The Unseen Workhorse: How Plate Heat Exchangers Purify Our Water

Have you ever wondered how the water used in critical industrial processes becomes incredibly pure? It’s not simply filtered tap water. Achieving truly pure water requires a sophisticated multi-step purification process, and at the heart of this system, often working behind the scenes, are plate heat exchangers. Their journey to this vital role stretches back centuries, evolving from rudimentary heat exchange methods to the highly efficient units we rely on today.

A Brief History of Heat Exchange: From Ancient Baths to Modern Marvels

The concept of transferring heat from one substance to another is as old as civilization itself. Early humans used simple methods, like heating stones in a fire and dropping them into water, to warm liquids. Ancient Roman baths employed intricate systems of flues and hypocausts to heat water and air for public use, demonstrating an early understanding of indirect heat transfer.

Fast forward to the Industrial Revolution, and the need for more efficient heat transfer became paramount. Early industrial heat exchangers were often large, cumbersome contraptions, typically of the “shell and tube” variety. These involved one fluid flowing through tubes while another flowed around them within a larger shell. While effective, they were often bulky and challenging to maintain.

The true revolution in compact and efficient heat exchange arrived with the invention of the plate heat exchanger in the early 20th century. This design, with its thin, corrugated plates pressed together to create numerous parallel channels, offered a dramatically larger heat transfer surface area in a much smaller footprint compared to their shell and tube predecessors. This innovation paved the way for their widespread adoption across countless industries, including the critical field of water purification.

What is Primary Pure Water and Why is it So Important?

Primary pure water isn’t just clean water; it’s water meticulously stripped of almost all impurities. This includes dissolved salts, organic substances, dissolved gases, and even microscopic particles. Why go to such lengths? Because in many high-tech and sensitive industries, even minute traces of impurities can wreak havoc. For example, in pharmaceutical manufacturing, impurities can compromise product integrity. In electronics manufacturing, they can short-circuit delicate components. In power generation, they can cause scaling and corrosion in boilers and turbines.

Achieving this level of purity is a multi-layered process. It’s rare for a single piece of equipment to handle all the necessary purification steps. Instead, a combination of technologies is employed, with reverse osmosis (RO) and ion exchange being two prominent examples.

How Do Plate Heat Exchangers Fit into a Primary Pure Water System?

