The Hidden Formula That Runs Your World (And How to Master It)

It starts with a tremor.

A subtle vibration in the machinery. A gauge a few degrees off. A fractional drop in output. It’s the kind of thing most people would miss. The kind of thing our plant manager, let’s call him Dave, noticed but dismissed. “It’s just the system settling,” he thought, logging it as a minor fluctuation. A rounding error in a massive industrial symphony.

But this rounding error was a symptom of a deeper truth, an invisible law that governs efficiency, from the heart of a power plant to the smartphone in your pocket. Dave’s rounding error cascaded. The minor fluctuation was a sign of fouling, a slow clogging of the industrial arteries. Efficiency dipped further. Pumps worked harder, consuming more energy just to stand still. Three months later, the tremor became a shutdown. The cost wasn’t just in repairs; it was in lost production, wasted energy, and a frantic scramble for emergency parts—a financial nightmare born from a problem everyone saw but no one truly understood.

Dave’s mistake wasn’t a failure of oversight. It was a failure of imagination. He saw a machine; he failed to see the current of energy flowing through it.

The Unseen Architecture of Energy

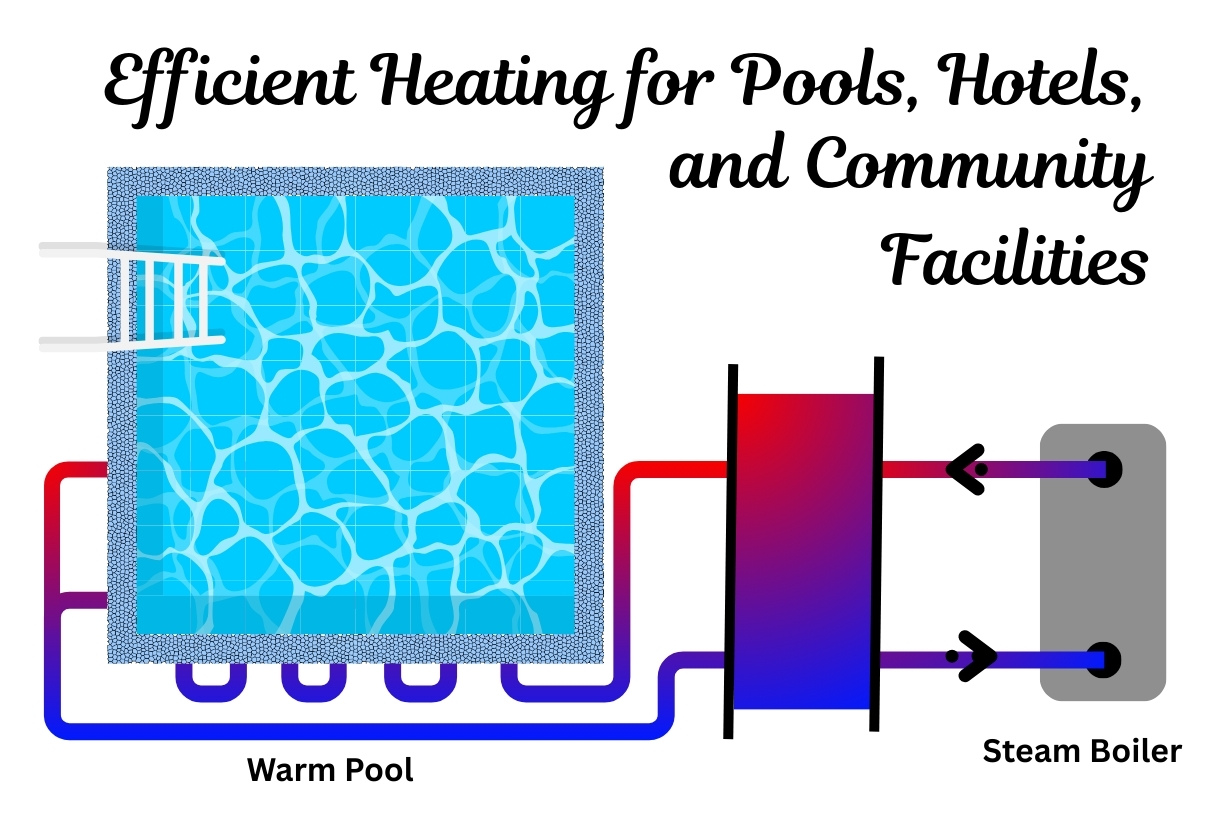

We are surrounded by monumental acts of engineering. We celebrate the towering structures, the powerful engines, the visible feats of force. Yet, the quiet, revolutionary work often happens in the spaces between—in the elegant, unseen transfer of thermal energy. This is the domain of the heat exchanger, a device so fundamental it’s easy to overlook, yet so critical that without it, modern industry would grind to a halt.

