Why Are Shell and Tube Heat Exchangers Essential for the Hydrogen Economy?

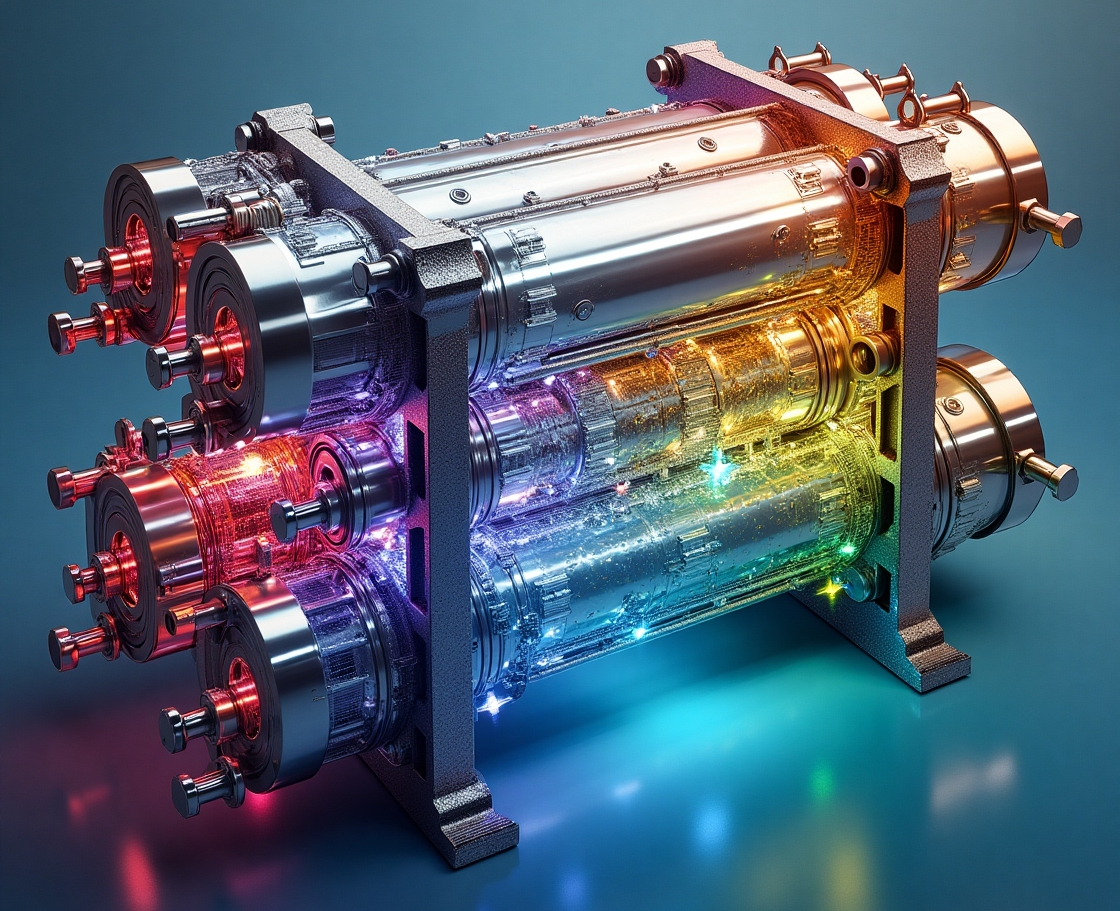

The race to achieve net-zero emissions has put hydrogen in the spotlight. This clean fuel can power industries, vehicles, and even cities without releasing carbon dioxide. But producing, storing, and transporting hydrogen isn’t simple—it requires technology that can handle extreme temperatures, corrosive environments, and high-pressure systems. Enter the shell and tube heat exchanger, a century-old engineering marvel that’s finding new life in the hydrogen revolution. Let’s explore why this workhorse of thermal management is critical for a sustainable future.

What’s the History Behind Shell and Tube Heat Exchangers?

Invented in the late 1800s, shell and tube heat exchangers became industrial staples by the 1920s. Their simple design—a bundle of tubes enclosed in a cylindrical shell—allowed factories to transfer heat between fluids efficiently. Over time, they evolved to handle tougher jobs, from nuclear reactors to oil refineries. Today, they’re being re-engineered for hydrogen systems, proving that even classic designs can adapt to cutting-edge challenges.

