Decoding Heat Exchangers: A Comprehensive User Manual and Application Guide

Heat exchangers are the unsung heroes of industrial processes, playing a critical role in everything from climate control to power generation. As a leading heat exchanger manufacturer based in Turkey, Heating Formula is dedicated to providing efficient, reliable, and meticulously engineered plate heat exchangers (PHEs) and compatible spare parts. This comprehensive guide serves as a user manual, detailing the optimal operation and maintenance of Heating Formula plate heat exchangers, alongside a deeper dive into their diverse applications across various industries.

The Enduring Legacy of Heat Exchangers: A Brief History

The concept of heat exchange has been fundamental to human progress for centuries. Early applications, though rudimentary, laid the groundwork for modern thermal management. From ancient heating systems to rudimentary industrial cooling, the core principle—transferring thermal energy from one medium to another without direct contact—has remained constant. Over time, innovations in materials and design have transformed simple heat exchange into the sophisticated, highly efficient systems we see today, with plate heat exchangers emerging as a compact and versatile solution.

Understanding Your Heating Formula Plate Heat Exchanger

At its core, a Heating Formula Plate Heat Exchanger is designed for maximum thermal efficiency and ease of maintenance. Understanding its components and operating principles is key to ensuring its longevity and optimal performance.

What are the Key Components of a Plate Heat Exchanger?

A typical plate heat exchanger consists of several essential parts that work in harmony to facilitate heat transfer:

Heat Transfer Plates: These thin, corrugated plates form the primary heat exchange surface. Their unique design promotes high turbulence and maximizes the heat transfer area.

Gaskets: Positioned between each plate, gaskets create a sealed channel for fluids and direct their flow through the plate pack. Heating Formula offers various gasket materials like NBR, EPDM, and Viton, chosen based on fluid compatibility and temperature requirements.

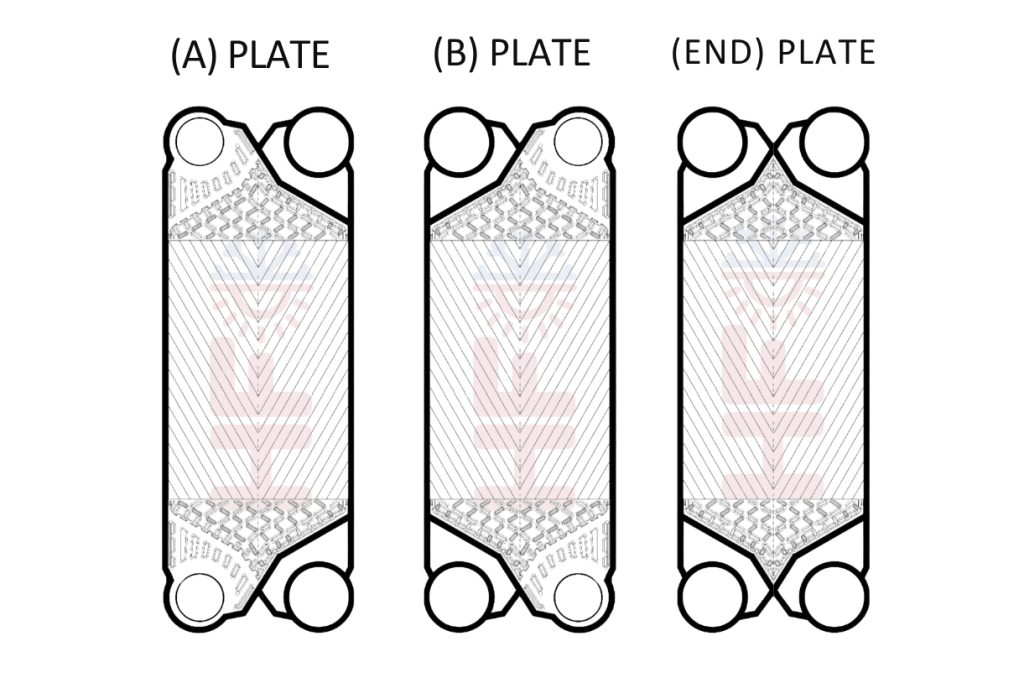

Start and End Plates in Plate Heat Exchangers

Although only two gasket designs have been discussed so far, there are actually three distinct gasket types used in plate heat exchangers. Gaskets alternate between plates to direct flow properly, except at the first and last plates in the stack—these are known as the start plate and end plate, respectively.

These plates are positioned against the fixed cover and movable cover, and their primary purpose is to block fluid flow into the spaces between the plates and the covers. This ensures that the covers—being thick, flat, and non-corrugated—do not participate in heat exchange. This design choice is logical, as the covers are structurally robust but thermally inefficient compared to the corrugated plates.

Fixed Frame (Head): This stationary end plate houses the inlet and outlet connections for the fluids.

Movable Frame (Follower): This plate slides along the carrying bar, compressing the plate pack against the fixed frame with tightening bolts.

Carrying Bar & Guiding Bar: These bars support and align the plates within the frame.

Tightening Bolts: These bolts clamp the plates tightly between the fixed and movable frames, creating a sealed unit.

Each Heating Formula PHE is equipped with a nameplate on the front of the fixed plate, detailing critical information such as design pressure, design temperature, and manufacturing number. It is crucial to preserve this nameplate for future reference and maintenance.

How Do Plate Heat Exchangers Work?

The fundamental principle behind a plate heat exchanger involves two fluids, at different temperatures, flowing through alternating channels created by the stacked plates. The thin metal plates separate the fluids, preventing them from mixing while allowing heat to transfer from the hotter fluid to the colder fluid across the plate surface.

