Critical Heat Exchanger Components for Extreme Service: Materials, Performance, and Sourcing for Purchasers

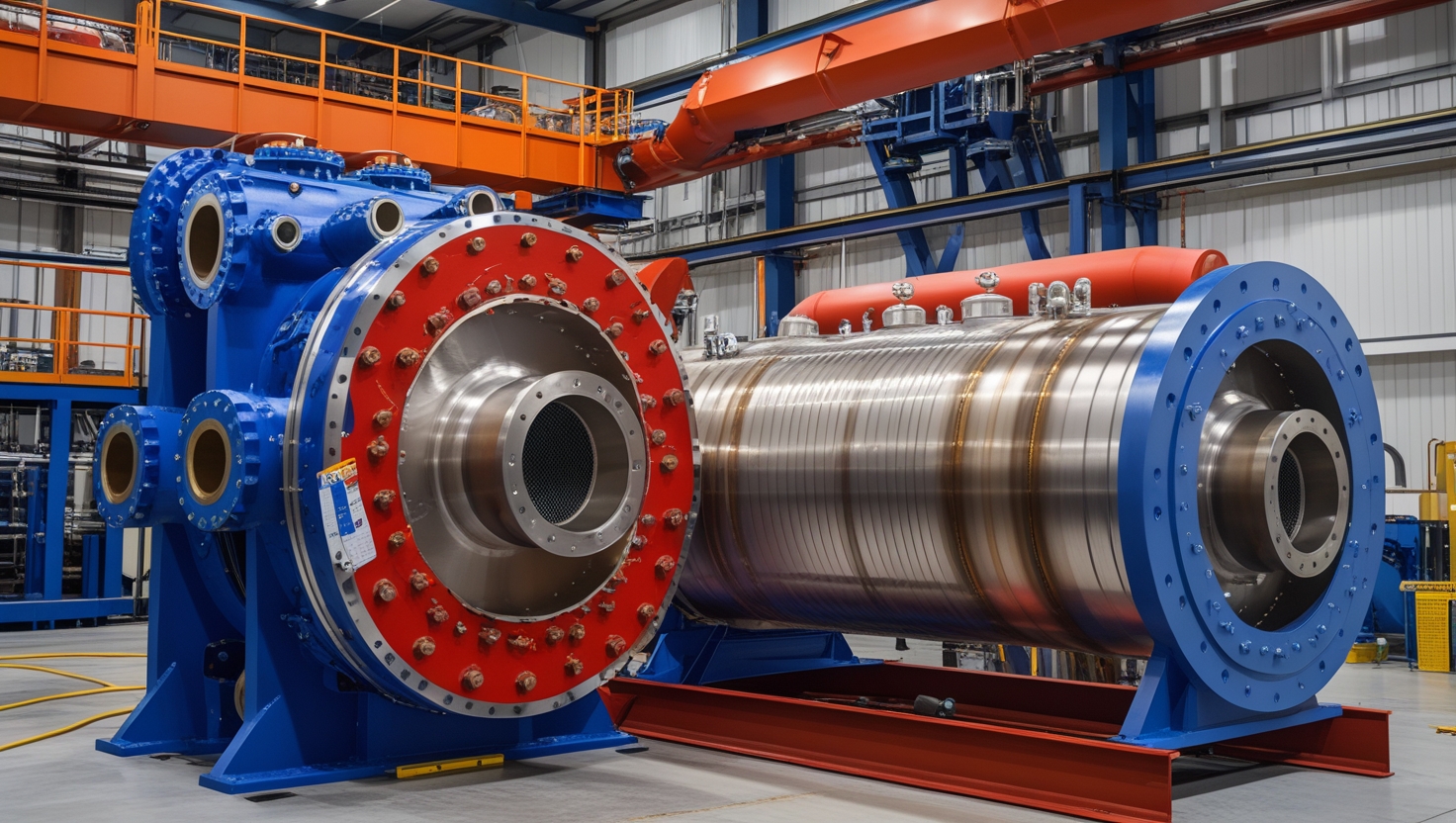

Industrial processes in sectors like chemical manufacturing, petrochemicals, power generation, and pharmaceuticals often involve operating conditions that push the boundaries of material science – extreme temperatures and highly corrosive environments. In these challenging applications, the reliability and lifespan of a heat exchanger depend critically on the materials used for its components, particularly those directly in contact with aggressive fluids.

