Tapping into Earth’s Warmth: Geothermal Water Heating for Your Home with Plate Heat Exchangers

Imagine a future where your home’s hot water isn’t dependent on fluctuating energy prices or burning fossil fuels, but rather on the consistent, clean energy drawn directly from the earth beneath your feet. This isn’t a distant dream; it’s the growing reality of geothermal water heating, and at its heart often lies a remarkably efficient piece of technology: the plate heat exchanger.

The concept of harnessing the Earth’s internal heat isn’t new. For centuries, civilizations have utilized hot springs for bathing and rudimentary heating. Early geothermal applications involved simply directing hot water or steam from natural reservoirs to where it was needed. The large-scale harnessing of geothermal energy for power generation began in the early 20th century, with the first geothermal power plant established in Larderello, Italy, in 1904. Over time, as energy demands grew and environmental concerns mounted, the focus shifted towards more efficient and versatile ways to utilize this renewable resource for various applications, including residential heating. This evolution brought about advanced heat transfer technologies, such as the plate heat exchanger, which revolutionized how we can tap into this sustainable warmth.

What is Geothermal Energy, and How Does it Heat Your Water?

Geothermal energy originates from the heat within the Earth’s core, a continuous and immense source of warmth. This heat manifests in various ways, from shallow ground temperatures to hot underground water and steam reservoirs. For residential heating, shallow geothermal systems are commonly employed. These systems don’t require deep drilling into scalding hot zones; instead, they leverage the relatively constant temperature of the Earth a few feet below the surface. Below the frost line, the ground maintains a stable temperature, warmer than the air in winter and cooler than the air in summer.