Flow Configuration in Plate Heat Exchangers

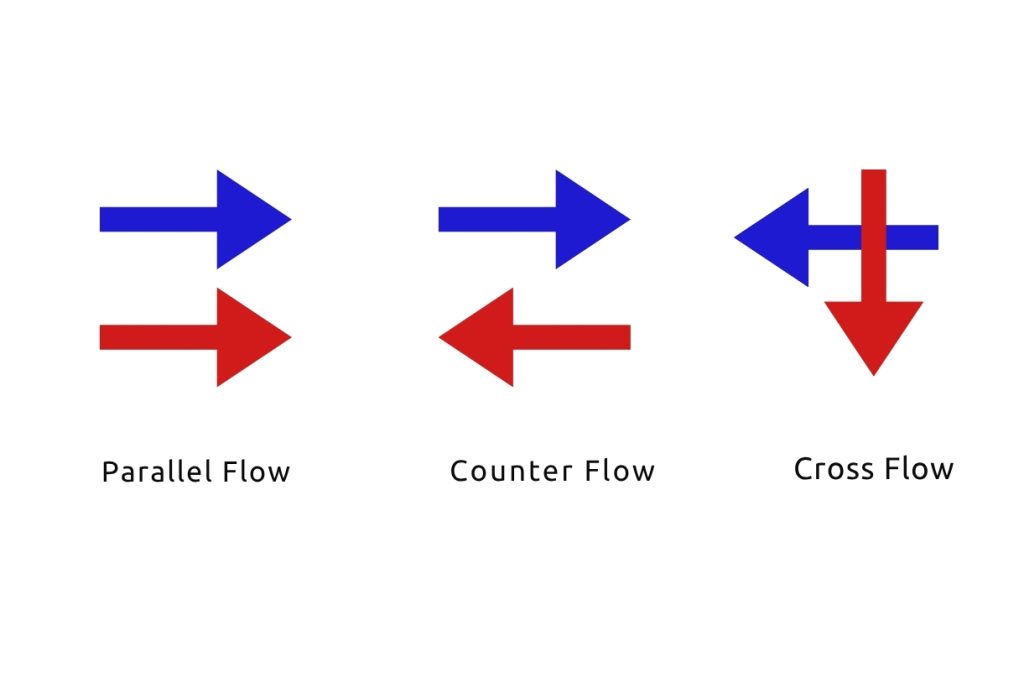

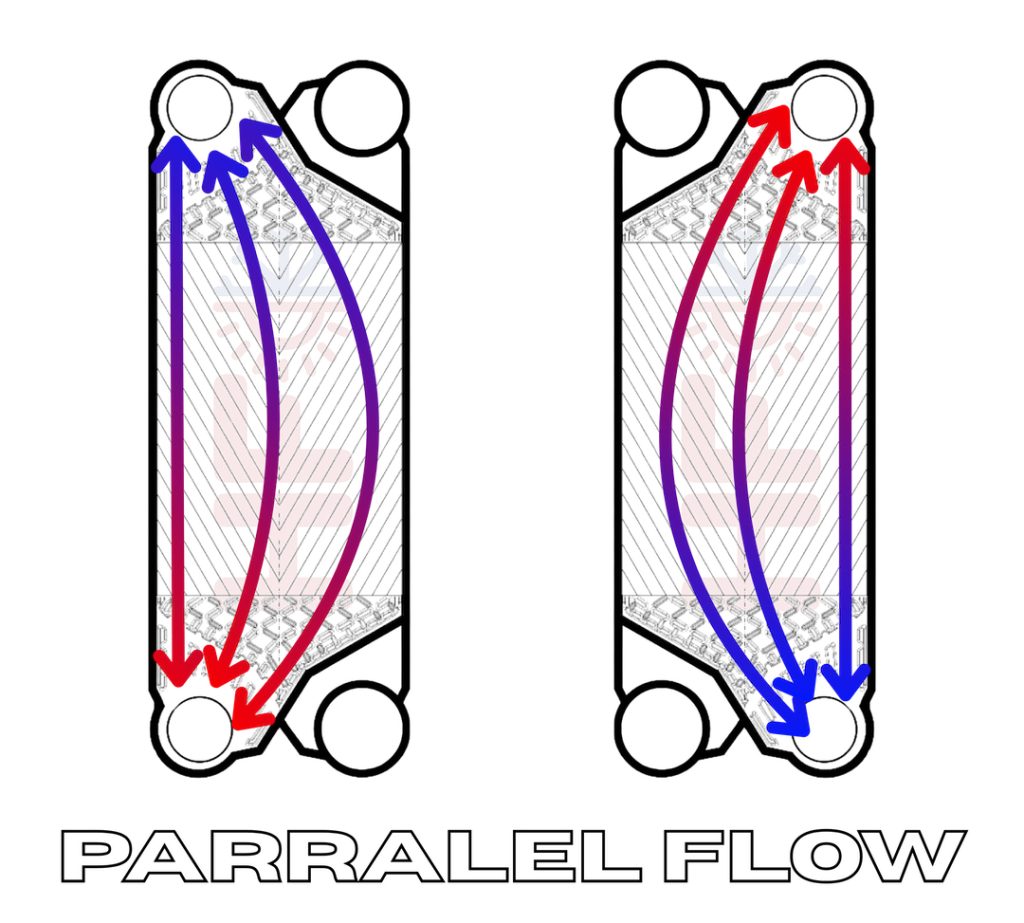

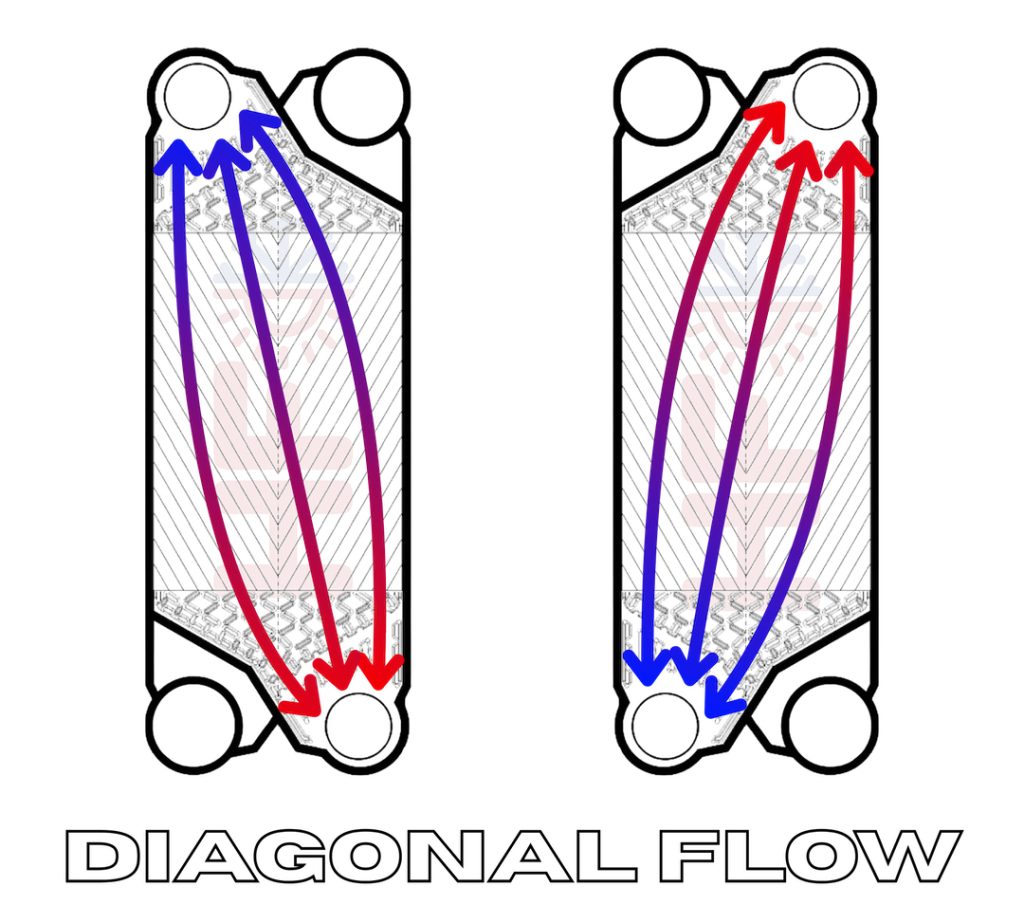

Flow through a plate heat exchanger can be arranged as parallel flow, crossflow, or counterflow. Among these, counterflow—also known as contra flow—is the most commonly used due to its superior heat transfer efficiency. In counterflow arrangements, the hot and cold fluids move in opposite directions, maximizing the temperature gradient across the heat transfer surface and enhancing thermal performance.

