Introduction to Plate Heat Exchangers

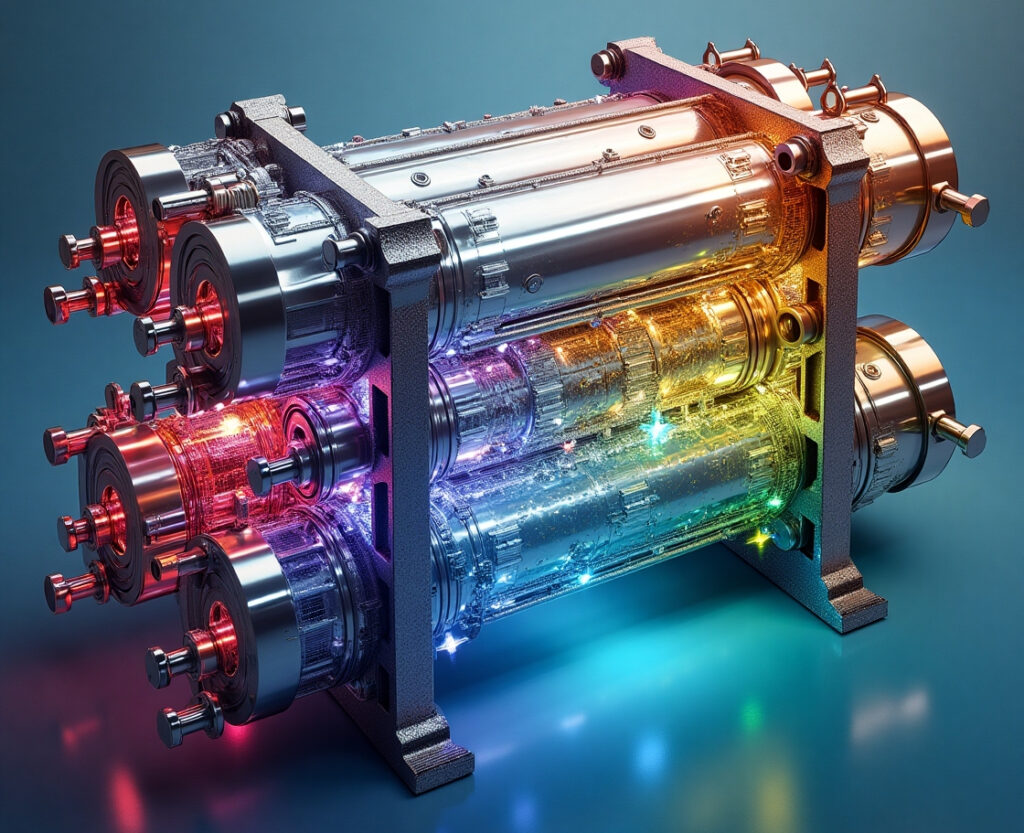

Plate heat exchangers (PHEs) are highly efficient systems used for transferring heat between two or more fluids. They consist of a series of thin, corrugated plates stacked together in a frame, creating channels for fluid flow. This design maximizes the surface area available for heat transfer while minimizing the volume and material required, making PHEs an attractive option across various industries such as food processing, chemical production, and HVAC (heating, ventilation, and air conditioning).

