What is a Heat Exchanger?

Heat exchangers are ubiquitous in modern industry, silently playing a pivotal role in countless processes that shape our daily lives. From the air conditioning that cools our homes to the power plants that light our cities, these ingenious devices are responsible for efficiently transferring thermal energy from one fluid to another. But what exactly are they, and how did they become such indispensable components?

A Journey Through Time: The Genesis of Heat Exchange Technology

The fundamental principle of heat transfer has been understood for centuries, but the earliest recognizable heat exchange devices emerged with the Industrial Revolution. Imagine the early steam engines, crude yet revolutionary, where water was heated to produce steam. These rudimentary boilers were, in essence, the ancestors of modern heat exchangers, facilitating the transfer of heat from a combustion source to water. As industries grew and processes became more complex, the need for more controlled and efficient heat management became paramount. Early iterations were often simple coils or tanks, but the quest for improved performance, reduced footprint, and greater versatility led to the development of increasingly sophisticated designs. The evolution of heat exchangers has been a continuous story of innovation, driven by the ever-present need to optimize energy use and enhance industrial processes.

Diving Deep: Exploring the Diverse World of Heat Exchanger Types

Shell and Tube

Brazed Plate Heat Exchanger

The world of heat exchangers is vast and varied, with designs tailored to a multitude of applications and operational demands. While the core function remains the same – transferring heat between fluids – the methods by which they achieve this can differ significantly. Let’s explore some of the most common types you’ll encounter:

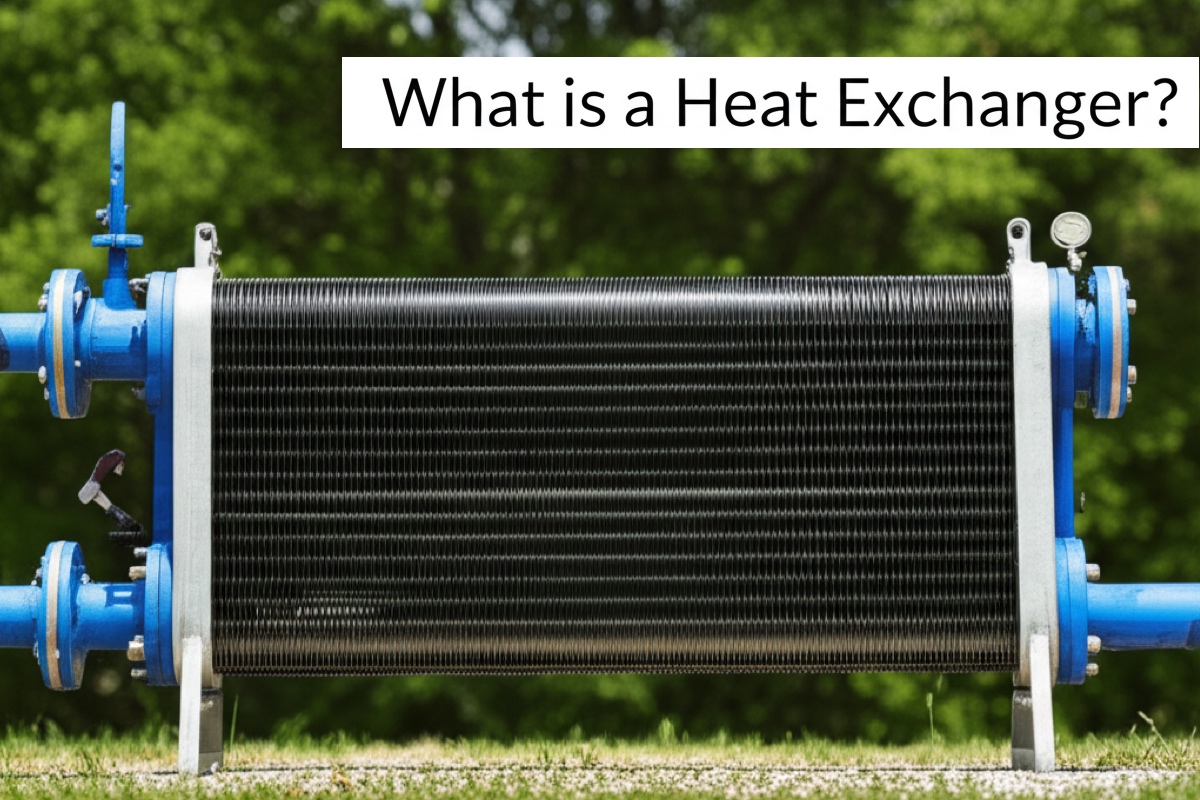

1. The Workhorse of Industry: Shell and Tube Heat Exchangers

When you picture an industrial heat exchanger, chances are you’re envisioning a shell and tube design. These robust units consist of a cylindrical outer shell containing a bundle of smaller tubes. One fluid flows through these tubes, while the other fluid flows through the shell, around the outside of the tubes. This design allows for a large heat transfer surface area within a contained space.

Why are Shell and Tube Heat Exchangers so prevalent?

