Overview

When selecting sealing materials for industrial, automotive, or chemical applications, it is critical to understand elastomer chemical compatibility. Using the wrong rubber can result in swelling, brittleness, or complete seal failure.

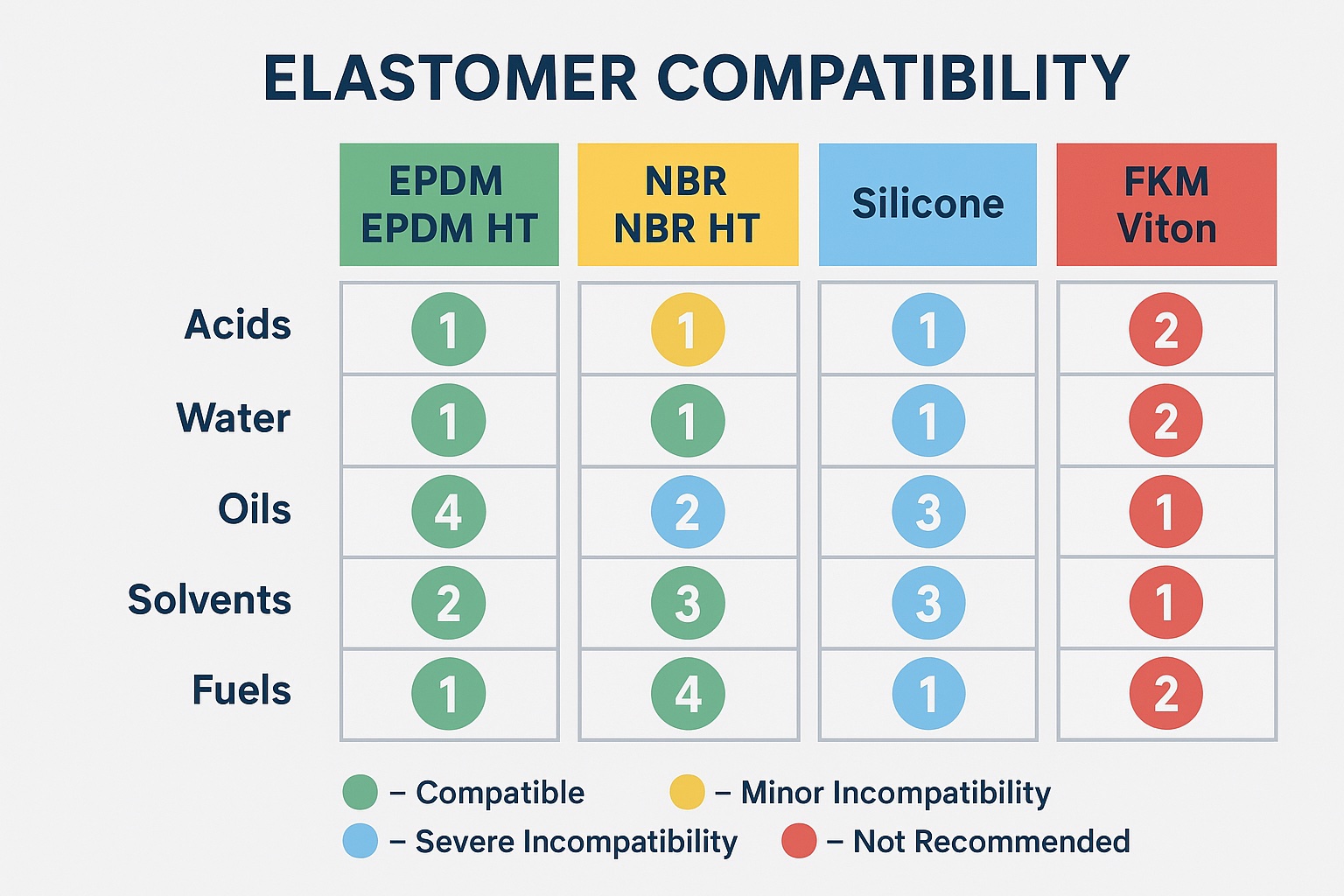

This guide summarizes compatibility ratings for six common elastomers:

- EPDM / EPDM HT

- NBR / NBR HT

- Silicone

- FKM (Viton)

Compatibility ratings are standardized as:

- 1 – Compatible

- 2 – Minor Incompatibility

- 3 – Severe Incompatibility

- 4 – Not Recommended

- 0 – Insufficient Data

Key Insights from the Compatibility Table

- EPDM / EPDM HT: Excellent resistance to acids, water, steam, and polar solvents, but not recommended for oils, fuels, and hydrocarbons.

- NBR / NBR HT: Strong resistance to oils, fuels, hydrocarbons, but poor against polar solvents and ozone.

- Silicone: Good performance in high and low temperatures, but weaker with fuels and strong acids.

- FKM (Viton): Superior chemical resistance overall, especially against oils, fuels, and aggressive chemicals, but can be more costly.

Frequently Asked Questions (FAQ)

Q1: What is the difference between EPDM and EPDM HT?

EPDM HT is a high-temperature grade of EPDM, offering better thermal stability. Chemical compatibility is essentially the same.

Q2: Is NBR HT the same as HNBR?

Not exactly. NBR HT can refer to high-temperature nitrile, but often HNBR (Hydrogenated NBR) is used for improved heat and ozone resistance. Compatibility is still very similar to standard NBR.

Q3: Which elastomer is best for fuel resistance?

NBR and FKM (Viton) perform best in hydrocarbon fuels and oils. EPDM should not be used for fuels.

Q4: Which elastomer is most versatile?

FKM (Viton) is generally the most chemically resistant, but EPDM is more economical for water and acid applications.

Q5: Can Silicone replace EPDM or NBR?

Not directly. Silicone is great for extreme temperatures but not always compatible with oils or fuels.