Plate heat exchangers (PHEs) can be also configured for diagonal, parallel, each optimized for different thermo-hydraulic performance requirements. For example, diagonal flow can help balance pressure drop and temperature distribution in asymmetrical systems, while parallel flow may be used where compact design or gentle thermal gradients are needed. Furthermore, PHEs can be tailored for multi-pass flow, asymmetric channel design, or multi-stream configurations, depending on process demands such as heat recovery, phase change, or corrosive media handling.

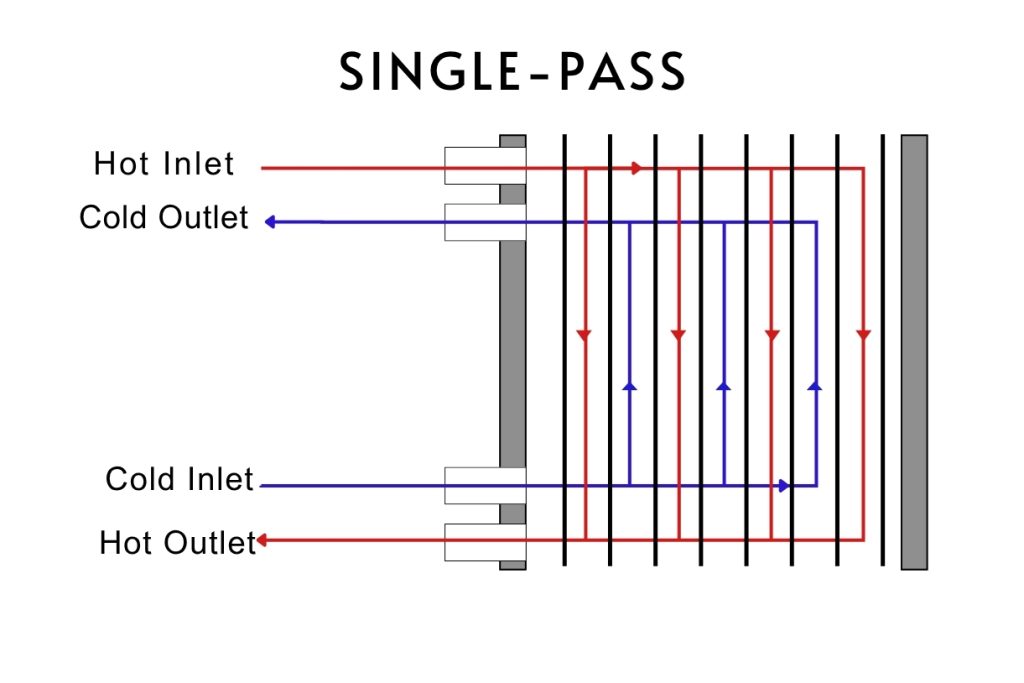

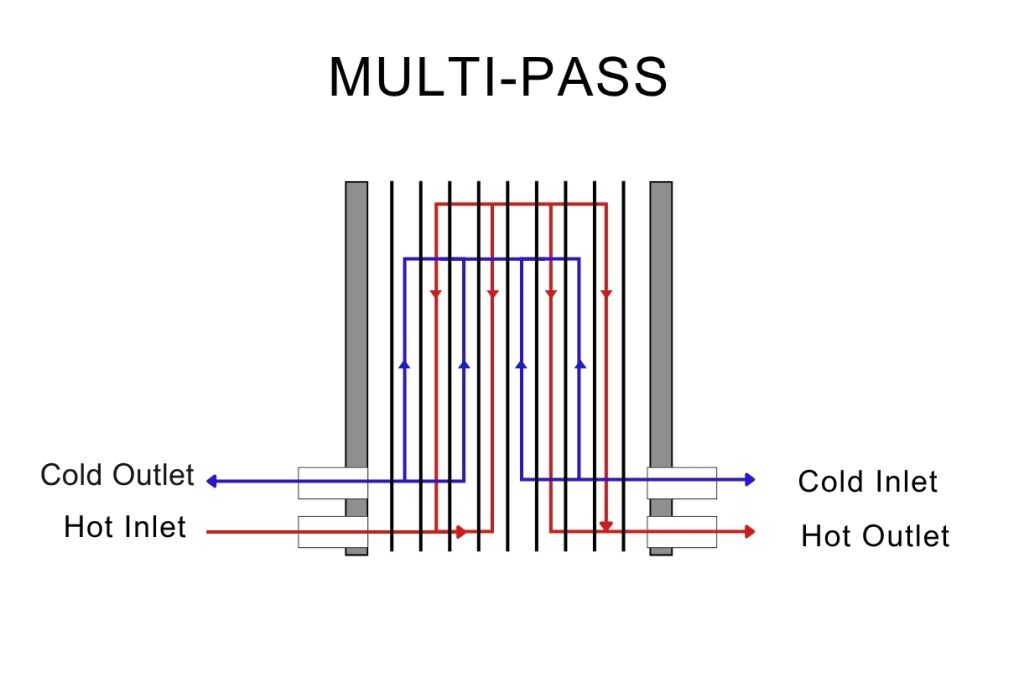

single-pass or multi-pass operations. Single-pass designs are simpler and ideal for large temperature differences, while multi-pass configurations enhance heat transfer efficiency for smaller temperature differentials, albeit with increased pressure drop.