How Do Shell and Tube Exchangers Differ From Other Types?

Not all heat exchangers are built the same. While gasketed plate models (like those we offer at Heating Formula) excel in compact spaces, shell tube exchangers dominate high-pressure and high-temperature applications. Their robust metal construction resists corrosion, and their modular design allows easy repairs—a lifesaver in hydrogen plants where downtime costs millions.

What Challenges Do Hydrogen Systems Pose?

Hydrogen might be light, but working with it is heavy-duty. Here’s where traditional equipment falls short:

1. Extreme Cold: Can Heat Exchangers Handle -253°C?

Storing hydrogen as a liquid slashes its volume by 800x. But chilling it to -253°C demands heat exchangers that won’t crack like glass. Standard materials become brittle, but specialized shell & tube type heat exchangers with stainless steel or aluminum alloys thrive in cryogenic hell.

2. Hydrogen Embrittlement: Will Metals Crumble?

Hydrogen atoms are tiny—they sneak into metal lattices, causing cracks and leaks. This “embrittlement” ruins most equipment. However, shell and heat exchanger designs using hydrogen-resistant alloys (like Inconel 625) prevent this decay, ensuring decades of safe operation.

3. Efficiency: Can Waste Heat Be Captured?

Electrolysis, the process of splitting water into hydrogen, wastes up to 30% energy as heat. Modern shell tube exchangers recover this heat, boosting efficiency to 85%—a game-changer for green hydrogen’s cost.

How Are Shell and Tube Exchangers Solving These Problems?

Innovation is turning these veterans into hydrogen heroes:

1. Cryogenic Champions

Liquid hydrogen plants now use spiral-wound shell and tube heat exchangers with ultra-thin tubes. These maximize surface area for faster cooling while withstanding thermal shocks. Companies like Air Liquide have slashed liquefaction costs by 15% using this tech.

2. Armor Against Embrittlement

New nickel-based coatings act like armor for tube surfaces. Paired with hydrogen-trapping additives in the metal, they extend exchanger lifespans from 5 to 20+ years. Heating Formula’s partners now test these coatings in pilot hydrogen hubs.

3. Printed Circuit Heat Exchangers (PCHEs): The Hybrid Future

By etching fluid channels into metal plates, PCHEs offer shell and tube-like durability with 10x higher efficiency. They’re ideal for hydrogen compression stations, where space is tight but pressures exceed 1000 bar.

Who’s Using Shell and Tube Exchangers Successfully?

Case Study 1: Siemens’ Hydrogen Highway

Siemens Energy’s H2 compressors use shell and tube heat exchangers to cool hydrogen from 300°C to 50°C in seconds. This prevents overheating in pipelines, allowing Germany to blend 20% hydrogen into its gas grid by 2030.

Case Study 2: Ammonia Cracking in Japan

Japan imports hydrogen as ammonia (NH3). At receiving terminals, shell tube exchangers heat ammonia to 650°C, cracking it into hydrogen. Waste heat from the reaction preheats incoming ammonia, cutting energy use by 40%.

What’s Holding Back Hydrogen-Ready Heat Exchangers?

Cost remains a hurdle. A single cryogenic shell & tube type heat exchanger can cost $500k—10x more than standard models. However, startups like H2X are 3D-printing exchangers with internal baffles that slash costs by 60%. Governments are also funding R&D; the U.S. DOE recently granted $28M for hydrogen-compatible heat tech.

How Can Engineers Prepare for the Hydrogen Shift?

Start by auditing existing shell and heat exchanger systems. Can they handle hydrogen blends? Upgrading materials or adding coatings might be cheaper than replacements. For new projects, consult experts to balance upfront costs with lifecycle savings. Remember, hydrogen-ready designs often qualify for green subsidies.

Need Spare Parts for Your Hydrogen Project?

At Heating Formula, we stock specialized gaskets, tubes, and plates for shell and tube heat exchangers in hydrogen service. Browse our cryogenic-ready parts designed for -253°C to 300°C operation.

Final Word: The Heat Exchanger’s Hydrogen Moment

From green steel to fuel cell trucks, hydrogen’s potential is limitless—if we can manage its heat. With their rugged build and adaptability, shell and tube heat exchangers are poised to be the backbone of this new economy. The question isn’t whether they’ll be used, but how quickly manufacturers can scale hydrogen-ready models. For engineers, the message is clear: Master thermal management, and you’ll hold the key to the hydrogen future.