For purchasers of heat exchangers and spare parts, selecting the right materials for these critical components and sourcing them effectively is paramount to ensuring operational uptime, safety, and achieving the best long-term value. This guide delves into the key components that face these extremes, the specialized materials they require, and practical strategies for sourcing them at a competitive price while ensuring performance.

Identifying Critical Components in Extreme Environments

Within any heat exchanger design (Plate, Shell & Tube, etc.), certain components bear the brunt of harsh operating conditions:

- Heat Transfer Surfaces: These are the primary components designed for heat exchange and are fully exposed to the process fluids. This includes the plates in Plate Heat Exchangers (PHEs) and the tubes in Shell and Tube Heat Exchangers (STHXs). Their integrity is vital for thermal performance and containment.

- Sealing Elements: Components that prevent mixing or leakage between fluids or to the outside environment. In Gasketed PHEs (GPHEs), these are the gaskets. In STHXs and Welded PHEs, this involves welds (e.g., tube-to-tubesheet welds) and other seals. These must maintain their integrity under heat, pressure, and chemical attack.

- Connections and Nozzles: The points where hot and cold fluids enter and exit the heat exchanger. These are also wetted components exposed to process conditions and must withstand mechanical stress and corrosion.

- Tubesheets (STHXs): Thick plates into which the tubes are fastened, forming a critical barrier.

- Baffles (STHXs): While primarily for flow direction and tube support, baffles are also exposed to shell-side fluids.

While the outer shell or frame is important for pressure containment, the materials for the wetted components are the primary concern when dealing with extreme heat and corrosion.

Materials for the Extreme: Matching Components to Conditions

Withstanding extreme temperatures and corrosive chemicals requires materials far beyond standard stainless steels. The selection depends precisely on the type of corrosive media (acids, chlorides, alkalis, solvents), their concentration, temperature, pressure, and potential for impurities or phase changes. Key material categories for critical components include:

- High-Performance Stainless Steels: While standard 304/316 may not suffice, higher grades like Duplex, Super Duplex, and Super Austenitic Stainless Steels (e.g., SMO 254) offer enhanced resistance, particularly against pitting and crevice corrosion in challenging chloride environments, sometimes at elevated temperatures. Used for plates, tubes, and tubesheets.

- Titanium Alloys: Exceptional for handling chlorides (seawater, brines, wet chlorine gas) and oxidizing acids. Commercially Pure Titanium (Grades 1, 2, 7, 12) is common for plates and tubes. They maintain excellent resistance at high temperatures in these specific environments but may be susceptible to certain reducing acids or fluorides.

- Nickel Alloys: A diverse family offering broad resistance to various aggressive chemicals, including reducing acids (sulfuric, hydrochloric), oxidizing acids, and media that cause stress corrosion cracking. Grades like Alloy 400, Alloy 600, Alloy 625, Alloy 800, Alloy 825, and critically, Hastelloy C-276, provide different levels and types of resistance. Hastelloy C-276 is often chosen for its resistance to a very wide range of severely corrosive, mixed chemical streams. Used for plates, tubes, tubesheets, and connections.

- Specialized Gasket Materials (for GPHEs): Standard elastomers fail at high temperatures or with aggressive chemicals. Specialized gaskets made from materials like PTFE (Teflon™), Compressed Non-Asbestos Fiber (CNAF) with specific binders, or Graphite are necessary to maintain a reliable seal under extreme thermal and chemical stress. Their selection is as critical as the plate material.

Performance in the Face of Extremes

Components made from these materials perform by resisting various forms of attack:

- Corrosion Resistance: The primary function – preventing uniform thinning, pitting, crevice corrosion, intergranular attack, and stress corrosion cracking caused by aggressive fluids at high temperatures.