Plate Materials vs. Compatible Fluids and Standard Thicknesses

| Plate Material | Compatible Media | Available Thickness (mm) |

|---|---|---|

| 304 Stainless Steel (SS) | Pure water, food-grade oils, ethanol | 0.4, 0.5, 0.6 |

| 316 Stainless Steel (SS) | Water, edible oils, ethanol, carbonic acid, low-temp 20% sulfuric acid (chloride-free) | 0.4, 0.5, 0.6 |

| 254 SMO Stainless Steel | Low-temp 20% sulfuric acid (chloride-free), inorganic acids | 0.6 |

| Titanium | Seawater, chloride-containing solutions (up to 130°C) | 0.5, 0.6 |

| Titanium-Palladium (Ti-0.2Pd) | 70% nitric acid, hydrochloric acid with copper and iron ions | 0.5, 0.6 |

| Hastelloy C-276 | 98% sulfuric acid, nitric acid, 40% hydrochloric acid, 50% phosphoric acid | 0.6 |

| Nickel 200/201 | High-concentration alkaline solutions (50%–70%) | 0.6 |

| Graphite | Highly corrosive fluids and aggressive chemical media | 0.6 |

Sealing Gasket Materials: Temperature Ratings and Compatible Media

| Gasket Material | Temperature Range (°C) | Suitable Media Types |

|---|---|---|

| EPDM (Ethylene Propylene Diene Monomer) | -25 to 140°C | Water, aqueous solutions, mild acids, mild bases |

| EPDM HT (High-Temperature EPDM) | -20 to 150°C | Hot water, aqueous solutions, diluted acids and bases |

| NBR (Nitrile Rubber) | -30 to 100°C | Water, fats, vegetable oils, mineral oils, ethanol, glycol, aqueous solutions |

| HNBR (High-Temp Nitrile Rubber) | -30 to 120°C | Water, aqueous solutions, fats, vegetable oils, mineral oils, ethanol, glycol |

| FKM/Viton-B (Fluoro Rubber – Type B) | -15 to 150°C | Strong inorganic acids (oxidizing), alkalis, salts, fuels, petroleum products, solvents |

| FKM/Viton-G (Fluoro Rubber – Type G) | -15 to 180°C | Steam, hot water, high-temperature mineral oils, aggressive solvents |

| CR (Chloroprene Rubber / Neoprene) | -30 to 120°C | Ammonia, fluorinated refrigerants |

Applications and Material Guidelines

| Type | Description | Common Applications |

|---|---|---|

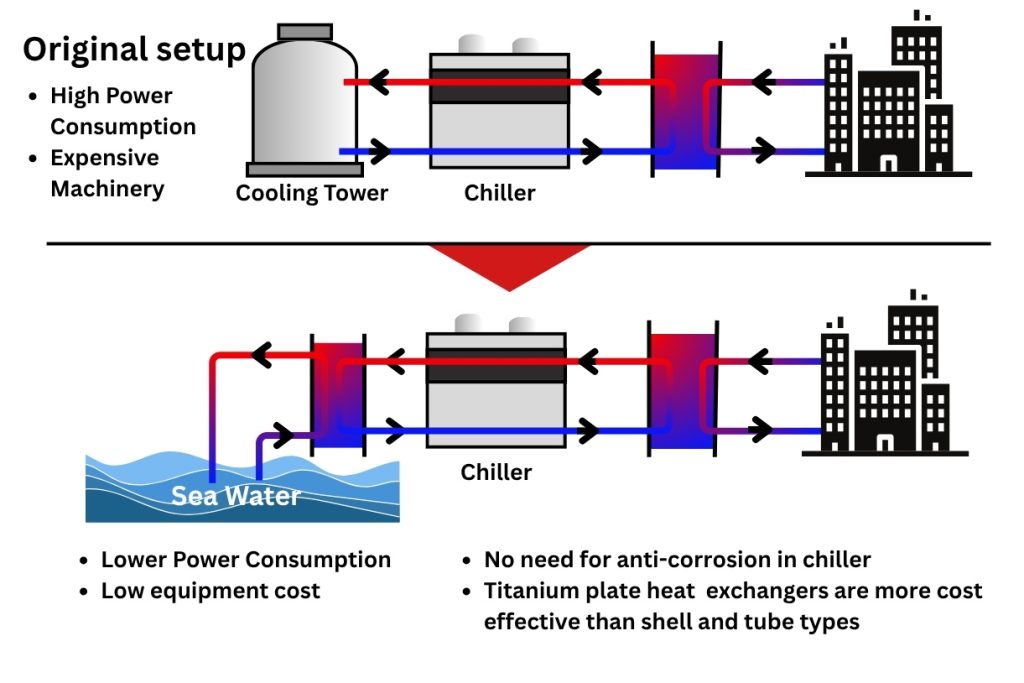

| Water/Water | Most common type; water is either cooled or heated using another water stream from a lake, river, sea, or cooling tower. | – Swimming pool heating – HVAC systems – Cooling water in industrial plants – Power industry – central cooling – Chemical industry – process cooling |

| Water/Oil | Used in industries to cool oil using water. The cooled water can be repurposed, e.g., for domestic hot water. Special plate materials may be needed for synthetic oils. | – Hydraulic oil cooling – Quench oil cooling – Motor oil cooling in test rigs – Applications with oil concentrations below 5% |

| Water/Glycol | Used where freezing is a concern. Glycol lowers the freezing point of water but requires more surface area due to lower heat capacity. | – Refrigerant/brine loops in heat pumps – Cooling in industrial processes – Solar heating systems – Air conditioning chillers |

| Chloride Content (ppm) | Recommended Plate Material |

|---|---|

| 10 ppm | 304, 316 |

| 25 ppm | 304, 316 |

| 50 ppm | 316 |

| 80 ppm | 316 |

| 150 ppm | Titanium (Ti) |

| 300 ppm | Titanium (Ti) |

Applications Across Diverse Industries

Heating Formula plate heat exchangers are integral to thermal management across a wide array of industries, each with unique demands and operating conditions.

Why are Heat Exchangers Crucial in HVAC Systems?