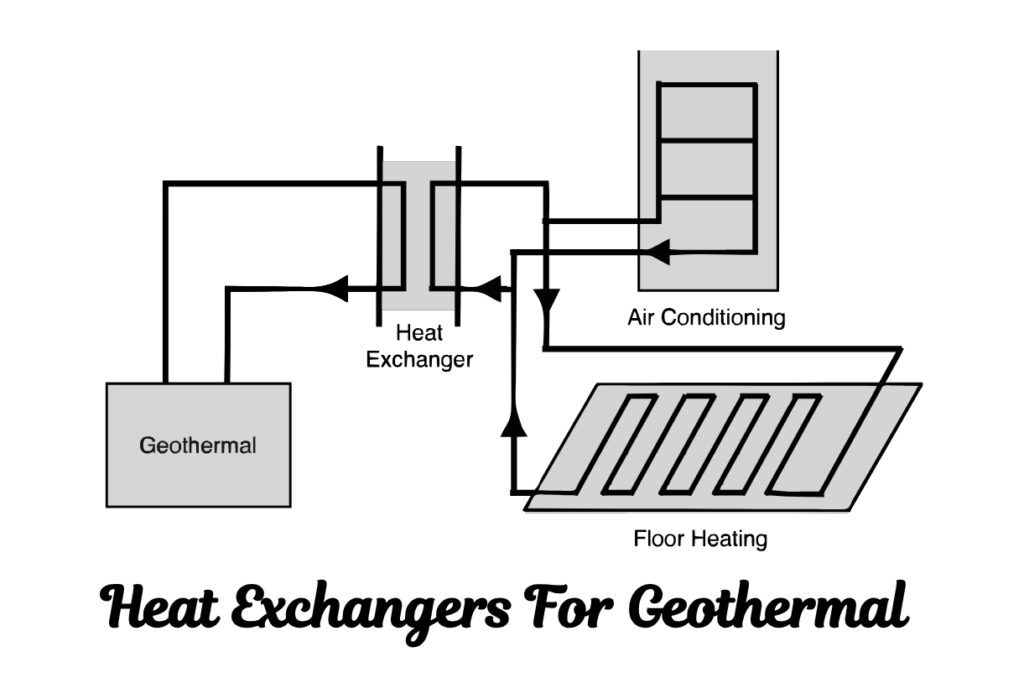

The operational principle of plate heat exchangers is based on the counterflow or parallel flow configuration. In a counterflow arrangement, the fluids move in opposite directions, enhancing heat transfer efficiency. As the hot fluid transfers heat to the cold fluid through the plates, both fluids exit the exchanger at different temperatures, achieving a highly efficient heat exchange process. The use of plates rather than tubes or shells allows for better thermal performance and a compact design, making them well-suited for applications where space is a concern.

A notable feature of plate heat exchangers is their key components: plates, gaskets, and frames. The plates are typically made of stainless steel or other corrosion-resistant materials, each featuring a specific pattern to create turbulence and facilitate efficient heat transfer. Gaskets, which seal the plates together, prevent leakage and ensure that the fluids do not mix, thereby maintaining the effectiveness of the heat exchange process. Finally, the frame provides structural integrity and allows for the easy disassembly of the plates for maintenance or cleaning, an essential feature in industries that prioritize hygiene and safety.

In essence, plate heat exchangers stand out in the market due to their versatility and robustness. Their ability to adapt to various applications while offering high thermal efficiency differentiates them from traditional heat exchanger systems. This foundational understanding of plate heat exchangers sets the stage for exploring their increasing adoption and the associated benefits that contribute to their rising popularity.

Advantages of Plate Heat Exchangers

Plate heat exchangers have garnered significant attention in recent years due to their numerous advantages, making them a preferred choice in multiple industries. One of the main benefits is their high thermal efficiency, which arises from their substantial surface area and the thin plates that facilitate effective heat transfer. This results in improved energy efficiency and lower operational costs compared to traditional shell-and-tube heat exchangers.

The compact design of plate heat exchangers allows for a smaller footprint, which is particularly advantageous in environments where space is at a premium. Due to their modular nature, these systems can easily be expanded or modified to meet changing processing demands. This flexibility makes them suitable for a wide variety of applications, including in the food and beverage industry, pharmaceuticals, HVAC systems, and chemical processing facilities. For instance, in the food sector, plate heat exchangers are frequently utilized for pasteurization processes, where efficient heat transfer is vital for maintaining product quality and safety.

Another compelling advantage is the ease of maintenance associated with plate heat exchangers. The design allows for easy access to individual plates, simplifying cleaning and inspections. This accessibility reduces downtime, promoting continual and efficient operation. Furthermore, many manufacturers have introduced materials and coatings that enhance the corrosion resistance of these heat exchangers, extending their operational lifespan and reducing replacement costs.