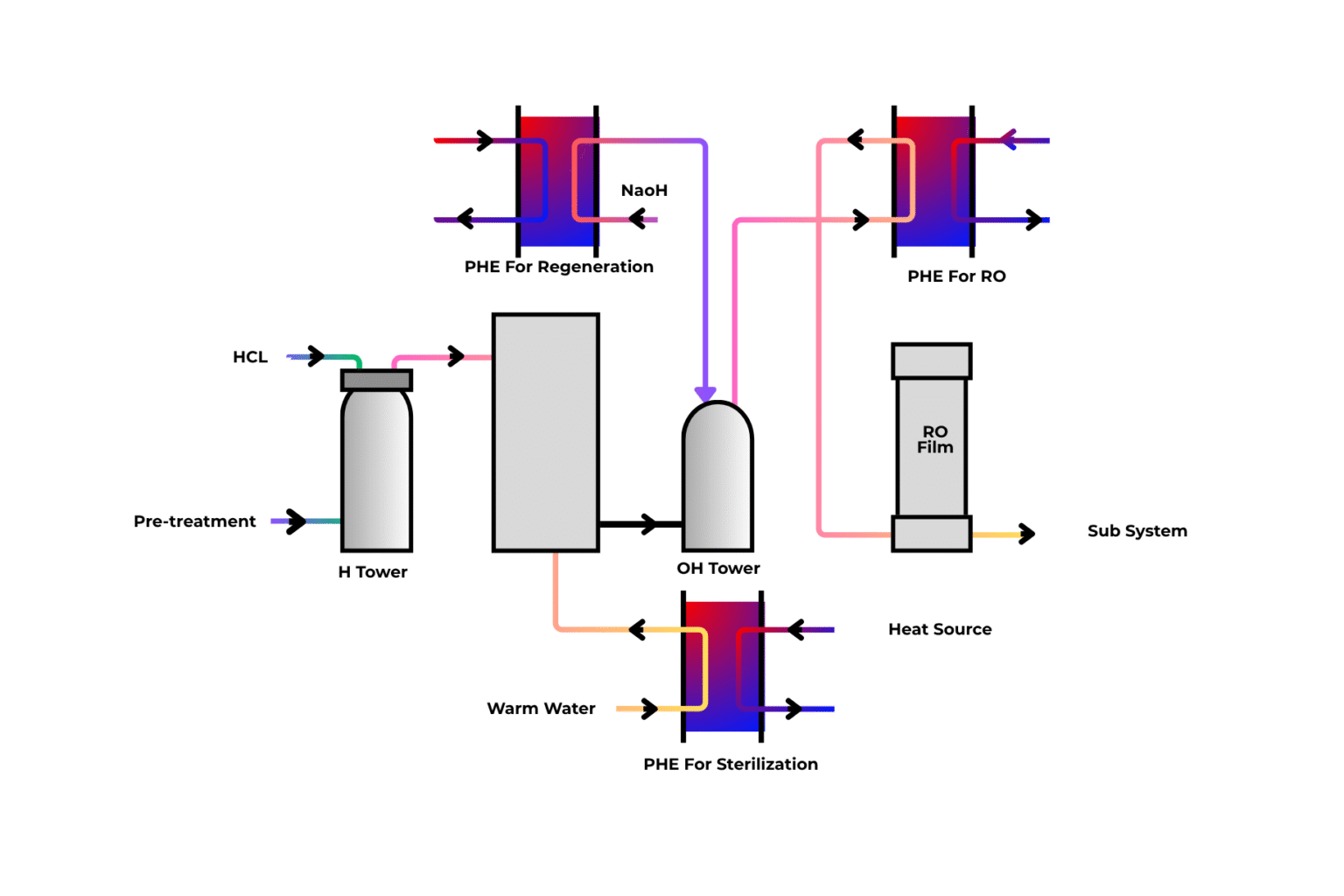

Plate heat exchangers play a crucial, though often unseen, role in optimizing the efficiency and effectiveness of primary pure water systems. Their ability to precisely control temperatures makes them indispensable at key stages of the purification process.

Optimizing Reverse Osmosis (RO) with Plate Heat Exchangers

Reverse osmosis is a membrane-based filtration process that removes dissolved inorganic solids, organic contaminants, and other impurities from water by forcing it through a semi-permeable membrane under pressure. The efficiency of RO membranes is highly dependent on the temperature of the incoming water.

This is where plate heat exchangers step in. Often, the raw water supply to an RO system might be too cold for optimal membrane performance. Colder water is more viscous, requiring higher pressure to push it through the membrane, which increases energy consumption and can reduce membrane lifespan. By pre-heating the raw water to the ideal temperature, plate heat exchangers ensure the RO membranes operate at peak efficiency, extending their life and reducing operational costs.

Supporting Ion Exchange Regeneration with Plate Heat Exchangers

Ion exchange is another vital step in producing pure water, particularly for removing dissolved salts. This process uses resin beads that “exchange” unwanted ions in the water for more desirable ones (like hydrogen or hydroxide ions). Over time, these resin beads become saturated with impurities and need to be “regenerated” to restore their effectiveness. This regeneration typically involves flushing the resins with chemical solutions, such as hydrochloric acid (HCl) or sodium hydroxide (NaOH).

Plate heat exchangers are frequently used to heat these regeneration solutions. Heating the acid or caustic solution can significantly improve the efficiency of the regeneration process, ensuring the ion exchange resins are thoroughly cleaned and ready to continue purifying water effectively. This ensures that the overall pure water system maintains its performance with minimal downtime for regeneration.

Exploring the Diverse World of Plate Heat Exchanger Designs

While the core principle of plate heat exchangers remains constant – thin plates facilitating heat transfer – their designs have diversified significantly to meet various industrial demands. Understanding these variations can help in selecting the perfect unit for a specific pure water application.

1. Gasketed Plate Heat Exchangers: The Versatile Workhorse

Gasketed plate heat exchangers (GPHEs) are perhaps the most common type and are highly versatile. They consist of a series of corrugated plates clamped together within a frame, with gaskets sealing the channels between the plates and directing the flow of fluids.

Key Features and Benefits:

- Flexibility: The number of plates can be easily adjusted, allowing for simple capacity increases or decreases. This is especially useful as water purification needs evolve.

