Is Your Marine Gas Oil (MGO) Cooler Really Working? A Deep Dive into a Small but Mighty Component

A ship moves forward not just on fuel, but on a thousand tiny, unseen efficiencies. We often focus on the grand machinery—the massive engines, the intricate navigation systems. But what about the unsung heroes? The components working silently in the background, making sure the whole system hums in harmony.

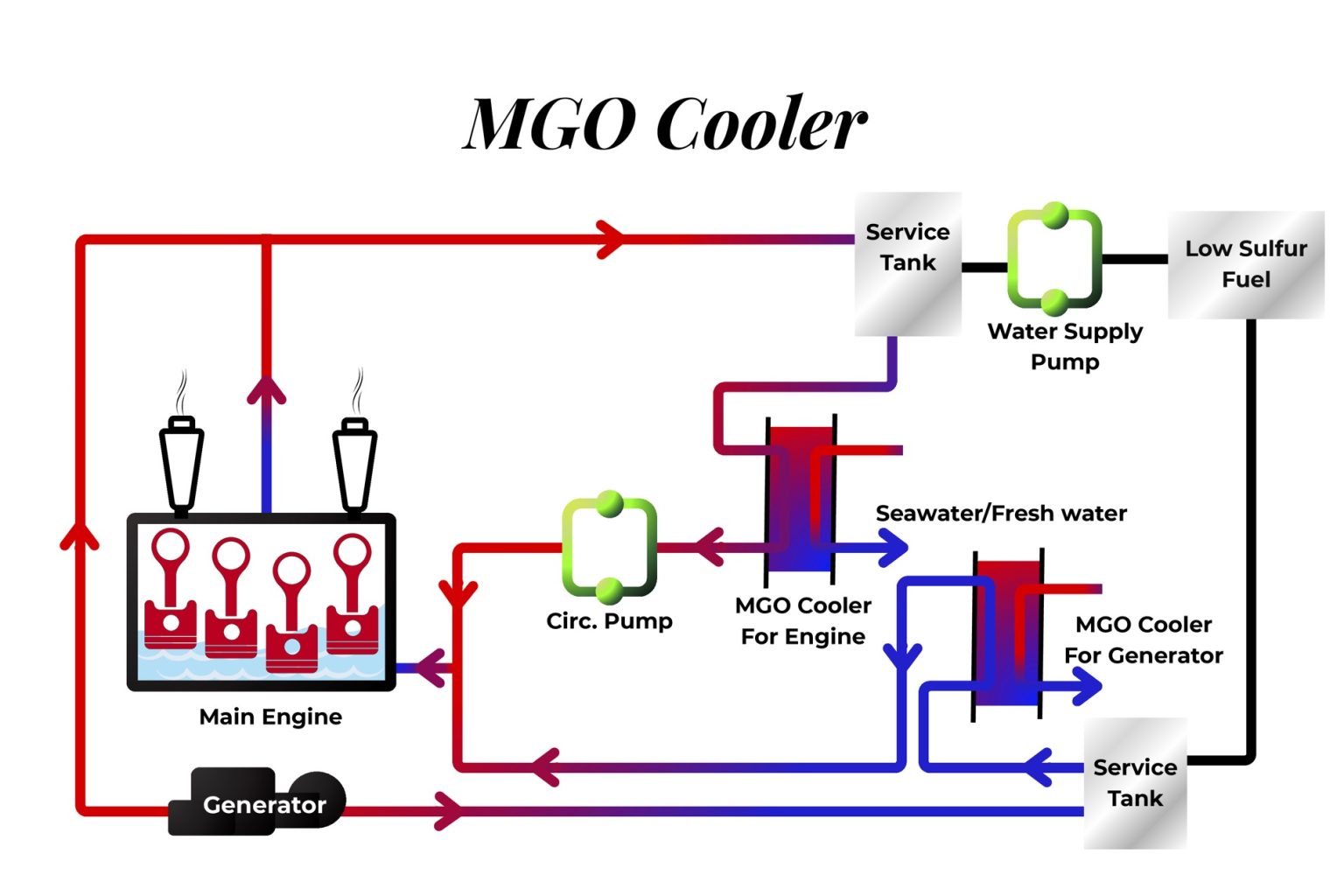

One of these is the MGO cooler. (Oil Cooler Heat Exchanger-MGO)

With strict new exhaust gas regulations in place, vessels are increasingly reliant on low-sulfur fuels like Marine Gas Oil (MGO). And while MGO is a cleaner alternative, it requires precise thermal management. This is where MGO coolers come in, reducing the fuel oil’s temperature to optimize engine performance and minimize the load. A small component, perhaps, but its failure can trigger a cascading domino effect of hidden costs, operational nightmares, and logistical headaches.

A recent story of a vessel in Brazil comes to mind. An LT cooler gasket, a part so small it’s easily overlooked, began to leak. Unnoticed during routine checks, this minor issue soon escalated. The leak cost over €7,000 in material losses alone, but that was just the beginning. The unplanned repair spiraled into a logistical nightmare: €20,000 for air-freighted parts, €15,000 for a fly-in technician, and another €5,000 for non-stop work schedules. The vessel’s journey was delayed, penalties mounted, and the total expense soared to nearly €50,000. All because of a single, neglected gasket.