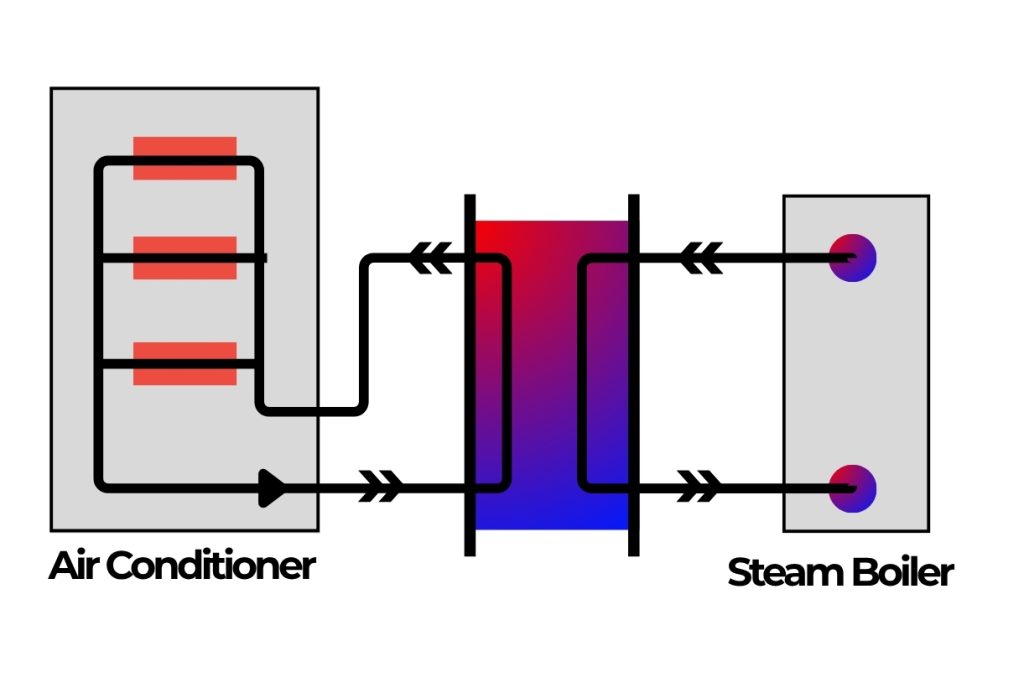

In HVAC (Heating, Ventilation, and Air Conditioning) systems, heat exchangers are vital for efficient climate control and energy management in buildings. They enable precise temperature regulation by transferring heat between air and water or other heat transfer fluids. Heating Formula’s gasketed plate and frame heat exchangers are specifically designed to balance energy demand and reduce system losses within HVAC networks.

How Do Heat Exchangers Support the Food & Beverage Sector?

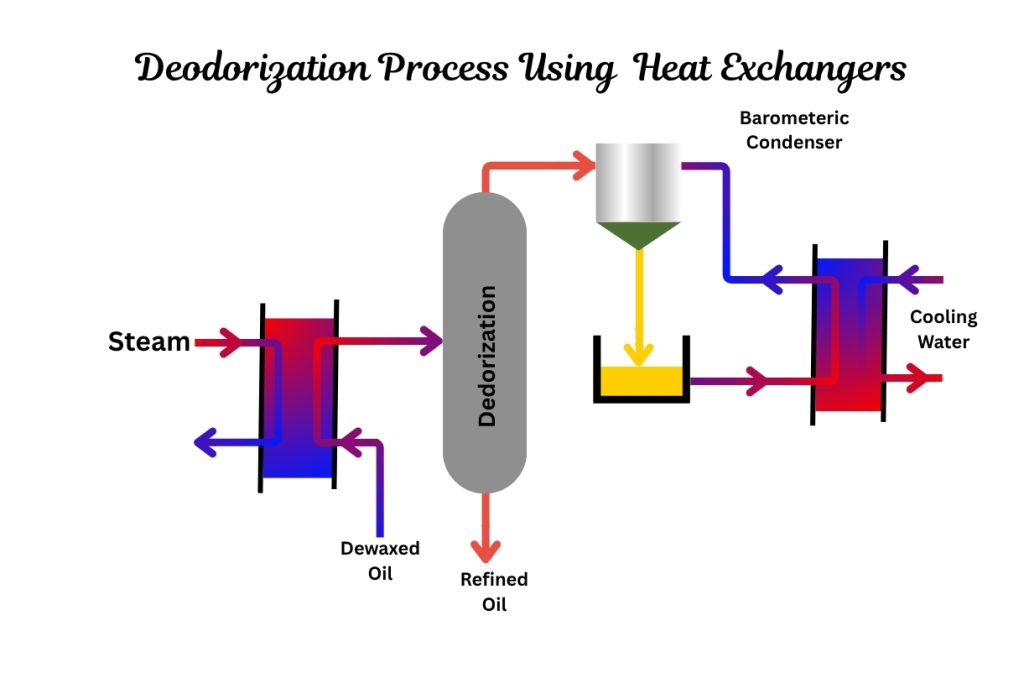

The food and beverage industry demands rigorous hygiene and precise temperature control for product quality and safety. Heat exchangers are used for processes like pasteurization, sterilization, and heat recovery. Our PHEs are engineered for gentle product treatment and efficient heat transfer, critical for sensitive food products. For specific challenges like sticky fluids in candy manufacturing, specialized solutions are available to prevent buildup and ensure continuous operation.

What Role Do Heat Exchangers Play in Power Plants?

In power generation, heat exchangers are at the heart of thermal management, ensuring maximized energy conversion and minimized downtime. They are essential in steam power plants for condensing exhaust steam, in gas and coal-fired plants for flue gas heat recovery, and in nuclear facilities for isolating radioactive fluids while maintaining thermal transfer. Heating Formula offers robust gasketed and welded plate heat exchangers built to handle high pressures, fluctuating loads, and thermal stress in these demanding environments.

How are Heat Exchangers Utilized in Automotive & Transportation?

While often hidden, heat exchangers are critical in the automotive and transportation sectors for cooling hydraulic oil, tempering furnaces, and recovering heat from hot gases in manufacturing processes. The need for lightweight and efficient components in this industry is a key driver for advanced heat exchanger designs.

What are the Applications of Heat Exchangers in Manufacturing?

Manufacturing processes widely depend on heat exchangers for stabilizing systems, protecting machinery, and recovering energy. From heavy manufacturing (cooling hydraulic oil) to consumer goods (precise heating and cooling for injection molding), industrial heat exchangers ensure consistent product quality and reduced waste. Heating Formula offers a range of industrial heat exchanger types, from compact units to large-scale systems, designed for intense throughput and resistance to clogging.

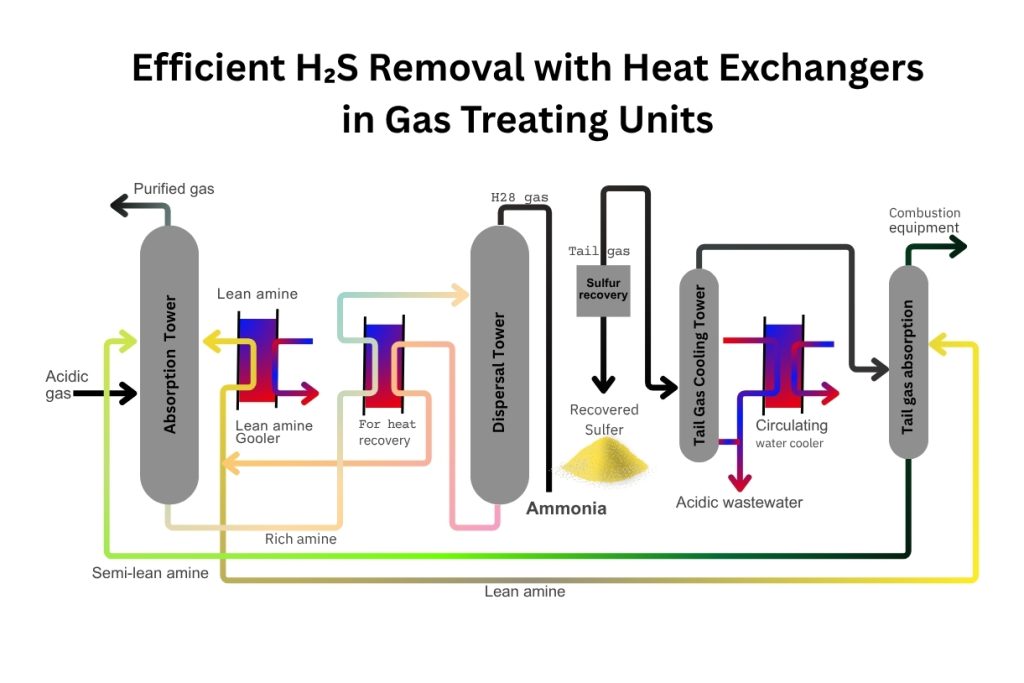

Why are Heat Exchangers Essential in the Oil & Gas Industry?