- Ease of Maintenance: Individual plates can be removed for inspection, cleaning, or replacement, making maintenance straightforward.

- High Thermal Efficiency: The corrugated plate patterns create high turbulence, even at low flow rates, leading to exceptional heat transfer coefficients. This means more heat is transferred in a smaller space, making them highly efficient.

- Compact Footprint: Compared to shell and tube heat exchangers, GPHEs require significantly less installation space, often as little as one-third the space and one-tenth the weight. This is a huge advantage in facilities where space is at a premium.

- Prevention of Inter-mixing: Many GPHEs feature a “double seal” gasket design. In the unlikely event of a leak from one fluid channel, the fluid is directed externally, preventing it from mixing with the other fluid. This is critical in pure water systems where contamination is unacceptable.

Common Types of Gasketed Plates:

- Fishbone Plates: These are the most common type, featuring a V-shaped corrugation pattern that maximizes turbulence and heat transfer. Different angles and depths of the “fishbone” can be designed for various thermal requirements.

- Free Flow Plates: Designed for challenging media containing solids, fibers, or highly viscous fluids, these plates have wider and deeper channels to prevent clogging and fouling. While often associated with sugar processing or wastewater, they could be beneficial in raw water heating applications where suspended solids are a concern.

2. Semi-Welded Plate Heat Exchangers: For Aggressive Media

When one of the fluids is particularly aggressive (e.g., ammonia or certain chemicals used in regeneration), semi-welded plate heat exchangers offer a robust solution. In these units, pairs of plates are laser-welded together to form “cassettes.” One side of the cassette is gasketed for the non-aggressive fluid, while the welded side handles the aggressive medium.

Key Features and Benefits:

- Enhanced Safety: The welded channels prevent leakage of aggressive media to the external environment, offering superior safety.

- Durability: The welded construction allows these units to withstand extreme conditions and high pressures, extending their lifespan in demanding applications.

- Reduced Gasket Exposure: Only a ring gasket is exposed to the aggressive medium, prolonging gasket life.

- Cleanability: While one side is welded, the gasketed side still allows for opening and cleaning of the plate channels.

3. Brazed Plate Heat Exchangers: Compact and Permanent

Brazed plate heat exchangers (BPHEs) are compact, permanently sealed units where thin corrugated plates are brazed together with a filler metal (like copper or nickel). This creates a very robust and leak-proof heat exchanger.

Key Features and Benefits:

- Extreme Compactness: Brazing eliminates the need for gaskets and frames, resulting in an incredibly small footprint and lightweight design, making them ideal for installations with limited space.

- High Pressure and Temperature Resistance: The brazed construction provides exceptional resistance to high pressures and temperatures.

- Cost-Effective: Their simplified construction and suitability for mass production often make them more economical than other types for certain applications.

Considerations:

- Not Openable: Unlike gasketed units, brazed plate heat exchangers cannot be disassembled for mechanical cleaning. This means chemical cleaning (CIP) is the primary maintenance method.

- Material Compatibility: The brazing material must be compatible with both fluids to prevent corrosion.

4. Plate and Shell Heat Exchangers: The Best of Both Worlds

Plate and shell heat exchangers combine the best features of plate and shell & tube designs. They feature a fully welded plate pack enclosed within a robust shell.

Key Features and Benefits:

- High Pressure and Temperature: They can handle very high pressures (up to 40 bar) and temperatures (up to 400°C), often exceeding the capabilities of traditional gasketed plate heat exchangers.

- No Gaskets on Plate Side: The fully welded plate pack eliminates gaskets on the process side, making them ideal for aggressive media or applications where leakage is absolutely critical to avoid.

- Compact and Efficient: They offer a significantly smaller footprint and higher thermal performance than traditional shell and tube exchangers.

- Robustness: Highly resistant to thermal shocks and pressure fatigue, making them suitable for cyclic duties.

Considerations:

- Not Openable for Mechanical Cleaning: Similar to brazed units, the fully welded plate pack means they cannot be opened for mechanical cleaning, relying on CIP.

5. Spiral Heat Exchangers: Tackling the Toughest Fluids

For the most challenging media – sludges, slurries, highly viscous liquids, or those containing significant fibers and solids – spiral heat exchangers are the definitive solution. They are constructed from two long metal sheets coiled concentrically to form two distinct, single-pass channels.