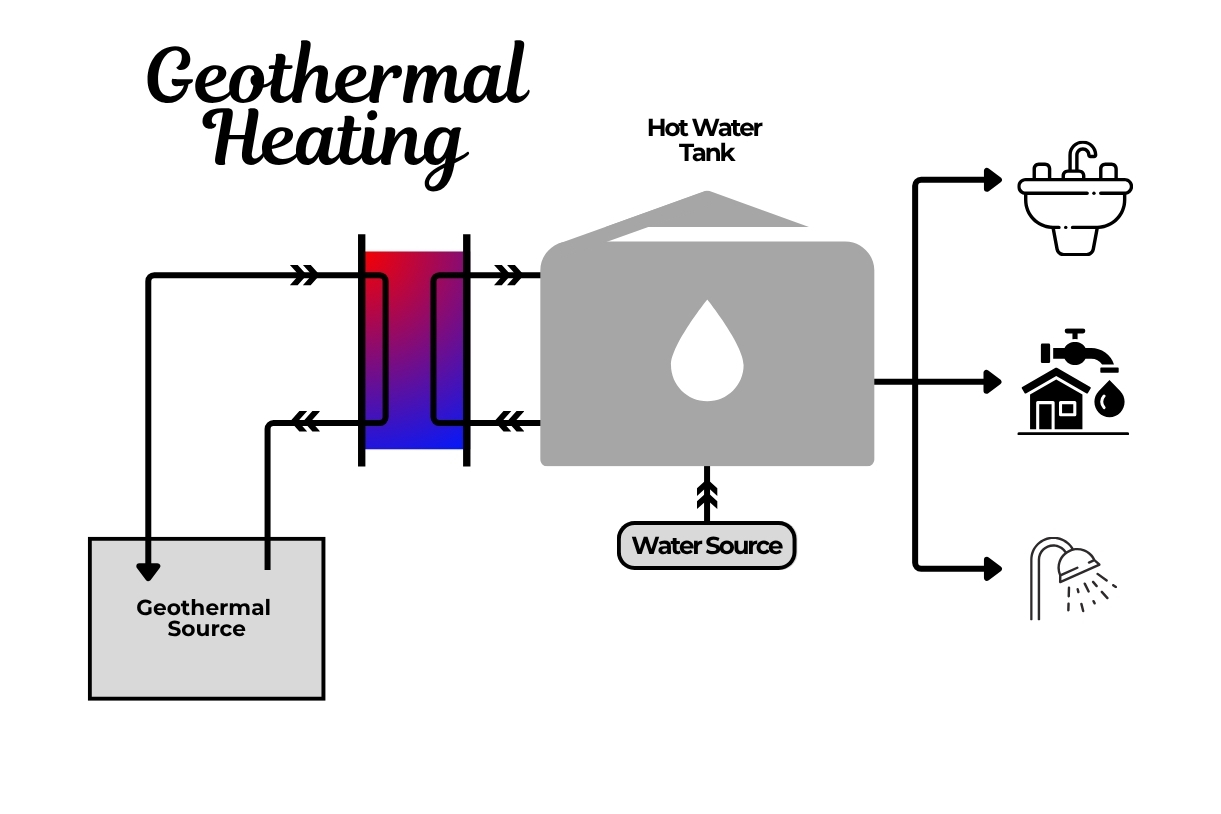

A geothermal water heating system typically works by circulating a fluid (often a water-antifreeze solution) through a loop of pipes buried underground, either horizontally in trenches or vertically in boreholes. This fluid absorbs the stable ground temperature. When the fluid returns to your home, it carries this absorbed heat. But how does this relatively low-temperature fluid efficiently heat your domestic water supply to comfortable levels? This is where the plate heat exchanger becomes the unsung hero of the system.

How Do Plate Heat Exchangers Efficiently Transfer Geothermal Heat?

Plate heat exchangers (PHEs) are designed for highly efficient heat transfer in a compact space, making them ideal for geothermal applications. Unlike traditional shell-and-tube heat exchangers, which transfer heat through tubes encased in a shell, PHEs utilize a series of thin, corrugated plates pressed together. These plates create narrow channels through which the hot and cold fluids flow in alternating patterns, separated by the thin metal plates.

The magic lies in several key design features:

- Large Surface Area in a Small Footprint: The corrugated design of the plates drastically increases the heat transfer surface area within a very compact volume. This means a smaller unit can handle significant heat loads, freeing up valuable space in your utility room.

- Turbulent Flow: The intricate patterns on the plates aren’t just for structural integrity; they induce high turbulence in the flowing fluids, even at low flow rates. This turbulence constantly mixes the fluid particles, ensuring that more of the fluid comes into direct contact with the heat transfer surface, leading to a much higher heat transfer coefficient compared to other heat exchanger designs.

- True Counter-Current Flow: In a well-designed plate heat exchanger, the hot and cold fluids flow in opposite directions through adjacent channels. This “counter-current” arrangement maximizes the temperature difference along the entire length of the heat exchanger, which is the driving force for heat transfer, leading to extremely efficient heat recovery. This means the geothermal fluid, even at a moderate temperature, can effectively preheat or fully heat your domestic water.

- Minimal “Dead Zones”: The intelligent design of plate patterns, including features like specialized distribution areas, prevents stagnant zones where fluid might sit without effectively transferring heat. This ensures that almost the entire plate surface contributes to heat transfer, maximizing efficiency.

In essence, the plate heat exchanger takes the relatively cool fluid from the geothermal loop, extracts its heat with remarkable efficiency, and transfers it to your potable water supply, delivering hot water on demand using minimal additional energy.

What Are the Different Types of Plate Heat Exchangers Used for Water Heating?

Several configurations of plate heat exchangers are employed for water heating, each suited to specific needs and conditions:

- Gasketed Plate Heat Exchangers (GPHEs): These are the most common type for residential and commercial geothermal applications. They feature plates separated by rubber gaskets that create a sealed environment. The modular design allows for easy disassembly for cleaning and maintenance, as well as the flexibility to add or remove plates to adjust heating capacity as demands change. This “openable” feature is a significant advantage, particularly in areas with water quality issues that might lead to fouling.