- Durability and High Pressure/Temperature Capability: These exchangers are renowned for their rugged construction, capable of handling extremely high pressures and temperatures. This makes them a go-to choice in demanding environments like power plants, oil refineries, and chemical processing facilities.

- Long Service Life: Their robust build generally translates to a long operational lifespan, making them a reliable investment.

- Versatility: They can be configured for various flow arrangements (parallel flow, counterflow, crossflow) and are widely used for everything from preheating to steam generation.

However, traditional shell and tube units can be large, requiring significant installation and maintenance space, especially when the tube bundle needs to be removed for cleaning.

2. Compact and Adaptable: Plate Heat Exchangers

In contrast to the hefty shell and tube designs, plate heat exchangers (PHEs) offer a more compact and flexible solution. These units are made up of a series of thin, corrugated plates pressed together, creating channels through which fluids flow. The alternating channels allow for efficient heat transfer between the hot and cold fluids.

What makes Plate Heat Exchangers stand out?

- High Efficiency: Due to their large surface area and ability to promote turbulent flow, plate heat exchangers boast high heat transfer efficiency, often exceeding that of shell and tube units.

- Compact Footprint: They require significantly less space for a given heat transfer duty, making it ideal for installations where floor space is at a premium.

- Easy Maintenance and Scalability: Plate heat exchangers are designed for easy disassembly, allowing for quick cleaning and replacement of individual plates and gaskets. Their modular nature also means capacity can be easily increased or decreased by simply adding or removing plates.

- Reduced Fouling Tendency: The turbulent flow within the plate channels helps to minimize fouling, leading to longer operational periods between cleanings.

3. Specialty Solutions: Beyond the Mainstream

Beyond these two primary types, a range of specialized heat exchangers caters to specific industrial needs:

- Welded Block Heat Exchangers: These are fully welded, compact units designed to handle aggressive fluids and very high temperatures without the need for gaskets. They offer durability and low maintenance in extreme conditions.

- Shell and Plate Heat Exchangers: A hybrid design combining features of both shell and tube and plate exchangers, offering high pressure capability and thermal efficiency in a smaller footprint.

- Spiral Heat Exchangers: Constructed from two plates wound together to create a concentric spiral, these are excellent for handling challenging fluids like sludges or slurries, and highly viscous media. Their single-channel design creates high shear rates, contributing to a self-cleaning effect and minimizing clogging.

- Brazed Plate Heat Exchangers: These compact units consist of stainless steel plates brazed together, offering high performance and excellent heat and pressure resistance. They are often used in refrigeration cycles and for heating/cooling various industrial fluids.

- Air-Cooled Heat Exchangers: Also known as air fin coolers, these use ambient air to cool fluids, eliminating the need for water-based cooling systems.

Avoiding Common Heat Exchanger Missteps: A Proactive Approach

Plate and Shell Heat Exchanger

Shell and coil Heat Exchanger

Even with the right heat exchanger in place, operational issues can arise if proper care and attention aren’t given. Here are some common mistakes and how to steer clear of them:

- Ignoring Pressure Drop: A sudden increase in pressure drop is often a red flag, indicating fouling or a blockage within the unit. Promptly investigating and addressing these deviations is crucial to prevent further issues and potential equipment failure.

- Neglecting Regular Maintenance: Just like any critical equipment, heat exchangers require consistent maintenance to perform optimally. Skipping scheduled servicing can lead to reduced efficiency and unexpected breakdowns. Regular cleaning and inspection are vital.

- Lack of Spare Parts: Being caught without essential spare parts during a breakdown can lead to costly downtime. Keeping a readily available stock of critical components like gaskets and plates can significantly reduce recovery time.

- Improper Assembly: Correct assembly is paramount for optimal performance. Incorrect plate alignment or improper tightening can lead to reduced efficiency and leakage. Always follow the manufacturer’s instructions diligently.

- Choosing the “Best” Material Over the “Right” Material: It’s tempting to opt for the most expensive or seemingly “best” material, but suitability for your specific process fluids and operating conditions is far more important. An over-specced material can lead to unnecessary costs.

- Oversizing the Unit: While a cautious approach, oversizing a heat exchanger can lead to increased initial costs and a larger footprint than necessary. Understanding the normal operational range and optimizing for everyday efficiency is key.

Where Do Heat Exchangers Find Their Purpose? Diverse Applications Across Industries

Heat exchangers are the silent workhorses in nearly every industrial sector, enabling processes that range from simple heating and cooling to complex energy recovery.

- Refrigeration: From commercial grocery displays to industrial cold storage, heat exchangers are essential for absorbing and releasing heat, ensuring product freshness. Compact plate heat exchangers are particularly well-suited for these temperature-sensitive applications.

- Power Generation: In power plants, they manage the steam cycle, preheat feedwater, and cool auxiliary systems, maximizing energy conversion and minimizing downtime. This includes gas, coal, and nuclear power facilities, where materials must withstand extreme conditions.

- HVAC and District Heating/Cooling: They are fundamental to maintaining comfortable climates in buildings and distributing thermal energy efficiently across urban networks.