Key Features and Benefits:

- Self-Cleaning Effect: The single-channel design creates high shear rates, which naturally dislodge deposits and prevent clogging. This significantly extends intervals between cleaning.

- Excellent for Fouling Media: Their wide, unimpeded channels are specifically designed to handle fluids that would quickly foul other heat exchanger types.

- High Thermal Efficiency: Despite handling difficult fluids, they still achieve very high heat transfer coefficients due to the long, curved flow paths and counter-current flow.

- Minimized Space: They are very compact for their capacity.

Considerations:

- Specialized Design: Their unique design makes them less flexible for applications with very clean fluids where other plate heat exchanger types might be more economical.

Avoiding Common Mistakes: Ensuring Longevity and Performance

While plate heat exchangers are robust and efficient, certain common mistakes can lead to reduced performance, increased maintenance, or even system failure. Awareness and preventative measures are key to maximizing their lifespan.

1. Incorrect Sizing and Selection: A Recipe for Trouble

One of the most frequent pitfalls is choosing a heat exchanger that isn’t perfectly matched to the specific application’s thermal and flow requirements. An undersized unit will struggle to meet demand, leading to inefficient operation and potential component stress. An oversized unit, while seemingly robust, can lead to lower flow velocities, which ironically increases the risk of fouling.

- Solution: Always provide detailed process data, including flow rates, temperatures, fluid properties (viscosity, particle content, corrosiveness), and desired thermal output to the manufacturer. Utilizing specialized selection software can help pinpoint the ideal unit. Our GPHE selection tool can guide you to the right unit for your needs: https://heatingformula.com/en/gphe-selection/

- Key Consideration: Understanding the “NTU value” (Number of Heat Transfer Units) is crucial, as it directly relates to the thermal requirements and thus the plate length needed for optimal efficiency.

2. Neglecting Water Quality and Fouling Management

Fouling – the accumulation of unwanted substances on heat transfer surfaces – is the single biggest enemy of heat exchanger efficiency. In pure water systems, even trace impurities can lead to scale buildup, biological growth, or particle deposition.

- Solution:

- Pre-filtration: Install appropriate filters or strainers upstream of the heat exchanger to remove particulate matter, especially in raw water lines. The mesh size should be carefully chosen to prevent clogging while allowing flow.

- Chemical Cleaning (CIP): Implement regular Cleaning-in-Place (CIP) procedures. This involves circulating a cleaning solution through the unit without disassembly. Choosing the correct chemical cleaner (acidic for scale, alkaline for organic fouling) is vital to avoid damaging the plates or gaskets.

- Mechanical Cleaning: For heavier fouling, periodic disassembly and manual cleaning with soft brushes and high-pressure washers (at a safe distance) are necessary.

- Anti-Fouling Systems: For challenging raw water sources like seawater, consider advanced systems like automatic back-flushing strainers or hot water circulation systems to prevent marine growth.

- Key Consideration: Fouling reduces heat transfer efficiency and increases pressure drop. The optimal cleaning schedule balances the cost of energy losses due to fouling against the cost of cleaning.

3. Improper Installation and Piping

Mistakes during installation can lead to long-term operational issues.

- Solution:

- Level Foundation: Ensure the heat exchanger is installed on a firm, level foundation to prevent stress on the frame and plates.

- Proper Piping Support: Never allow piping to exert load on the heat exchanger nozzles. Use independent pipe supports.

- Expansion Joints: For units that undergo significant temperature changes or have long piping runs, expansion joints should be used to absorb thermal expansion and prevent stress on the connections.

- Maintenance Space: Always ensure adequate space around the unit for maintenance, including disassembly and cleaning.

- Key Consideration: Incorrect piping can lead to uneven flow distribution across plates, reducing efficiency and increasing the risk of localized fouling or erosion.

4. Over-tightening or Under-tightening the Plate Pack (for Gasketed Units)

The “tightening length” of a gasketed plate heat exchanger is crucial. Over-tightening can crush gaskets and deform plates, leading to leaks. Under-tightening won’t provide an adequate seal, also causing leaks.

- Solution: Always follow the manufacturer’s specified tightening length (A-dimension) found on the nameplate or assembly drawing. Use appropriate tools like ratchet spanners or automatic tightening devices and follow the recommended tightening sequence.