The oil and gas industry pushes heat exchangers to their limits, dealing with aggressive fluids, extreme temperatures, and high pressures. Applications include fluid-to-fluid transfer for stabilizing reaction temperatures and gas-to-gas processes for heat recovery from exhaust streams. Materials like titanium and high-grade stainless steel are crucial for resisting corrosion and fouling in these environments.

Assembly and Installation Guidelines

Proper assembly and installation are paramount for the safe and efficient operation of your Heating Formula PHE.

What Precautions Should Be Taken During Assembly?

- Safe Lifting: Always use appropriately sized shackles and rigging equipment when lifting the PHE, attaching them securely to the end plates. Never attach lifting slings to the port ferrules.

- Cleanliness: Ensure all plates, gaskets, and grooves are clean and free of contaminants before assembly.

- Plate Order: When reassembling, meticulously follow the original plate sequence to minimize the risk of leaks and ensure optimal performance. Each plate should be numbered during disassembly.

- Gasket Installation: Confirm the correct gasket type is used and that each gasket fits snugly within its groove. Ensure surfaces are dry and clean before attachment.

- Tightening: Gradually tighten all bolts in a cross-wise pattern, ensuring the movable plate remains parallel to the fixed plate. Monitor the tightening dimension (“a” value) to stay within the specified range on the nameplate.

How Should Pipe Connections Be Installed?

- Support Heavy Pipes: Ensure external support for heavy piping to prevent stress on the heat exchanger.

- Vents: Install vent valves at the highest points on both fluid sides to facilitate air removal during start-up.

- Flush Piping: Thoroughly flush all connecting pipes before attaching them to the PHE to prevent foreign debris from entering the unit.

- Flexible Connections: Consider installing flexible connections to absorb vibrations and accommodate plate pack displacement.

Commissioning and Operation

Starting up and operating your Heating Formula PHE correctly will ensure its long-term efficiency and prevent potential damage.

What are the Essential Steps for Commissioning?

- Pre-checks: Verify that all necessary equipment is installed and that the media and operating conditions align with the PHE’s design tolerances indicated on the nameplate.

- Prevent Water Hammer: Gradually open or close valves to avoid sudden pressure surges. Avoid rapid temperature changes if the ambient temperature has fluctuated significantly.

- Vent Air: Ensure vent valves are fully open during start-up to expel all air from the system, closing them only when fluid consistently flows out.

How to Operate Your Heat Exchanger Safely and Efficiently?

- Start-up Sequence: Generally, begin by flowing the less temperature-sensitive media first. For multi-section PHEs, ensure all sections are pressurized evenly.

- Daily Monitoring: Regularly record temperature and pressure data, ensuring they remain within the specified operational range.

- Flow Rate Adjustments: Make slow, gradual adjustments to flow rates to prevent sudden temperature and pressure variations.

- Leakage Inspection: Daily visual checks for external leakage around the unit or drip tray are crucial.

- Shutdown Procedure: Reverse the start-up sequence, slowly closing valves. For extended downtime, drain all fluids to prevent freezing or stagnation.

Maintenance for Long-Term Performance

Regular maintenance is vital for extending the lifespan and maintaining the efficiency of your Heatings Formula PHE.

What is Clean in Place (CIP) and When is it Used?

CIP is a method of cleaning the heat exchanger without disassembling it. It is effective for smaller units, frequent light cleaning, and when the cleaning agent is compatible with the scale and unit materials.

- Process: CIP involves circulating a chemical cleaning solution through the unit, typically flowing from bottom to top to ensure all surfaces are wetted. For multi-pass units, reverse flow may be required during the cleaning cycle.

- Benefits: Reduces downtime compared to manual cleaning and is convenient.

When is Manual Cleaning Necessary?

Manual cleaning provides a more thorough cleaning, reaching areas that CIP might miss, and is often necessary for severe fouling.

- Opening the Unit: Always ensure the unit is drained and cooled before opening. Record the tightening dimensions before loosening any bolts.

- Cleaning Plates: Plates can be cleaned while suspended on the carrying bar using a high-pressure washer or soft brush, or removed entirely for more thorough cleaning.

- Chemical Soaking: For stubborn scale, plates can be immersed in a chemical bath, ensuring the chemical is compatible with the plate material. Wear appropriate protective gear when handling chemicals.

Addressing Common Issues: Troubleshooting Your PHE

Even with proper operation and maintenance, issues can arise. Here’s a quick guide to common problems and their solutions. Heating Formula offers comprehensive support, including material selection, parts replacement, reconditioning, and performance audits.

Troubleshooting Leaks

- External Leakage (Gaskets Visible/Pushed Out):

- Possible Causes: Hydraulic hammering, gasket swelling/incompatibility, deformed gasket grooves, un-tightened plate pack, clogging, broken glue bond.

- Remedy: Re-gasket, upgrade to epoxy fastening, ensure gasket compatibility, check start-up procedures. Always follow operating manual for proper procedures.

- External Leakage (Gaskets Loose/Missing Pieces):

- Possible Causes: Gasket material degradation (age, high temperature, oxidants), improper gasket placement.

- Remedy: Replace gaskets with compatible material, ensure correct installation.

- Internal Leakage (Process Media Leaking into Utility Media):

- Possible Causes: Corrosion or fatigue cracking of plates.

- Remedy: Perform a hydro test to locate the leak, consider upgrading plate material or check for pressure spikes.

Troubleshooting Performance Issues

- High Pressure Drop or Reduced Thermal Performance (Cyclic Deviation):

- Possible Causes: Seasonal temperature variations or unstable processes.

- Remedy: Confirm parameters against original design, consider redesign or optimizing channel plate shear stress.

- High Pressure Drop or Reduced Thermal Performance (Gradual Deviation):

- Possible Causes: Accumulation of undesired substances (fouling), low shear stress on plate channels, operating conditions differing from design.

- Remedy: Perform chemical or mechanical cleaning, confirm flow rates, consider removing plates to increase shear stress or installing inline filters.

- High Pressure Drop or Reduced Thermal Performance (Immediate Deviation):

- Possible Causes: Particulate size exceeding pressing depth, foreign debris in stream.