Real-world examples demonstrate the effectiveness of plate heat exchangers across various applications. In pharmaceutical processing, for instance, these systems not only contribute to energy savings but also ensure that critical temperature controls are maintained. Similarly, in HVAC applications, their ability to manage heat transfer efficiently leads to improved climate regulation in buildings. Overall, the advantages of plate heat exchangers offer significant benefits that result in lower energy costs and enhanced operational efficiency across diverse sectors.

Technological Advancements Driving Adoption

Plate heat exchangers have seen significant transformations in recent years, driven by technological advancements that enhance their performance and reliability. One of the key improvements is the development of innovative materials that increase durability and efficiency. Manufacturers are now utilizing advanced alloys and composites that withstand high pressures and corrosive environments, leading to prolonged service life and reduced maintenance costs. These materials not only enhance thermal conductivity but also promote better heat transfer efficiency, making plate heat exchangers an attractive option for industries ranging from food processing to chemical manufacturing.

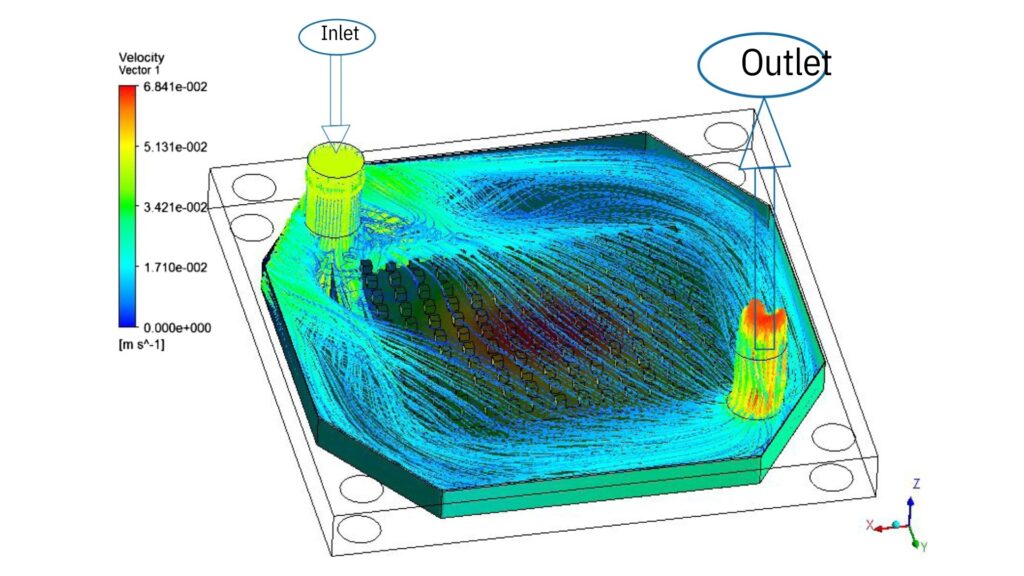

In addition to material enhancements, the incorporation of digital monitoring systems has revolutionized the operation of plate heat exchangers. Modern heat exchangers are equipped with sensors and IoT devices that enable real-time performance monitoring and data collection. This digital integration allows users to track parameters such as temperature, flow rates, and pressure levels, providing insights into operational efficiency. Consequently, businesses can optimize their processes, identify potential issues before they escalate, and make informed decisions regarding maintenance and repairs. The convenience of remote monitoring also contributes to increased operational uptime, making plate heat exchangers even more appealing.

Furthermore, advancements in manufacturing techniques have streamlined production processes, reducing costs and improving the scalability of plate heat exchangers. Innovations such as laser welding and automated assembly have enhanced precision and consistency, which is critical for ensuring optimal performance. These techniques not only enhance the quality of the final product but also allow for the customization of designs to meet specific operational needs. As a result, both large enterprises and small businesses can benefit from tailored solutions without incurring prohibitive costs.