- Key Consideration: Gaskets naturally lose elasticity over time, which can lead to leakage and necessitate re-tightening or replacement.

5. Ignoring Gasket Compatibility and Lifespan

Gaskets are critical sealing components, and their material must be compatible with the fluids and temperatures involved.

- Solution:

- Material Selection: Ensure the gasket material (e.g., NBR, EPDM, Viton, PTFE) is chemically compatible with both the process fluid and any cleaning agents.

- Regular Replacement: Gaskets have a finite lifespan and should be replaced at recommended intervals, even if no visible leaks are present, as they can harden, crack, or swell over time.

- Proper Storage: Spare gaskets should be stored in cool, dark conditions, away from UV light, and without heavy objects placed on them.

- Key Consideration: Deteriorated gaskets are a common cause of external leakage and internal fluid intermixing.

Applications of Plate Heat Exchangers in Various Industries

Beyond pure water systems, plate heat exchangers are indispensable across a vast array of industries due to their high efficiency and versatility.

- HVAC (Heating, Ventilation, and Air Conditioning): Used for district heating and cooling, central cooling systems, and heat recovery.

- Food and Beverage: Critical for pasteurization, sterilization, cooling, and heat recovery in dairy, juice, beer, and other food processing. They handle delicate products with minimal thermal impact. Specialty designs like “Free Flow” plates are ideal for viscous products or those with pulp.

- Marine and Offshore: Essential for central cooling, lubrication oil cooling, and engine jacket water cooling on vessels and platforms. Sea water applications require careful consideration of fouling and corrosion.

- Chemical and Petrochemical: Used for waste heat recovery, condensation, evaporation, and heating/cooling of various chemical streams, even aggressive ones with semi-welded units.

- Power Generation: Employed in cogeneration for waste heat recovery, cooling generator components, and district heating solutions using renewable energy sources like geothermal or solar.

- Pulp and Paper: Used for heat recovery from fibrous waste streams and cooling/heating of pulpy materials.

- Sugar Processing: A critical application for Free Flow plate heat exchangers, handling molasses, syrup, and other sugar-rich fluids, often with high viscosity and particle content.

- Mining and Metallurgy: Cooling of circulating water, hydraulic oil, and lubricating oil in blast furnaces, continuous casting, and rolling mills.

Sourcing Materials and Spare Parts: The Heating Formula Advantage

Ensuring the longevity and optimal performance of your plate heat exchangers hinges on reliable access to high-quality spare parts and expert support. When sourcing components, it’s crucial to choose suppliers who understand the intricacies of these precision-engineered units.

At Heating Formula, we specialize in supplying heat exchangers and spare parts that are equivalent to OEM standards. This means you get the same quality, performance, and reliability as original manufacturer parts, but often with better availability and competitive pricing. We offer a comprehensive range of spare parts including plates, gaskets, and frame components.

Whether you need replacement plates for a standard unit, specialized gaskets for aggressive media, or advice on optimizing your heat exchange system, Heating Formula is your trusted partner. We pride ourselves on providing solutions that keep your operations running smoothly and efficiently. Feel free to explore our GPHE spare parts section for more details: https://heatingformula.com/en/gphe-spare-parts/

Common Problems and Their Solutions: A Troubleshooting Guide

Even with the best design and maintenance, issues can arise. Knowing how to identify and address common problems can significantly reduce downtime and prevent further damage.

1. Reduced Heat Transfer Performance

- Possible Causes: Fouling on the heat transfer surfaces (scale, slime, particles), insufficient flow rate, or incorrect fluid temperatures.

- Solution: Perform chemical (CIP) or mechanical cleaning to remove fouling. Verify actual flow rates against design specifications. Ensure proper temperature control of incoming fluids. Consider installing inline filters if foreign debris is present in the media.

2. High Pressure Drop or Reduced Flow Rate

- Possible Causes: Clogging of port holes or plate channels due to fouling or large particulates.

- Solution: Clean the heat exchanger. Identify the source and size of particulates; consider installing strainers or upgrading to Free Flow plates if the media contains solids. Ensure proper flushing of pipes before startup to prevent debris entry.