- Remedy: Identify particulate size, backflush filters, or consider wider gap plates. Flush pipes before initial start-up.

- Uneven Temperature Distribution:

- Possible Causes: Uneven flow distribution due to operating conditions differing from design, or wrong design.

- Remedy: Redesign for more even flow, consider larger port size or adding parallel units.

Troubleshooting Damages

- Damages on Plates and Plate Packs (Deformations, Scratches, Rust, Snaking):

- Possible Causes: Mishandling during transport or on-site, normal wear and tear (rust).

- Remedy: Record damages, perform risk assessment, conduct leak test. Handle with care and use correct tools in the future.

FAQ Section

Q: How can I ensure the correct sizing of a plate heat exchanger for my application?

A: Proper sizing is critical for efficiency and longevity. Factors like desired temperature dynamics, flow rate, and operational limits must be considered. You can use our Heat Exchanger Calculator for accurate sizing, or consult with our experts for a tailored solution. For more details, refer to our blog post, “Essential Steps for Accurately Sizing a Plate Heat Exchanger.”

Q: What steps can I take to prevent fouling in my heat exchanger?

A: Preventing fouling involves good design practices, maintaining optimal fluid velocity, managing temperature differences, and potentially using chemical additives. Regular cleaning, including Chemical In Place (CIP) procedures, is crucial. You can learn more about this in our article on “Why Plate Heat Exchangers Save Energy for Our Industry.“

Q: Why is material selection important for heat exchangers, especially in corrosive environments?

A: Choosing the right material ensures the heat exchanger’s longevity and resistance to corrosion and fouling. For corrosive applications, materials like titanium, Hastelloy, or specialized stainless steels are essential. Our blog post “Titanium in Heat Exchangers” and “Why 254 SMO Is the Heat Exchanger’s Champion for Corrosive Applications” delve deeper into this topic.

Q: How do plate heat exchangers contribute to energy savings?

A: Plate heat exchangers are highly efficient due to their large heat transfer surface area and ability to promote turbulent flow, leading to lower heat loss and reduced energy consumption. Their compact design also minimizes installation and operational costs. Explore this further in “Why Plate Heat Exchangers Save Energy for Our Industry.”

Q: What are the benefits of choosing Heating Formula over other manufacturers?

A: Heating Formula, a heat exchanger manufacturer and supplier in Turkey, offers high-quality plate heat exchangers and compatible spare parts with OEM compatibility for brands like Alfa Laval, Sondex, APV SPX, Funke, Schmidt, Vicarb, Gea, and Tranter. Our advanced thermal hydraulic designs prioritize efficiency, reliability, and ease of maintenance, providing long-term value. Our commitment to readily available spare parts and global support network sets us apart. You can explore our product range further through our GPHE Selection and GPHE Spare Parts sections.

Troubleshooting Leaks Between Heat Transfer Plates in Plate Heat Exchangers (PHEs)

Experiencing leaks between heat transfer plates in your plate heat exchanger? Use this troubleshooting guide to identify potential causes and take the right corrective actions.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Leaks between heat transfer plates | Incorrect plate pack tension (tensioning dimension) | Verify and adjust the tensioning dimension according to the specifications on the unit’s nameplate. |

| Excessive operating pressure | Confirm that the system pressure does not exceed the maximum rating listed on the nameplate. Adjust as needed. | |

| Operating temperature out of range | Ensure operating temperatures are within the specified limits indicated on the nameplate. | |

| Gaskets improperly seated | Open the unit and realign or refit the gaskets on the heat transfer plates. | |

| Gaskets contaminated with dirt or debris | Disassemble the PHE and clean the gaskets thoroughly. | |

| Gaskets are worn, hardened, or damaged | Replace defective gaskets with new ones that meet manufacturer specifications. |

Maintenance Tip: Regular inspection and proper maintenance of gaskets and operating conditions can help prevent leaks and extend the service life of your plate heat exchanger.

Troubleshooting Plate Heat Exchanger (PHE) Issues

If you’re experiencing performance or leakage problems with your plate heat exchanger, use this guide to identify potential issues, their causes, and how to resolve them effectively.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Leaks between heat transfer plates and frames, reinforcement plates, or intermediate plates | Incorrectly seated plate and frame gaskets | Open the PHE and properly seat the plate and frame gaskets. |

| Soiled plate and frame gaskets | Open the PHE and clean the gaskets thoroughly. | |

| Defective plate and frame gaskets | Open the PHE and replace the damaged gaskets with new ones. | |

| Leaks between frame connection and pipework | Excessive load from connected pipework | Reduce pipework loads to the values permitted by the manufacturer. |

| Improperly seated gasket | Loosen the frame connection and correctly seat the gasket. | |

| Contaminated gasket | Loosen the connection and clean the gasket surface. | |

| Damaged gasket | Loosen the connection and replace the defective gasket. | |

| Loose flange connection | Inspect the gasket and retighten the connection evenly if necessary. | |

| Damaged heat transfer plates | Over-tightening of the plate pack (tensioning dimension below minimum) | Replace any defective heat transfer plates and adjust tensioning correctly. |

| Material corrosion of the heat transfer plates | Review design and operational parameters to ensure compatibility and prevent corrosion. | |

| Damage to plates at the beginning or end of PHE | Incorrect earthing during welding on special pipe connections | Replace the damaged heat transfer plates and follow proper grounding procedures when welding. |

Pro Tip: Consistent inspection of gaskets, tightening settings, and operating conditions helps maintain peak efficiency and avoid costly downtime in plate heat exchanger systems.

Troubleshooting Heat Exchanger Performance Issues

If your plate heat exchanger (PHE) is underperforming, review the following common causes and corrective actions:

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Reduced heat transfer | Deposits on the heat transfer plates | Clean the heat transfer plates according to PHE Cleaning procedures. |

| Operation or flow media differing from design case | Verify that system operation and fluid media match the original design specifications. | |

| Excessive pressure loss | Flow obstruction due to plugged manifold gaps | Clean the heat transfer plates according to PHE Cleaning guidelines. |

| Incorrect installation of heat transfer plates | Check the installation order using the circuit diagram provided by the manufacturer. | |

| Mismatch between operation and design data | Review and confirm that the PHE is operating within its design parameters. |

PHE Cleaning Guidelines

To maintain optimal performance, follow manufacturer-recommended cleaning procedures regularly. Cleaning methods typically include:

- Manual or chemical cleaning depending on the type of deposit

- Regular inspection and cleaning of plates and gaskets

- Using only approved cleaning agents to prevent material damage

Performance Tip: Routine monitoring and timely cleaning of heat exchanger plates are critical to avoiding costly downtime and preserving system efficiency.