- High-Temperature Strength: Maintaining mechanical integrity and resisting deformation or creep under high thermal stress.

- Resistance to Embrittlement: Avoiding becoming brittle or losing toughness after exposure to high temperatures or specific process conditions.

- Maintaining Seal Integrity: Gaskets and welds must remain leak-tight despite thermal cycling, pressure fluctuations, and chemical degradation.

History & Origins: Materials Engineered for Harshness

The development of these advanced materials is closely tied to the needs of modern industrial processes that emerged in the 20th century, requiring equipment to operate under increasingly severe conditions. While basic heat transfer principles are centuries old, the widespread industrial use of stainless steels grew in the early 20th century, followed by the development of specialized nickel alloys and titanium alloys driven by demands from the aerospace, defense, and chemical processing industries in the mid to late 20th century. Alloys like Hastelloy C-276 were specifically engineered to overcome the limitations of earlier materials in managing highly aggressive and mixed corrosive streams. The origins of these materials trace back to mining operations around the globe for essential elements like Iron, Chromium, Nickel, Molybdenum, Titanium, and Tungsten.

Global Supply Chain: Raw Materials, Producers, and Component Suppliers

The supply chain for high-performance heat exchanger components involves several stages:

- Raw Material Sources: Metals are extracted from ores mined in various countries globally (e.g., Nickel from laterite and sulfide deposits in Indonesia, Philippines, Russia; Titanium from ilmenite/rutile in Australia, South Africa).

- Alloy and Material Producers: Companies specialize in melting, alloying, and processing these raw metals into mill products (sheets, plates, tubes, bars) and specialized forms like gasket sheets. Key players include Haynes International (Hastelloy), Special Metals (various Nickel Alloys), VDM Metals, ATI (Allegheny Technologies), Timet (Titanium), and specialized gasket material manufacturers (like Garlock, Klinger).

- Heat Exchanger Manufacturers (Component Suppliers): Leading heat exchanger manufacturers (like Alfa Laval, GEA, Kelvion, Tranter, Koch Heat Transfer, Chart Industries) purchase these mill products and process them further – pressing plates, fabricating shells/heads, welding tube bundles, and providing certified gaskets. They are often the most reliable source for high-performance components and spare parts specifically designed for their heat exchanger models.

- Specialized Aftermarket Suppliers: Some companies specialize in providing replacement plates, gaskets, or tubes compatible with various OEM heat exchanger models, often sourcing materials from the same or similar reputable alloy producers.

Sourcing Strategies: Getting the Best Price (Value) for Critical Components

Purchasing components and spare parts for heat exchangers in extreme service requires a focus on value, reliability, and compatibility over simply finding the lowest upfront price.

- Accurate Identification & Specification: Ensure you know the exact heat exchanger model, the specific component needed (e.g., plate model, tube dimensions, gasket type), and the precise material specification. For high alloys, variations in grade or composition matter significantly. Work with suppliers who can help verify the correct part and material for your unit and service conditions.

- Match Material to the Exact Conditions: Do not guess on the material. Revisit process conditions (temperature, concentration, potential impurities) and corrosion data. Avoid over-specifying (paying for resistance you don’t need), but absolutely avoid under-specifying (leading to rapid failure). Consult with suppliers who have metallurgical expertise.

- Source from Reputable Suppliers (OEM or Certified Aftermarket): For critical components in severe service, the origin and quality certification of the material and fabrication are paramount. Sourcing from the Original Equipment Manufacturer (OEM) or a well-established, certified aftermarket supplier ensures the component meets design specifications and material integrity standards. Cheap, unverified sources for high-alloy components or specialized gaskets carry a high risk of premature failure, leading to costly downtime and safety hazards.

- Focus on Total Cost of Ownership (TCO): Consider the component’s expected lifespan in service, replacement cost (part price + labor), and the cost of downtime required for replacement. A higher-priced component with a significantly longer lifespan and lower failure risk often provides a much better TCO.