3. External Leakage

- Possible Causes: Aged or deteriorated gaskets (hardened, cracked, swollen), improper tightening of the plate pack, damaged gasket grooves, or foreign material on sealing surfaces. Hydraulic hammering can also dislodge gaskets.

- Solution: Replace aged or damaged gaskets with compatible materials. Re-tighten the plate pack to the correct dimensions. Inspect gasket grooves for deformation. Ensure proper start-up and shutdown procedures to avoid pressure surges.

4. Internal Leakage (Mixing of Fluids)

- Possible Causes: Cracked or corroded plates, or incorrect plate assembly after maintenance.

- Solution: Disassemble the unit to identify and replace damaged plates. Perform a hydro test to pinpoint the exact location of the leak. Ensure plates are assembled in the correct order, checking the “honeycomb” pattern on the side of the unit. Consider upgrading plate material for better corrosion resistance if the issue is recurring.

5. Uneven Temperature Distribution (in parallel units)

- Possible Causes: Uneven flow distribution between parallel heat exchangers, often due to differing operating conditions from design parameters.

- Solution: Re-design piping to ensure more even flow distribution. Adjust flow rates to match design parameters. If necessary, consider adding another unit in parallel or replacing existing units with larger port sizes for better flow.

Conclusion

Plate heat exchangers, with their remarkable history of innovation and continuous evolution, are far more than simple components; they are critical enablers of efficiency, purity, and safety across a multitude of industries. In the specialized realm of primary pure water systems, they are indispensable, silently ensuring the precise temperature control needed for optimal RO and ion exchange processes.

By understanding their diverse types, avoiding common operational pitfalls, and partnering with reliable suppliers like Heating Formula for high-quality spare parts and expert guidance, industries can unlock the full potential of these essential workhorses. The pursuit of purity is a continuous journey, and plate heat exchangers remain at the forefront, ensuring that the vital resource of water is as clean and precise as modern applications demand.

For any inquiries or further assistance, please don’t hesitate to contact us: https://heatingformula.com/en/contact/

FAQ

Q1: What is primary pure water and why is it used? A1: Primary pure water is water that has undergone extensive treatment to remove salts, organic substances, dissolved gases, and fine particles. It is used in industries like pharmaceuticals, electronics, and power generation where even trace impurities can cause significant problems or compromise product quality.

Q2: How do plate heat exchangers contribute to reverse osmosis (RO) systems? A2: Plate heat exchangers are often used to pre-heat the raw water before it enters the RO membranes. This is because RO membrane efficiency is highly dependent on water temperature; pre-heating reduces water viscosity, lowers energy consumption, and extends membrane lifespan.

Q3: Can plate heat exchangers be used with aggressive chemicals in water treatment? A3: Yes, certain types like semi-welded plate heat exchangers are specifically designed for aggressive media. They feature welded plate cassettes on one side to contain corrosive fluids, ensuring safety and durability.

Q4: What are the main differences between gasketed and brazed plate heat exchangers? A4: Gasketed plate heat exchangers can be disassembled for cleaning and maintenance, offering flexibility in capacity and serviceability. Brazed plate heat exchangers are permanently sealed, compact, and highly resistant to pressure and temperature, but cannot be opened for mechanical cleaning.

Q5: How can fouling in a plate heat exchanger be prevented or managed? A5: Fouling can be prevented by installing upstream filters or strainers. It is managed through regular chemical cleaning (CIP) without disassembly, or periodic mechanical cleaning by disassembling the unit. For challenging water sources like seawater, specialized anti-fouling systems can also be employed.

Q6: What should I do if my plate heat exchanger is leaking externally? A6: External leakage is often caused by aged or damaged gaskets, improper tightening, or foreign material on the sealing surfaces. The solution typically involves replacing the gaskets, re-tightening the plate pack to the correct specifications, and ensuring proper operating procedures to avoid pressure surges.

Q7: Where can I find spare parts for my plate heat exchanger? A7: Companies like Heating Formula supply heat exchanger spare parts, including plates, gaskets, and frame components, that are equivalent to OEM quality. This ensures continued optimal performance of your unit.

Q8: What is the importance of “tightening length” in gasketed plate heat exchangers? A8: The tightening length is a critical dimension that ensures proper sealing of the plate pack. Over-tightening can damage plates and gaskets, while under-tightening leads to leaks. Always follow the manufacturer’s specified tightening length found on the unit’s nameplate.