Recommended Cleaning Agents for Heat Exchanger Plates

Using the right cleaning agents for your plate heat exchanger (PHE) ensures optimal thermal efficiency and prolongs equipment lifespan. The table below outlines suitable cleaning agents, their effectiveness, and usage guidelines.

| Cleaning Agent Type | Compatible Plate Material | Effective Against | Recommended Temperature | Concentration | Cleaning Method |

|---|---|---|---|---|---|

| Water-based degreaser | All | Mineral oil | 25 – 40°C | 2 – 6% | Immersion |

| Descaling agent | All | Inorganic salt fouling | 25 – 40°C | %10 | Rinse / Immersion |

| Caustic cleaner | Stainless steel | Organic and inorganic scaling | 50 – 80°C | 0.5 – 3% | CIP (Clean-In-Place) |

Note: Always verify chemical compatibility with plate and gasket materials before use. Follow manufacturer guidelines for cleaning duration and safety protocols.

Optimizing Plate Heat Exchanger Cleaning: CIP vs. Manual Methods

Maintaining the efficiency of your Plate Heat Exchanger (PHE) is crucial for optimal performance and longevity. Regular cleaning prevents fouling, scaling, and pressure loss. This guide explores two primary cleaning methods: Clean in Place (CIP) and Manual Cleaning, offering insights and best practices for each.

CIP: Clean in Place – Automated Efficiency for PHEs

What is CIP (Clean in Place)? CIP, or Clean in Place, is an automated cleaning method for Plate Heat Exchangers, allowing for system cleaning without disassembly. This technique uses circulating chemical solutions to dissolve and remove deposits, making it a convenient and economical option for routine maintenance.

When is CIP Most Effective for your PHE? CIP delivers superior results under specific conditions:

- Compact PHE Design: Ideal for relatively small plate heat exchanger units.

- Frequent & Short-Term Cleaning: Perfect for routine, preventive maintenance schedules.

- Dissolvable Scale: Most effective when the fouling or scale can be easily dissolved by chemical cleaning agents, without harming the PHE plates or gaskets.

Expert CIP Cleaning Tips for Plate Heat Exchangers:

- Chemical Compatibility is Key: Always consider the chemical properties of both your process media and the cleaning agent. This prevents adverse reactions from any residual chemicals after draining the system.

- Ensure Full Surface Wetting: For comprehensive cleaning, introduce the CIP solution from the bottom up to ensure all internal surfaces are thoroughly wetted. For multi-pass units, reverse the flow direction for at least half of the cleaning duration to reach all channels.

- Reverse Flushing for Coarse Particles: If your flow media contains coarse dirt, consider reverse flushing as an alternative or supplementary cleaning method. Briefly reversing the flow direction helps dislodge and remove stubborn particles from the manifold channels, preventing blockages.

Manual Cleaning: The Deep Clean for Optimal PHE Performance

While CIP offers convenience, the complex corrugated structure of PHE plates means “no dead corner cleaning” is rarely achieved solely through CIP. Manual cleaning, though more labor-intensive, guarantees a pristine Plate Heat Exchanger, restoring it to “like-new” condition.

When to Choose Manual PHE Cleaning: Manual cleaning is recommended for:

- Severe scaling or stubborn fouling that CIP cannot fully remove.

- Detection of leaks during PHE operation, indicating potential gasket or plate issues requiring closer inspection.

- Achieving the most thorough clean possible for maximum efficiency.

I. Safely Opening Your Plate Heat Exchanger

Critical Precautions Before Opening:

- Drain All Fluids: Never open the PHE before completely draining all fluids from the system.

- Allow Cooling: Ensure the PHE temperature has cooled down to a safe level before proceeding.

Step-by-Step Opening Procedure:

- Record “a” Value: Before loosening any bolts, measure and meticulously record the actual “a” value (tensioning dimension) at the top, middle, and bottom sections on both sides of the PHE. This measurement is vital for correct reassembly.

- Maintain Bolts & Bar: If bolts and the carrying bar haven’t been maintained, clean and grease them. This ensures easy loosening and prevents damage during the process.

- Diagonal Bolt Loosening: Loosen the tightening bolts diagonally and equally. This ensures the movable plate opens in a parallel motion, preventing stress on the plates.

- Hydraulic Wrench for Large Units: For exceptionally large or numerous plates, a hydraulic wrench may be necessary. Use it to slightly tighten 4 or 6 diagonal bolts, then loosen the remaining bolts.

- Careful Bolt Removal: Systematically remove the bolts one by one.

- Gentle Plate Separation: Slowly push the movable plate until the plates are loose enough to detach from each other.

- Initial Inspection: Push aside the plate pack and visually inspect the level of fouling and scaling. Check plates on all sections (single or multi-section units).

II. Cleaning Plates Without Removal

If the fouling condition is mild and allows, you can clean the plates while they remain hanging on the frame:

- High-Pressure Flushing: Use a high-pressure hydraulic cleaner to flush the plates.

- Control Plate Spacing: Carefully control the space between plates during cleaning to prevent them from falling out.

III. Cleaning Removed Plates for Deep Restoration

For severe scaling or confirmed leaks, removing plates for a thorough wash is essential:

- Number Plates: Before detaching, number all plates to ensure correct reassembly order.

- Open Plate Pack: Let the pressure plate glide along the carrying bar, then stack the plates neatly on a protective pad (e.g., corrugated paper).

- Gasket Removal: Gently detach all gaskets from the plates.

- Initial High-Pressure Wash: Use a high-pressure hydraulic cleaner to wash off as much scale as possible.

- Chemical Cleaning (If Needed): If scale persists after the high-pressure wash, consider chemical cleaning.

- Consult Experts: Always consult your technical department or the manufacturer for suitable cleaning agents for your specific plate material.

- Safety First: When working with aggressive chemicals, wear appropriate personal protective equipment (goggles, rubber gloves, protective clothing).

- Immersion Process: Prepare a basin of suitable size and fill it with the cleaning agent. Immerse the plates. Refer to cleaning agent guidelines for recommended temperature, concentration, and immersion time.

Sources

- Jalili, B., Aghaee, N., Jalili, P., & Ganji, D. D. (2022). Novel usage of the curved rectangular fin on the heat transfer of a double-pipe heat exchanger with a nanofluid. Case Studies in Thermal Engineering, 35, 102086.

- Kaur, I., & Singh, P. (2021). State-of-the-art in heat exchanger additive manufacturing. International Journal of Heat and Mass Transfer, 178, 121600.

- Rooholamini, S., Ghorbani, B., & Ebrahimi, A. (2021). Introducing a novel hybrid system for cogeneration of liquefied natural gas and hot water using ejector-compression cascade refrigeration system (energy, exergy, pinch and sensitivity analyses). Applied Thermal Engineering, 196, 117283.

- Stehlík, P., & Wadekar, V. V. (2002). Different Strategies to Improve Industrial Heat Exchange. Heat Transfer Engineering, 23(6), 36–48.