. 14

- [2] Rooholamini, S., Ghorbani, B., & Ebrahimi, A. (2021). Introducing a novel hybrid system for cogeneration of liquefied natural gas and hot water using ejector-compression cascade refrigeration system (energy, exergy, pinch and sensitivity analyses). Applied Thermal Engineering, 196, 117283. 15

- [3] Engineering Page. (2025, March 19). Typical Overall Heat Transfer Coefficients (U-Values). 16