- Chemical Processing: Dealing with corrosive fluids and aggressive reactions, chemical heat exchangers require specialized materials like titanium or stainless steel, enabling precise temperature control and safeguarding equipment.

- Food and Beverage: From pasteurization and sterilization to chilling and heating, heat exchangers ensure product quality, extend shelf life, and maintain hygienic standards. Advanced technologies like infusion UHT systems (which utilize heat exchange principles) are revolutionizing dairy processing by quickly and gently heating products to achieve extended shelf life without compromising taste or nutritional value.

- Industrial Manufacturing: Across various manufacturing sectors, they are crucial for cooling hydraulic oil, tempering furnaces, and recovering waste heat, contributing to stable systems and reduced energy consumption.

- Marine Industry: On vessels, heat exchangers handle critical cooling duties for engines and auxiliary systems, often operating with challenging media like seawater. Proactive maintenance is vital to avoid costly operational disruptions.

Sourcing Quality Materials for Your Heat Exchanger

The performance and longevity of any heat exchanger heavily depend on the quality of its components and the materials from which they are manufactured. For critical parts like plates and gaskets, sourcing from reliable suppliers is paramount. Materials are chosen based on their thermal conductivity, corrosion resistance, pressure and temperature tolerance, and compatibility with the fluids being processed. Common materials include various grades of stainless steel, titanium, and high-nickel alloys, each selected for specific challenging environments. For instance, titanium is often preferred for applications involving seawater due to its excellent corrosion resistance.

Heating Formula supplies a comprehensive range of heat exchangers and spare parts, all manufactured to be equivalent to original equipment manufacturer (OEM) standards. From robust shell and tube designs to flexible plate heat exchangers and specialized components, you can explore detailed information and choose the best fit for your requirements. If you need assistance with selection, you can utilize our heat exchanger calculator or browse our selection of gasketed plate heat exchanger spare parts. For specific product selection assistance, including gasketed plate heat exchanger selection, don’t hesitate to contact us.

Troubleshooting Common Heat Exchanger Problems

Even with the best equipment and proactive maintenance, issues can occasionally arise. Here’s a quick guide to some common problems and their potential solutions:

- Reduced Heat Transfer Performance:

- Possible Cause: Fouling on heat transfer surfaces.

- Remedy: Disassemble and thoroughly clean the heat transfer plates. Consider chemical cleaning (CIP) for stubborn deposits.

- Increased Differential Pressure or Decreased Flow Rate:

- Possible Cause: Clogging of port holes or narrowed plate gaps due to fouling.

- Remedy: Clean the unit. For gasketed plate heat exchangers, re-tightening the plate pack might also help, ensuring it doesn’t go below the minimum length.

- Fluid Leaking to the Outside:

- Possible Cause: Aged or deteriorated gaskets, foreign material on sealing surfaces, or incorrect gasket placement.

- Remedy: Replace damaged gaskets with new ones. Inspect for and remove any foreign materials. Ensure gaskets are correctly seated in their grooves. External leakage can also indicate hydraulic hammering or an un-tightened plate pack.

- Intermixing of Hot and Cold Media:

- Possible Cause: Cracks or pinholes in the heat transfer plates due to corrosion or fatigue.

- Remedy: Replace damaged plates. This is a critical issue that requires immediate attention to prevent product contamination.

- Plate Deformation:

- Possible Cause: Excessive tightening, gasket expansion, or water hammering (sudden pressure shocks in the system).

- Remedy: Replace deformed plates and implement measures to prevent water hammering during operation. Ensure correct tightening length during assembly.

Regular inspection and a good understanding of these common issues can help minimize downtime and extend the life of your heat exchangers.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of a heat exchanger?

A1: A heat exchanger’s primary function is to efficiently transfer thermal energy from one fluid (liquid or gas) to another without direct mixing of the fluids.

Q2: What is the main difference between a shell and tube heat exchanger and a plate heat exchanger?

A2: A shell and tube heat exchanger uses a bundle of tubes enclosed within a shell, while a plate heat exchanger uses multiple thin, corrugated plates to create fluid channels. Shell and tube units are generally more robust for high-pressure/temperature applications, while plate exchangers offer higher efficiency and a more compact design for many duties.

Q3: How can I prevent fouling in my heat exchanger?

A3: Fouling can be minimized through proper fluid treatment, optimizing flow rates to maintain turbulence, and implementing regular cleaning procedures like Cleaning-in-Place (CIP) or mechanical cleaning. Selecting plates with patterns that discourage deposits can also help.

Q4: What happens if a heat exchanger is improperly sized?

A4: Improper sizing can lead to inefficiencies, where the unit doesn’t meet heat transfer demands, or increased costs due to oversizing. It can also cause operational shortcomings, affecting product quality and consistency.

Q5: How often should I perform maintenance on my heat exchanger?

A5: The maintenance interval depends on the operating conditions and the type of fluids used. However, regular inspection and cleaning are recommended to ensure optimal performance and extend the unit’s lifespan. For new units, an initial inspection after about a year can help establish an appropriate maintenance cycle. Proactive replacement of consumables like gaskets at recommended intervals is also crucial.