- Brazed Plate Heat Exchangers (BPHEs): In these units, the plates are permanently joined together by a brazing material (often copper or nickel) in a vacuum furnace, eliminating the need for gaskets. This creates an extremely compact and robust unit capable of handling higher pressures and temperatures than GPHEs. While not user-serviceable for internal cleaning, their durability and small size make them suitable for applications where a sealed system is preferred and the fluids are clean.

- Semi-Welded Plate Heat Exchangers: These are a hybrid, combining features of both gasketed and fully welded units. They use laser-welded plate cassettes for one fluid (typically the more aggressive or high-pressure fluid) and gaskets for the other, allowing for some degree of serviceability while providing enhanced pressure and temperature resistance. They offer a good balance between robustness and maintenance flexibility, often used in industrial refrigeration with ammonia.

Avoiding Common Mistakes in Geothermal Water Heating Systems

Implementing a geothermal water heating system with plate heat exchangers can be a significant investment, but avoiding common pitfalls ensures long-term efficiency and satisfaction.

- Improper Sizing of the Heat Exchanger: This is a critical mistake. An undersized unit won’t meet your hot water demands, while an oversized one is an unnecessary expense both in initial cost and operational inefficiencies. Accurate calculation of your home’s hot water needs, factoring in peak demand and recovery rates, is essential. Consulting with experienced professionals and utilizing advanced sizing tools is crucial.

- Neglecting Water Quality: The quality of your domestic water supply directly impacts the longevity and efficiency of the plate heat exchanger. Hard water, containing high mineral content, can lead to scaling on the heat transfer surfaces, reducing efficiency and increasing pressure drop over time. Regular water testing and appropriate pre-treatment (e.g., water softeners) can prevent these issues.

- Ignoring Fouling Management: Even with good water quality, some degree of fouling can occur. For gasketed plate heat exchangers, regular cleaning (either through Cleaning-in-Place (CIP) procedures or physical disassembly) is vital to maintain optimal performance. Chemical cleaning solutions specifically designed for heat exchangers can dissolve deposits without damaging the plates or gaskets. For units that are not easily disassembled (like brazed units), proper fluid filtration and CIP are paramount.

- Incorrect Installation and Maintenance Practices: Following the manufacturer’s instructions meticulously during installation and any subsequent maintenance is non-negotiable. Improper tightening of bolts on gasketed units, for instance, can lead to leaks and plate deformation. Proper training for operators and technicians is also key.

- Overlooking System Integration: A geothermal water heating system is more than just a heat exchanger. It involves ground loops, pumps, controls, and possibly a storage tank. Ensuring all these components are properly sized and integrated to work synergistically is vital for overall system efficiency and responsiveness.

Applications Beyond Homes: Where Else Do Plate Heat Exchangers Shine?

The versatility and efficiency of plate heat exchangers extend far beyond residential water heating. They are indispensable in numerous industries where precise thermal management is critical:

- HVAC Systems: From large commercial buildings to district heating and cooling networks, PHEs efficiently transfer heat for climate control, maximizing energy recovery and reducing losses.

- Food and Beverage Industry: Essential for pasteurization, sterilization, and temperature control of various liquids, including milk, juices, and brewing processes. Their hygienic design and ease of cleaning are crucial here.

- Chemical Processing: Handling a wide range of fluids, from aggressive chemicals to viscous substances, PHEs are used for heating, cooling, condensing, and heat recovery. Materials like titanium and Hastelloy are often employed for corrosive media.

- Marine and Offshore: Used for central cooling, lubrication oil cooling, and other thermal duties on vessels and platforms, often with specialized designs for seawater applications to prevent fouling.

- Power Generation: Vital for heat recovery, condensing steam, and cooling auxiliary systems in various power plants, including nuclear, gas, and coal-fired facilities.

- Heavy Industry: Found in metal production, mining, and other demanding environments for cooling hydraulic oil, tempering furnaces, and general process heating/cooling.

- Renewable Energy: Beyond geothermal, they are used in solar thermal systems and biomass energy production for efficient heat transfer.