This anecdote isn’t just a cautionary tale; it’s an urgent call to re-evaluate how we think about maintenance, efficiency, and the seemingly insignificant parts of a complex system. The real costs of neglect are rarely what they appear on the surface. They’re the “hidden ripples” that affect everything from fuel consumption and crew hours to missed deadlines and a compromised bottom line.

So, how can we move from a reactive model of crisis management to a proactive one of strategic foresight?

Are You Losing Money on Inefficient Performance?

The performance of your MGO cooler hinges on a delicate balance of thermal and hydraulic performance.

Thermal performance is about how effectively heat is transferred, while hydraulic performance ensures fluids move with minimal pressure drop1111. When these two are out of sync, your operation suffers.

On the thermal side, efficiency is defined by the overall heat transfer coefficient (

U), the heat transfer surface area (A), and the logarithmic mean temperature difference (LMTD). A high overall heat transfer coefficient, achieved through materials with good thermal conductivity and a design that promotes optimal fluid flow, is crucial. High turbulence and low fouling resistance are critical here.

On the hydraulic side, it’s all about smooth fluid dynamics. A well-designed system minimizes pressure drop, preventing the need for oversized pumps that consume more energy and space4444. When a heat exchanger becomes clogged or fouled, pressure drop increases, forcing pumps to work harder and wasting power.

What are the Common Culprits of MGO Cooler Failure?

Your MGO cooler’s performance can degrade for a variety of reasons, many of which are preventable.

1. Is Fouling the Hidden Cost Driver?

Fouling is the accumulation of unwanted substances on heat transfer surfaces, a primary cause of reduced efficiency and increased operating costs5. In a marine environment, this can be caused by marine organisms, algae, and sand in seawater, as well as sludge or particles in the oil itself6666.

- The Vicious Cycle: As fouling layers build up, the overall heat transfer coefficient decreases, necessitating more energy to maintain the required cooling duty. This creates a vicious cycle where a fouled heat exchanger requires more power to operate, increasing fuel consumption and operational costs.

- A Smarter Approach: Plate heat exchangers (PHEs), especially those with corrugated or herringbone patterns, are designed to create turbulent flow that actively works against fouling, extending cleaning intervals significantly compared to traditional shell-and-tube exchangers888888888. Choosing a PHE with a wider channel gap, often referred to as a “Free Flow” plate, can also handle media containing solids and fibers with less risk of clogging.

2. Are Your Gaskets Compromising Your System?

Gaskets are the primary sealing mechanism in a gasketed plate heat exchanger, and their failure is a leading cause of leaks10. As seen in our anecdote, an aging or incompatible gasket can lead to catastrophic failures.

- Age and Incompatibility: Over time, gaskets can harden, crack, or swell due to age, high temperatures, or exposure to aggressive fluids11111111. Choosing the correct gasket material—such as NBR, EPDM, or FPM—is critical for ensuring compatibility with both the process and utility fluids12.

- The

Double-SealSolution: Some modern heat exchangers feature adouble-sealdesign that prevents fluid intermixing. In the event of a gasket failure, the leaking fluid is directed outside the unit, making the problem immediately visible and preventing costly contamination13131313. This is a non-negotiable safety feature when one of the fluids is hazardous.

3. Is Thermal Fatigue Causing Cracks?

Operating with high pressures, fluctuating loads, and thermal stress can lead to fatigue cracking in the heat exchanger’s plates or welds. This is a particular risk for MGO coolers used in demanding applications14.

- Mitigation: This risk is a key driver for material selection and design. High-quality materials like titanium or certain stainless steels are essential for marine applications due to their corrosion resistance. Furthermore, modern plates with reinforced transition areas and robust construction are designed to withstand these stresses and ensure long-term reliability15.

A New Formula for Reliability: Proactive Maintenance & Smart Technology

The solution isn’t just about fixing problems when they arise. It’s about creating a system so resilient and transparent that major failures are a thing of the past.

- Embrace Predictive Maintenance: Instead of waiting for a gasket to fail, track its lifespan and replace it proactively. Services like

CIP (Cleaning-in-Place)can also extend the life of your heat exchanger by dissolving scale without disassembly16. - Leverage Digital Tools: Modern software can predict fouling rates, monitor performance degradation over time, and help you determine the optimal time to clean or service a unit17. This data-driven approach replaces guesswork with certainty.

- Partner with Experts: The complexities of modern heat exchanger design and maintenance demand expertise. Work with a supplier who acts as a true partner, offering a global network for spare parts and on-site support. This ensures that when an issue does occur, the solution is fast, efficient, and reliable.

By paying attention to the small details and embracing modern technology, you can turn a potential operational nightmare into a story of seamless efficiency. After all, the cost of an emergency repair is almost always more than the price of a little foresight.

References:

- Tranter Technical White Paper: “How advanced thermal hydraulics solve your process efficiency challenges.” (October 28, 2024).

- Alfa Laval Technical Paper: “In pursuit of long-term energy savings: Discovering lower total cost of ownership with more efficient heat exchangers.” (2024).

- HISAKA Works:

Manual and Application Guide for Plate Heat Exchangers.