Revolutionize Your HVAC System with Brazed Plate Heat Exchangers

Maximize efficiency, minimize costs, and enhance performance by integrating brazed plate heat exchangers (BPHEs) into your heating, ventilation, and air conditioning (HVAC) systems. These compact and powerful components offer a significant upgrade over traditional heat exchangers, leading to substantial energy savings and a smaller environmental footprint.

Brazed plate heat exchangers are engineered for superior thermal performance. They consist of a series of corrugated metal plates, typically made of stainless steel, which are brazed together with copper or nickel. This construction creates a series of intricate channels for hot and cold fluids to flow on opposite sides of the plates. The large surface area and the turbulent flow induced by the corrugated pattern allow for exceptionally efficient heat transfer between the two fluids without them ever mixing.

The Clear Advantages of a Compact Powerhouse

Integrating BPHEs into your HVAC system brings a multitude of benefits that directly contribute to its optimization:

- Unmatched Thermal Efficiency: BPHEs boast significantly higher heat transfer coefficients compared to conventional shell-and-tube heat exchangers. This superior efficiency translates to lower energy consumption for heating and cooling, directly impacting your utility bills.

- Space-Saving Design: Their compact and lightweight nature means they occupy a fraction of the space required by other heat exchanger types of the same capacity. This is a crucial advantage in modern buildings where space is often at a premium, allowing for more flexible installation and system design.

- Enhanced Reliability and Durability: The brazing process creates a hermetically sealed unit with no gaskets, which are common points of failure and leakage in other plate heat exchanger designs. This robust construction ensures long-term, maintenance-free operation.

- Cost-Effectiveness: The combination of lower initial cost, reduced installation expenses due to their smaller size, and significant energy savings over their lifespan makes BPHEs a highly cost-effective solution for HVAC applications.

- Versatility in Application: BPHEs are incredibly versatile and can be effectively utilized in various HVAC processes, including:

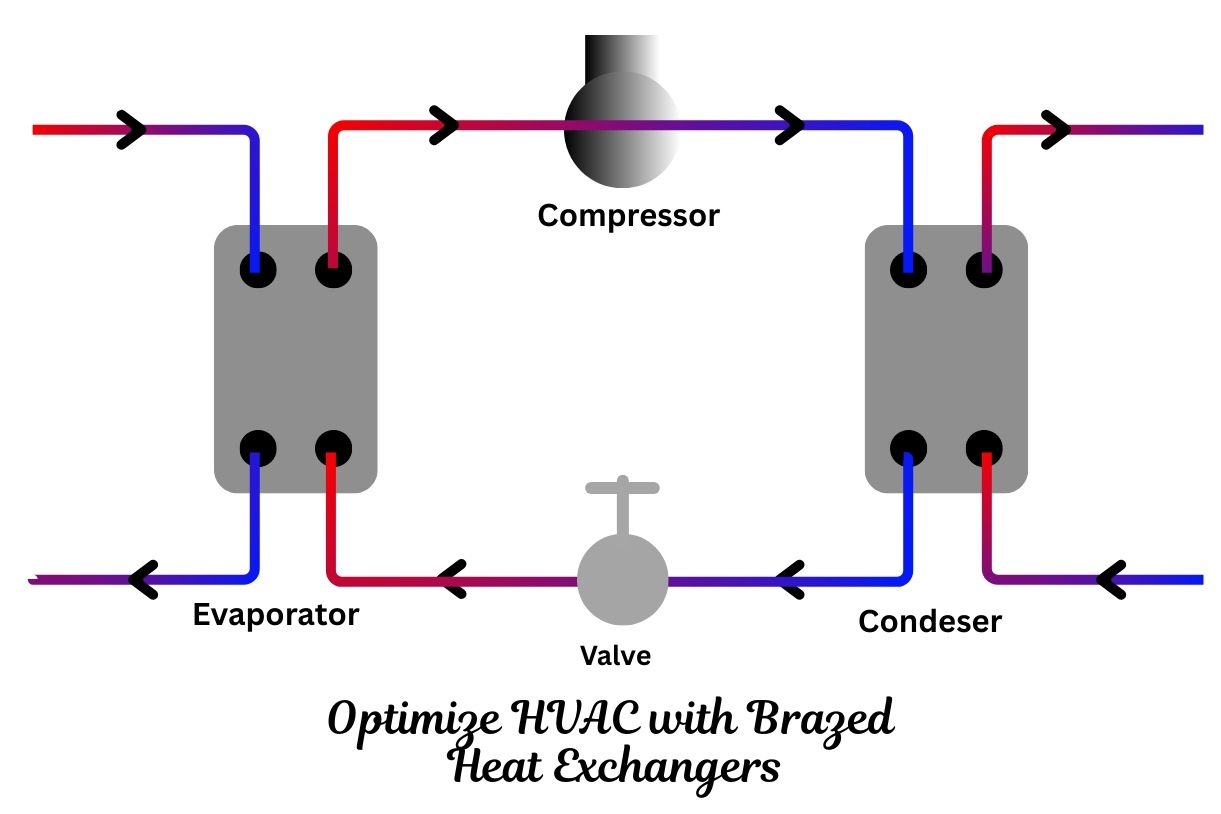

- Evaporators and Condensers: Their high efficiency makes them ideal for refrigerant phase change applications.

- Chillers: They excel at transferring heat between the refrigerant and the chilled water loop.

- Heat Pumps: BPHEs are effective in both heating and cooling modes, making them a core component of modern heat pump systems.

- Domestic Hot Water Production: They can efficiently transfer heat from a primary heating circuit to provide domestic hot water.

- Radiant Floor Heating: Their compact size and efficiency are well-suited for underfloor heating systems.

Strategies for Optimizing Your HVAC System with BPHEs

To fully leverage the potential of brazed plate heat exchangers and optimize your HVAC system, consider the following strategies:

Proper Sizing and Selection

The cornerstone of an optimized system is selecting the correctly sized BPHE for your specific application. This involves a careful analysis of several key factors:

- Heat Load: Accurately calculate the heating or cooling demand of the space or process.

- Flow Rates: Determine the flow rates of both the hot and cold fluids that will pass through the heat exchanger.

- Temperature Differentials: Consider the inlet and outlet temperatures of both fluids. The Logarithmic Mean Temperature Difference (LMTD) is a crucial calculation for determining the thermal driving force.

Undersizing a BPHE will result in inadequate heating or cooling, while oversizing can lead to unnecessary costs and inefficient operation. Many manufacturers provide software to assist in the selection process based on your specific operating conditions.

System Design and Integration

Proper integration of the BPHE into the overall HVAC system design is critical for optimal performance. This includes:

- Piping and Connections: Ensure that the piping is correctly sized and configured to minimize pressure drop and ensure adequate flow to the heat exchanger.

- Controls and Automation: Implement a control strategy that modulates the flow rates through the BPHE based on the actual heating or cooling demand. This can significantly improve part-load efficiency and overall system performance.

- Water Quality: While BPHEs are generally robust, poor water quality can lead to scaling and fouling, which will reduce their efficiency. Implementing appropriate water treatment and filtration can prolong the life and performance of the heat exchanger.

Regular Maintenance and Monitoring

Although BPHEs are known for their low maintenance requirements, periodic checks can ensure they continue to operate at peak efficiency.

- Performance Monitoring: Regularly monitor the temperature and pressure differentials across the heat exchanger. A significant change could indicate fouling or other issues.

- Cleaning: In applications where fouling is a risk, a cleaning-in-place (CIP) procedure can be performed without disassembling the unit to restore its thermal performance.

By embracing the efficiency, compact size, and reliability of brazed plate heat exchangers and implementing these optimization strategies, you can unlock significant improvements in your HVAC system’s performance, leading to a more sustainable and cost-effective solution for climate control.