Overall, the fusion of advanced materials, digital monitoring, and cutting-edge manufacturing technologies plays a significant role in boosting the reliability, longevity, and efficiency of plate heat exchangers. This evolution makes them increasingly attractive for a wide array of applications across various industries.

Market Trends and Future Outlook

The market for plate heat exchangers has been experiencing significant growth, primarily driven by an increasing demand for energy-efficient solutions across various industries. Energy efficiency regulations have become more stringent globally, compelling organizations to adopt technologies that minimize energy consumption and reduce operational costs. Plate heat exchangers, known for their compact design and superior thermal performance, enable industries such as food and beverage, pharmaceuticals, and HVAC systems to achieve these objectives effectively.

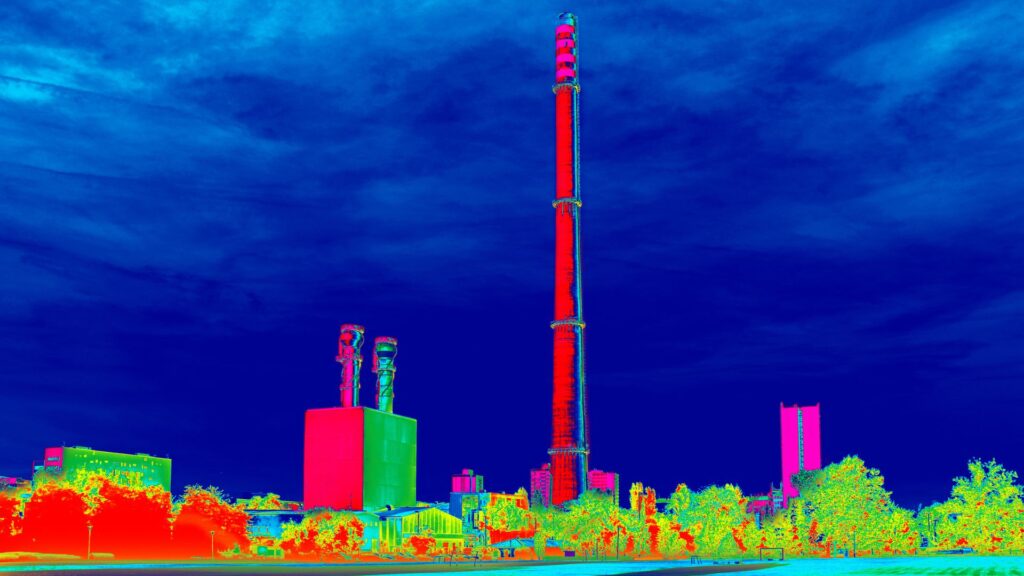

Sustainability has emerged as a pivotal factor influencing the adoption of plate heat exchangers. As businesses pivot towards environmentally friendly practices, the demand for equipment that contributes to energy conservation and waste reduction has surged. These heat exchangers facilitate the recycling of thermal energy, thus lowering greenhouse gas emissions and aligning with sustainability initiatives. The intersection of regulatory mandates and corporate social responsibility is expected to further catalyze market growth, as companies embrace innovations that meet both compliance and ethical performance metrics.

The competitive landscape for plate heat exchangers is marked by several key players focusing on expanding their market presence through strategic collaborations, technological advancements, and innovative product developments. Major manufacturers are investing heavily in research and development to improve the efficiency and longevity of their products, enabling them to better cater to the needs of various sectors. This proactive approach not only bolsters their market position but also ensures that advancements in plate heat exchanger design are closely aligned with evolving industry requirements.

Looking ahead, the future of plate heat exchangers is shaped by their potential role in addressing climate change challenges. As industries continue to seek solutions that support energy conservation efforts, plate heat exchangers are likely to see enhancements in their design aimed at improving efficiency further. This will facilitate their use in diverse applications, reinforcing their importance in the global transition towards more sustainable practices.