Sourcing Materials and Addressing Common Challenges

The performance and longevity of plate heat exchangers are heavily reliant on the quality and type of materials used in their construction. Common plate materials include stainless steel (AISI 304, 316, 316L) for general applications and titanium for highly corrosive environments like seawater. Gaskets are typically made from various rubber compounds like NBR, EPDM, and Viton, chosen based on compatibility with the operating temperatures and media. For extremely corrosive fluids, specialized materials like PTFE-cushioned gaskets are available.

Common challenges encountered in plate heat exchangers, regardless of application, include:

- Fouling: The accumulation of unwanted deposits on the heat transfer surfaces, leading to reduced efficiency and increased pressure drop. Proper filtration, regular cleaning, and optimized flow dynamics are crucial for mitigation.

- Corrosion: Degradation of plate material due to chemical reactions with the media, leading to leaks and component failure. Careful material selection based on fluid properties is paramount.

- Leaks: Can occur externally (due to gasket issues or improper tightening) or internally (due to plate cracks or corrosion), leading to contamination or loss of fluid. Prompt detection and repair are essential.

- Pressure Drop Issues: Higher-than-expected pressure drop can indicate fouling or blockages, leading to increased pumping costs and reduced flow. Regular monitoring and appropriate cleaning or redesign can address this.

At Heating Formula, we understand these challenges intimately. We supply a comprehensive range of high-quality heat exchangers and spare parts that are equivalent to OEM standards, for leading brands. Our commitment is to provide reliable solutions that ensure optimal performance and longevity for your heat exchange systems. Whether you’re looking to upgrade, maintain, or troubleshoot, our expertise can guide you to the right choice.

Frequently Asked Questions (FAQ)

What is the primary benefit of using a plate heat exchanger in a geothermal water heating system?

The primary benefit is its high efficiency in transferring heat from the relatively low-temperature geothermal fluid to domestic water, thanks to its large surface area, induced turbulent flow, and true counter-current design within a compact footprint.

How often do plate heat exchangers in geothermal systems need maintenance?

Maintenance frequency depends on water quality and operating conditions. For gasketed units, regular cleaning (CIP or disassembly) is recommended, often annually or every few years, to prevent fouling. Monitoring pressure drop and thermal performance can indicate when maintenance is due.

Can I replace individual plates or gaskets in a plate heat exchanger?

Yes, in gasketed plate heat exchangers (GPHEs), individual plates and gaskets can be replaced, which is a major advantage for maintenance and capacity adjustments. However, in brazed plate heat exchangers (BPHEs), the plates are permanently sealed and cannot be individually replaced or serviced.

What are common signs that my plate heat exchanger might need servicing?

Common signs include a decrease in hot water temperature, reduced hot water flow, an increase in system pressure drop, or visible leaks around the unit. These often point to fouling, gasket deterioration, or internal issues.

Is geothermal water heating suitable for all homes?

Geothermal water heating is generally suitable for most homes, but its feasibility and efficiency can depend on factors like ground conditions for loop installation, local climate, and initial investment costs. Advances in technology, including efficient plate heat exchangers, make it a viable option for a wide range of applications.

What is the difference between an OEM and an equivalent spare part?

An Original Equipment Manufacturer (OEM) part is produced by the company that originally manufactured your heat exchanger. An equivalent spare part, like those supplied by Heating Formula, is manufactured by a different company but is designed to meet or exceed the specifications and performance of the OEM part, often at a more competitive price. Both are designed to fit and function correctly within your unit.

How does Heating Formula help with heat exchanger selection and spare parts?

Heating Formula offers expertise in selecting the right heat exchanger for your specific needs, considering factors like application, media, and desired performance. We also provide a wide range of high-quality spare parts that are equivalent to OEM standards, ensuring compatibility and reliable operation for various heat exchanger brands. Our goal is to simplify your maintenance and optimize your system’s efficiency.

For more information on heat exchanger selection, visit: https://heatingformula.com/en/gphe-selection/ To explore our range of spare parts, visit: https://heatingformula.com/en/gphe-spare-parts/ Contact us for inquiries: https://heatingformula.com/en/contact/