What exactly is a heat exchanger? At its core, it’s a master negotiator, persuading heat to move from where it isn’t wanted to where it can be put to work. This process isn’t just about nuts and bolts; it’s about mastering a fundamental formula for efficiency. It’s not a secret equation locked in a vault, but a principle hiding in plain sight, governed by what engineers call the Overall Heat Transfer Coefficient (U-Value). Think of the U-Value as a universal efficiency score. A higher score means your system is an A+ student, transferring heat with minimal effort and waste. A low score, like in Dave’s case, signals a struggling system, bleeding energy and money.

Improving that score—mastering the heating formula—isn’t about adding more brute force. It’s about getting smarter.

The Real Heating Formula: More Than Just an Equation

The true “heating formula” is a philosophy built on three pillars: elegant design, precise application, and long-term resilience. Getting this right is the difference between a system that merely functions and one that creates a powerful competitive advantage.

1. Elegant Design: The Power of the Plate

For decades, the industry standard was the colossal shell-and-tube heat exchanger—a reliable, yet often bulky and inefficient, workhorse. But as industries evolve, the demand for smarter, more agile solutions has grown. Enter the Gasketed Plate Heat Exchanger (GPHE). Instead of a massive shell, a GPHE uses a series of pressed corrugated plates. This ingenious design creates a huge surface area in a remarkably small footprint, a principle that leading institutions like Energy.gov recognize as crucial for modern energy efficiency.

This isn’t just an incremental improvement; it’s a leap forward. The turbulent flow created by the plates is far more efficient at transferring heat than the flow in a traditional shell-and-tube unit. This means you can achieve your heating or cooling targets faster and with significantly less energy—a direct boost to your bottom line and a core reason why plate heat exchangers save energy for our industry. For those ready to move beyond outdated technology, a thoughtful GPHE selection is the first step toward mastering the formula.

2. Precise Application: The Peril of “Good Enough”

An improperly sized heat exchanger is an engine of inefficiency. Too large, and you’ve wasted capital on oversized equipment that may perform poorly at your actual operating conditions. Too small, and your system will constantly struggle, creating bottlenecks and driving up energy consumption. It’s the industrial equivalent of wearing shoes three sizes too big—clumsy, wasteful, and guaranteed to cause problems down the line.

Precision is paramount. This is where modern tools meet timeless engineering principles, like those cataloged by the Engineering Toolbox. Accurately sizing a plate heat exchanger requires a deep understanding of your specific operational parameters—flow rates, temperatures, fluid properties, and allowable pressure drop. It’s a complex calculation, but one that pays dividends in performance and longevity. Thankfully, tools like a dedicated heat exchanger calculator can demystify the process, turning complex variables into actionable specifications. This is one of the most essential steps for accurately sizing a plate heat exchanger.

3. Long-Term Resilience: The Hidden Cost of a Weak Link

Dave’s story wasn’t about a catastrophic failure of a massive component. It began with the slow degradation of a small, overlooked part. A heat exchanger is a system, and a system is only as strong as its weakest link. Gaskets perish. Plates corrode. In the demanding world of industrial applications, especially those involving corrosive materials, the choice of materials is not a minor detail—it’s a strategic decision.

This is where advanced materials like Titanium and 254 SMO become champions, offering unparalleled resistance in corrosive applications. But resilience also comes from maintenance and having access to the right components when you need them. As a leading manufacturer and supplier, Heating Formula provides not just complete systems but also high-quality GPHE spare parts with OEM compatibility for major brands like Alfa Laval, Sondex, APV SPX, Funke, and more. Ensuring you have the right parts on hand transforms maintenance from a reactive panic into a proactive strategy, preventing a small issue from becoming a costly shutdown. Before you buy a heat exchanger, considering the availability and quality of its spare parts is a crucial piece of the puzzle.

Stop Searching for Silver Bullets

We are conditioned to look for the next big thing, the revolutionary technology that will change everything. But true, sustainable efficiency rarely comes from a single silver bullet. It comes from mastering the fundamentals. It’s found in the elegant dance of molecules, the precise calibration of systems, and the relentless pursuit of losing less.

The heating formula isn’t a product you can buy off a shelf. It’s a mindset. It’s the discipline to look past the obvious and pay attention to the subtle, powerful forces that truly drive your operations. It’s understanding that the biggest gains often come from optimizing the small, unseen connections within the system. For a deeper dive into these systems, the manual and application guide for heat exchangers offers a comprehensive resource.

So, the next time you walk through your facility, don’t just look at the machines. Look for the invisible currents of energy they depend on. Ask yourself: What is our heating formula? And what small tremor, what rounding error, are we currently ignoring?