- Evaluate Supplier Expertise and Support: Can the supplier provide material certifications? Do they offer technical support for installation or troubleshooting? Do they have a track record with these specific materials in similar applications? Their knowledge is part of the value.

- Plan for Lead Times: High-performance alloy components often have longer manufacturing lead times due to material availability and complex fabrication. Plan your spare parts inventory strategically to avoid emergency shutdowns.

- Negotiate Based on Volume/Relationship: For ongoing spare parts needs, discuss potential volume discounts or long-term supply agreements with your preferred supplier.

Main Heat Exchanger Manufacturers: Suppliers of High-Performance Units and Components

Several global companies are renowned for manufacturing heat exchangers capable of handling extreme conditions, offering units and components made from high-performance alloys. These suppliers vary in their specific product lines (STHX, different PHE types, etc.), industry focus, and alloy expertise. Prominent names in the industry include Alfa Laval, GEA, Kelvion, Tranter, Koch Heat Transfer, and Chart Industries, among many others. These manufacturers are the primary source for certified, model-specific components like high-alloy plates, tubes, and specialized gaskets needed for units operating in severe service environments.

Navigating the offerings and strengths of these major manufacturers, and ensuring you source the exact certified component needed for your specific heat exchanger model and challenging conditions, requires expertise. HeatingFormula can assist you in this process, guiding you through the options from various suppliers to ensure you get the right certified components for your heat exchanger.

Conclusion

Ensuring reliability and safety in heat exchange applications involving extreme heat and corrosive fluids hinges on the performance of critical components like plates, tubes, tubesheets, and seals. Materials such as high-performance stainless steels, Titanium alloys, and Nickel alloys like Hastelloy C-276 are engineered to withstand these conditions, but selecting and sourcing them effectively requires expertise. For purchasers, focusing on accurate material specification, understanding total cost of ownership, and partnering with reputable suppliers are key strategies for obtaining the best value for these essential, high-performance components.

Navigating the complex world of high-performance heat exchanger components and spare parts requires specialized knowledge. At HeatingFormula, we possess deep expertise in materials for extreme service and can assist you in identifying the correct components and materials for your specific heat exchanger models and challenging operating conditions. We help you source certified, reliable components, ensuring optimal performance, longevity, and value for your investment. Explore our guide covering GPHE Selection (which includes material considerations), Contact us directly for expert consultation on high-temperature and corrosive service components, and learn about our offering of GPHE Spare Parts for these specialized units.

Frequently Asked Questions (FAQ) About High-Performance Components

Which components fail most often in heat exchangers exposed to extreme corrosion or heat?

The components in direct contact with the fluids are most vulnerable: heat transfer surfaces (plates/tubes) and sealing elements (gaskets/welds). Connections and tubesheets can also be critical failure points.

Why is TCO important when buying spare parts for heat exchangers in severe service?

The cost of the spare part itself is often minor compared to the cost of labor for replacement, lost production due to downtime, and potential safety or environmental impacts if a critical component fails unexpectedly. TCO considers all these factors over the component’s expected lifespan.

Should I buy non-OEM spare parts for high-pressure/corrosive service heat exchangers?

Caution is strongly advised. While some aftermarket suppliers are reputable, using components that are not certified to meet the exact material specifications, tolerances, and quality standards (like NDT for welds) of the OEM can lead to premature failure. Verify quality control and material certifications rigorously if considering non-OEM sources for critical applications.

What determines the type of gasket material needed for a GPHE in harsh service?

The gasket material selection is based on the maximum operating temperature, the maximum operating pressure, and the chemical compatibility with the fluids on both sides of the heat exchanger. Specialized materials like PTFE, Graphite, and certain high-performance elastomers are needed for extreme conditions.

Where can I source reliable high-alloy PHE spare parts like plates and gaskets?

The most reliable source is typically the Original Equipment Manufacturer (OEM) of your heat exchanger. Some specialized aftermarket suppliers also offer certified parts. It is crucial to work with suppliers who can provide material certifications and guarantee compatibility with your specific unit.